Welding spot data processing method and system

A data processing system and data processing technology, applied in data processing applications, electrical digital data processing, natural language data processing, etc., can solve problems such as poor versatility and interactivity, single function, and difficulty in meeting the data processing requirements of spot welding processes. , to achieve the effect of strong versatility and interactivity, easy to use, and good visual interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0113]In view of the lack of solder joint data processing software in the prior art, poor versatility and interactivity, inconvenient use and single function, the present invention proposes a solder joint data processing method and system, using programming interfaces such as design or simulation software or Input and output files, complete the automatic processing of solder joint data in software such as CATIA, EXCEL, and ROBCAD (or PD), and provide a complete set of solutions for the transfer of solder joint data between these software.

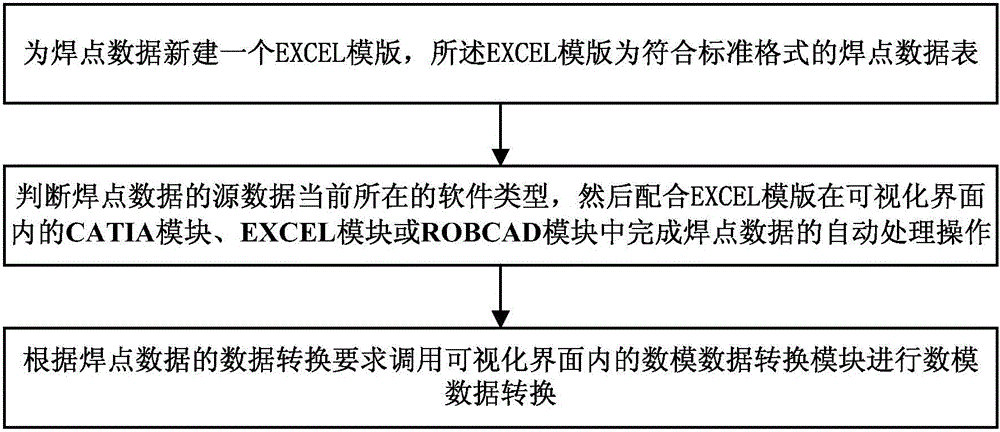

[0114] Solder spot data processing method of the present invention mainly comprises the following steps:

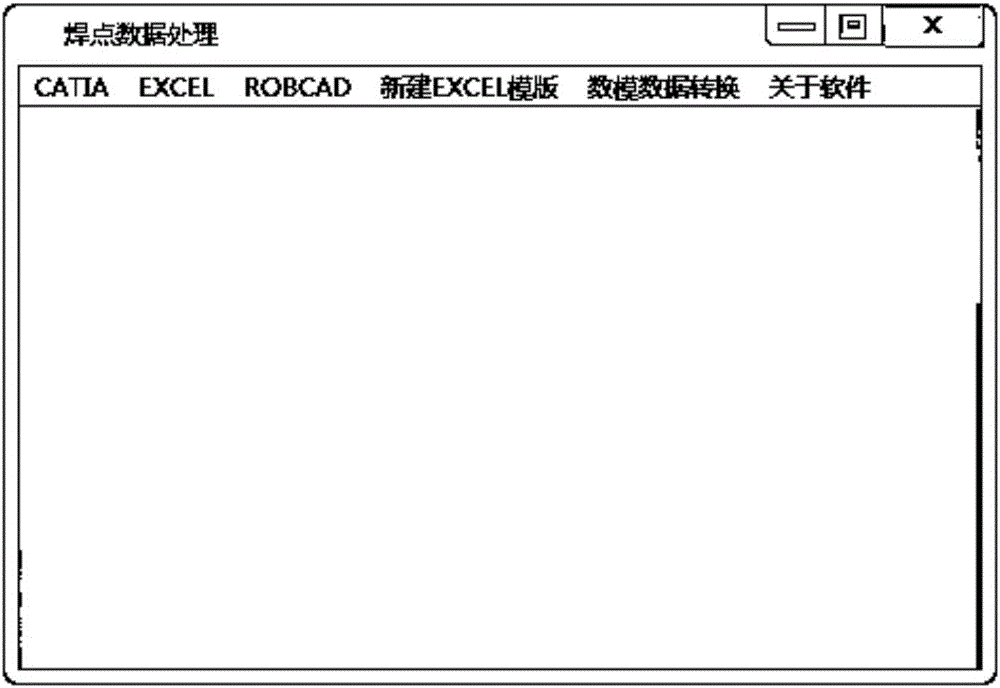

[0115] First, establish a standard template for the representation of solder joint data in EXCEL. Such as figure 2 As shown, the visual interface contains the menu command "New EXCEL Template", which is used to create a new solder joint data table conforming to the standard format.

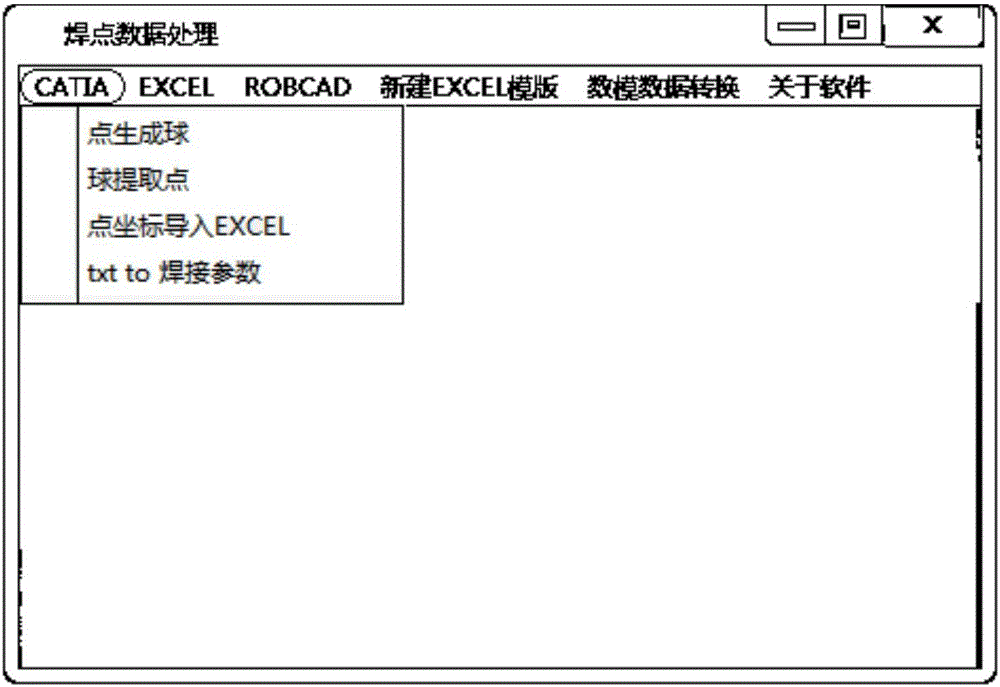

[0116] Then, according to which software the sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com