Method for evaluating high-temperature performance of hot pouring type crack pouring sealant

A technology of high temperature performance and seam filling glue, applied in the direction of material inspection products, etc., can solve the problem that the high temperature performance of seam filling glue cannot be well reflected, and achieve the effect of easy equipment and test environment, and clear test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

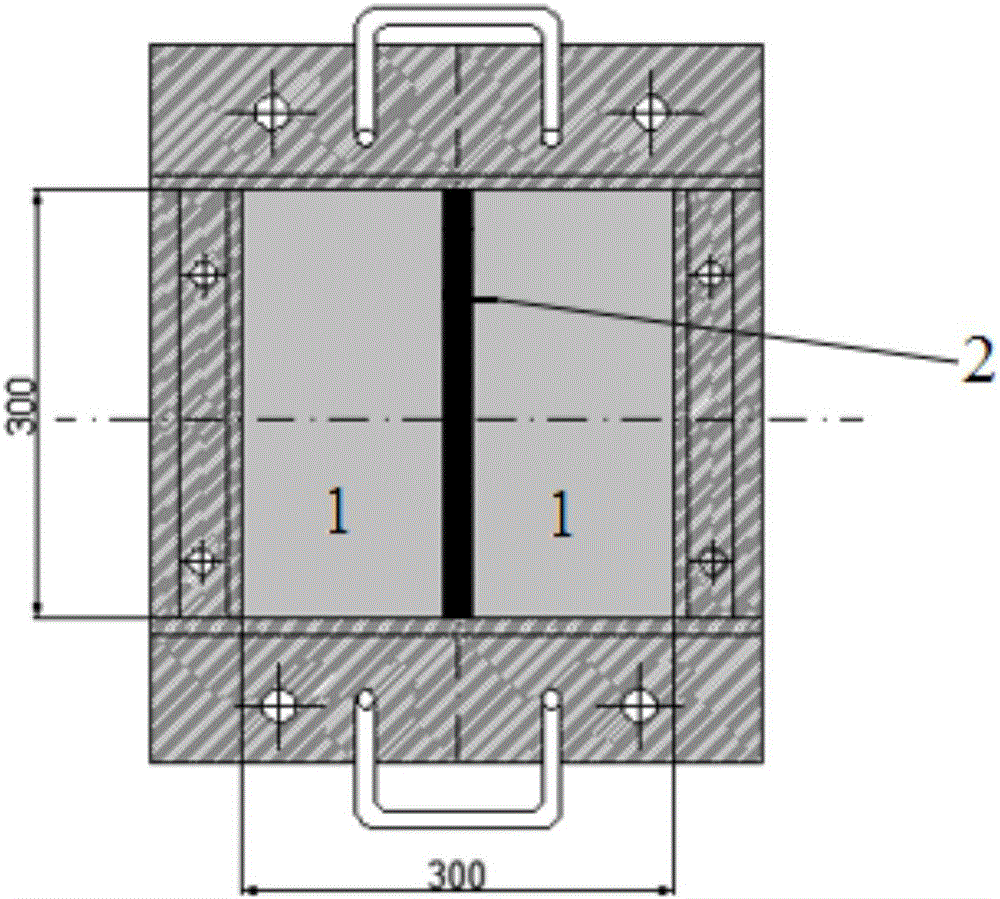

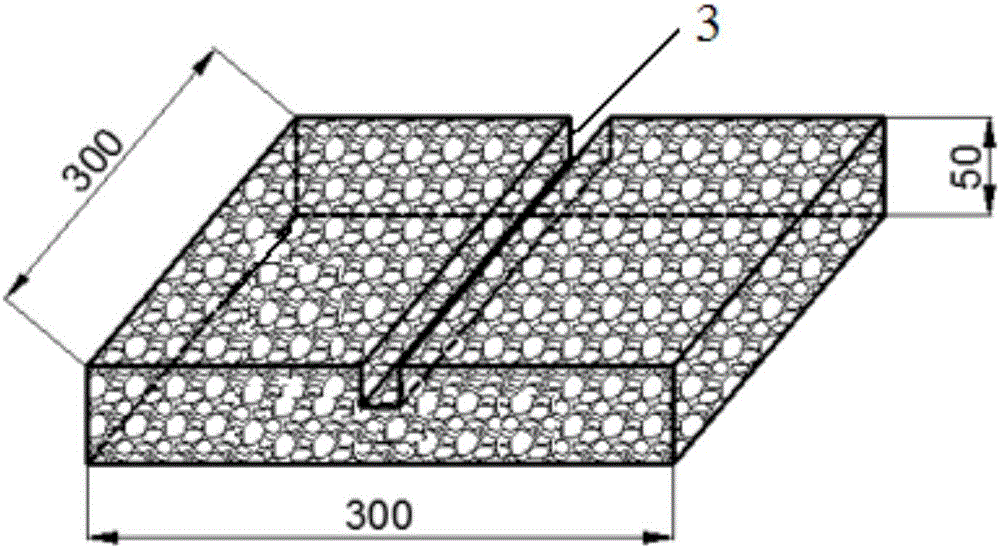

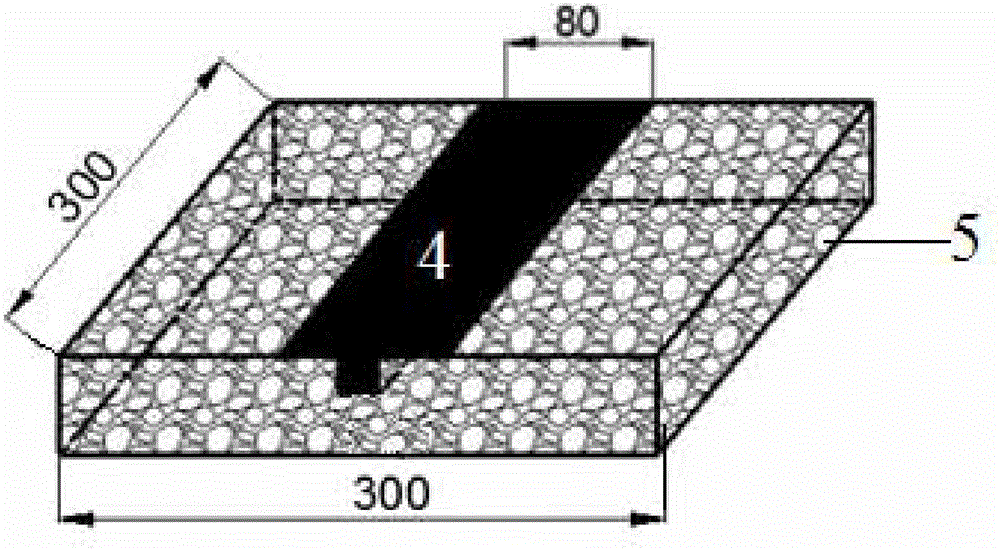

[0024] Specific implementation mode one: combine Figure 1-6 , this embodiment is a method for evaluating the high-temperature performance of hot-filling joint-filling glue, which is specifically carried out according to the following steps:

[0025] 1. Pavement basic data survey: investigate and obtain the basic data of the actual asphalt pavement;

[0026] 2. Preparation of rutting slabs: prepare asphalt mixture with the same basic data according to the basic data of the actual asphalt pavement obtained in step 1, then put it into the mold, and prepare a 300mm× 300mm×50mm rectangular rutting plate specimen, and there is a rectangular parallelepiped groove at the center line of one of the surfaces with a size of 300mm×300mm to simulate cracks on the asphalt pavement. The length of the rectangular parallelepiped groove is 300mm, and the width and depth are the same as the actual The width and depth of the slotting and slotting of the asphalt pavement are the same, and the cen...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the basic data of the asphalt pavement described in step 1 is the type of asphalt pavement surface layer mixture, the gradation of the asphalt mixture, and the type of aggregate in the mixture and grades of asphalt mixtures. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the mold described in step two is a hollow cuboid without a cover, the depth of the inner hollow is 50mm, and the length and width are 300mm. A bump is set in the middle of the bottom surface, the length of the bump is 300mm, and the width and height of the bump are respectively the same as the width and depth of the actual asphalt pavement groove. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com