Surface modified lithium battery high-nickel anode material and preparation method thereof

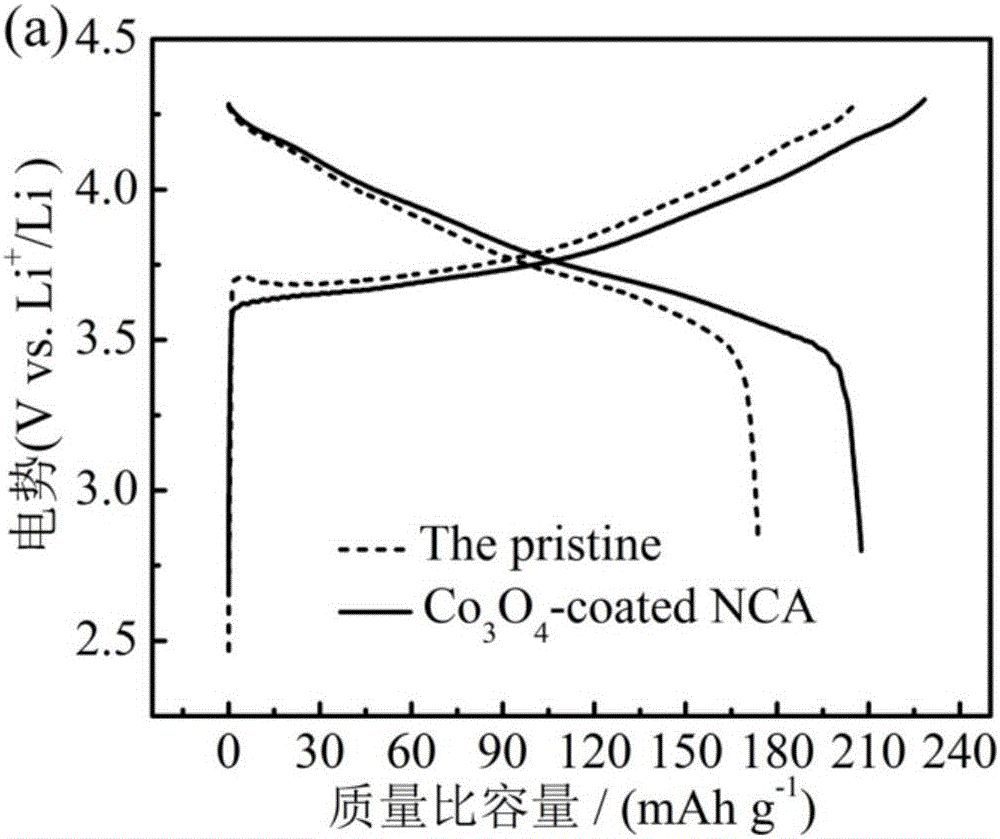

A positive electrode material and surface modification technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle performance and low first-cycle efficiency, and achieve improved discharge specific capacity, improved charge and discharge efficiency, and improved cycle performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a surface-modified lithium battery high-nickel cathode material, comprising the following steps:

[0036] (a) Take a certain amount of transition metal salt and high-nickel positive electrode material, described transition metal salt (for example: inorganic salts such as nitrate, carbonate, phosphate, chloride, or organic salts such as acetate) and The mass ratio of the high-nickel cathode material is 100:0.5~100:5;

[0037] Wherein, the transition metal element in the transition metal salt is one of Co, V, Fe, Mn, Ni, Zn, Y, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Cd; Nickel cathode material is LiNi x co y m z o 2 , where 0.6≤x≤1, 0≤y≤0.4, 0≤z≤0.4, and x+y+z=1, M is one or more of Mn, Al, Mg, Ti;

[0038] (b) dissolving the transition metal salt in a certain amount of deionized water or absolute ethanol, fully stirring until completely dissolved;

[0039] (c) dripping the prepared transition metal salt solution into the high-nick...

Embodiment 1

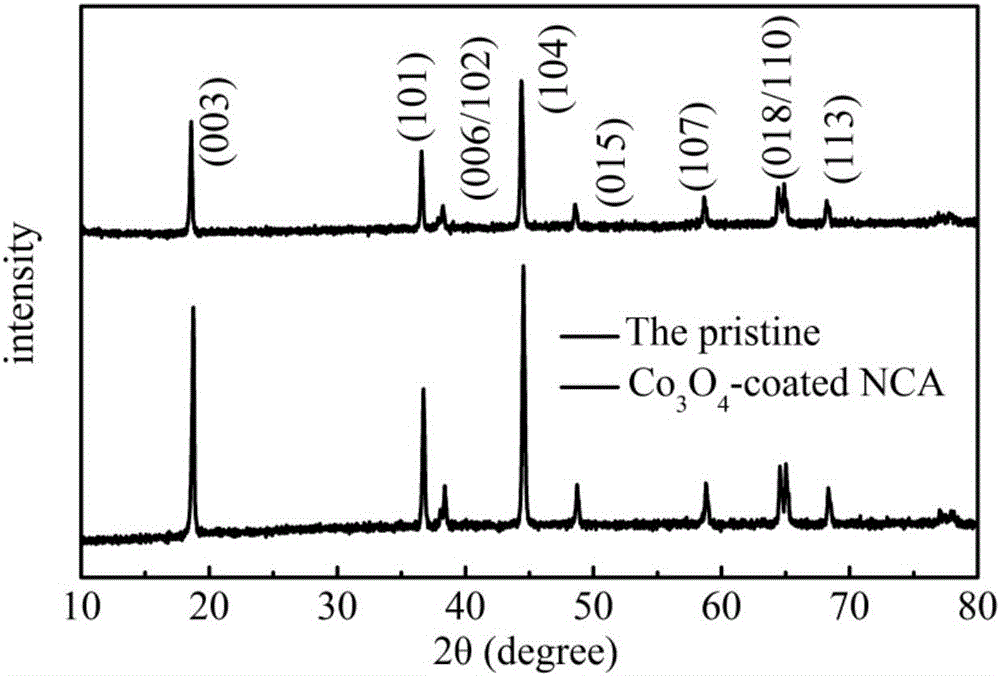

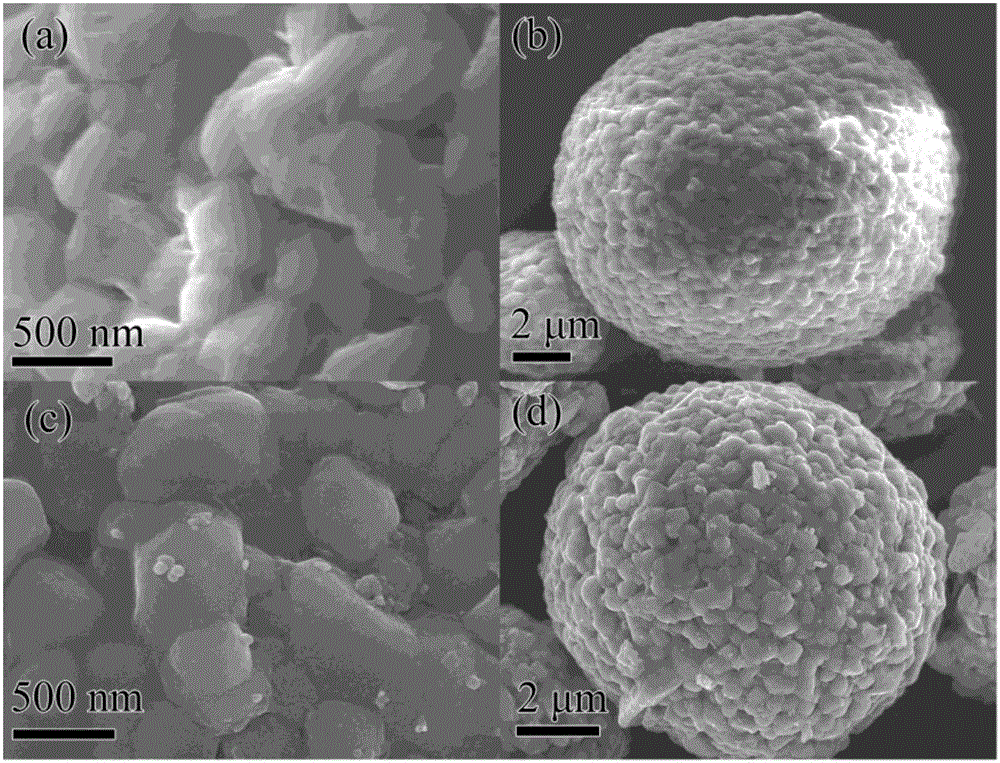

[0049] Weigh 0.5g of LiNi 0.8 co 0.15 al 0.05 o 2 , according to Co:LiNi 0.8 co 0.15 al 0.05 o 2 The ratio is 1:100. Weigh cobalt nitrate hexahydrate, dissolve cobalt nitrate hexahydrate in absolute ethanol at a concentration of 0.01mol / L, stir until completely dissolved, and obtain cobalt nitrate ethanol solution. Add cobalt nitrate ethanol solution dropwise to LiNi 0.8 co 0.15 al 0.05 o 2 in, until just submerged LiNi 0.8 co 0.15 al 0.05 o 2 powder, will immerse LiNi 0.8 co 0.15 al 0.05 o 2 Put the powder in an oven at 80°C for drying, repeat the dripping drying process, then continue drying the material for 12 hours, grind the dried material for 45 minutes, and finally put the processed material in an air furnace at 600°C Processing 2h.

Embodiment 2

[0051] Weigh 0.5g of LiNi 0.6 co 0.2 mn 0.3 o 2 , according to Co:LiNi 0.6 co 0.2 mn 0.3 o 2 The ratio is 0.5:100. Weigh cobalt nitrate hexahydrate, dissolve cobalt nitrate hexahydrate in deionized water at a concentration of 0.01mol / L, and stir until completely dissolved to obtain a cobalt nitrate solution. Add cobalt nitrate solution dropwise to LiNi 0.6 co 0.2 mn 0.3 o 2 in, until just submerged LiNi 0.6 co 0.2 mn 0.3 o 2 powder, will immerse LiNi 0.6 co 0.2 mn 0.3 o 2 Dry the powder in an oven at 60°C, repeat the dripping drying process, then continue drying the material for 24 hours, grind the dried material for 30 minutes, and finally put the processed material in an air furnace at 400°C Processing 5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com