Tunnel type fruit and vegetable drying chamber and fruit and vegetable drying method

A drying room and tunnel-type technology, applied in the drying room field, can solve the problems of non-circulating air flow and large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

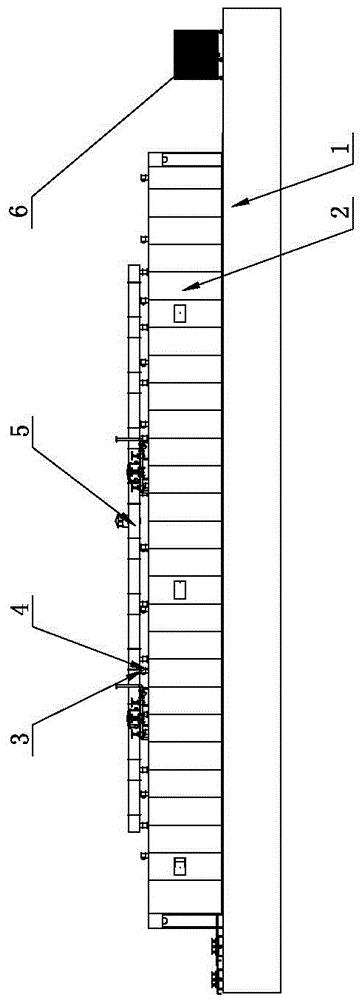

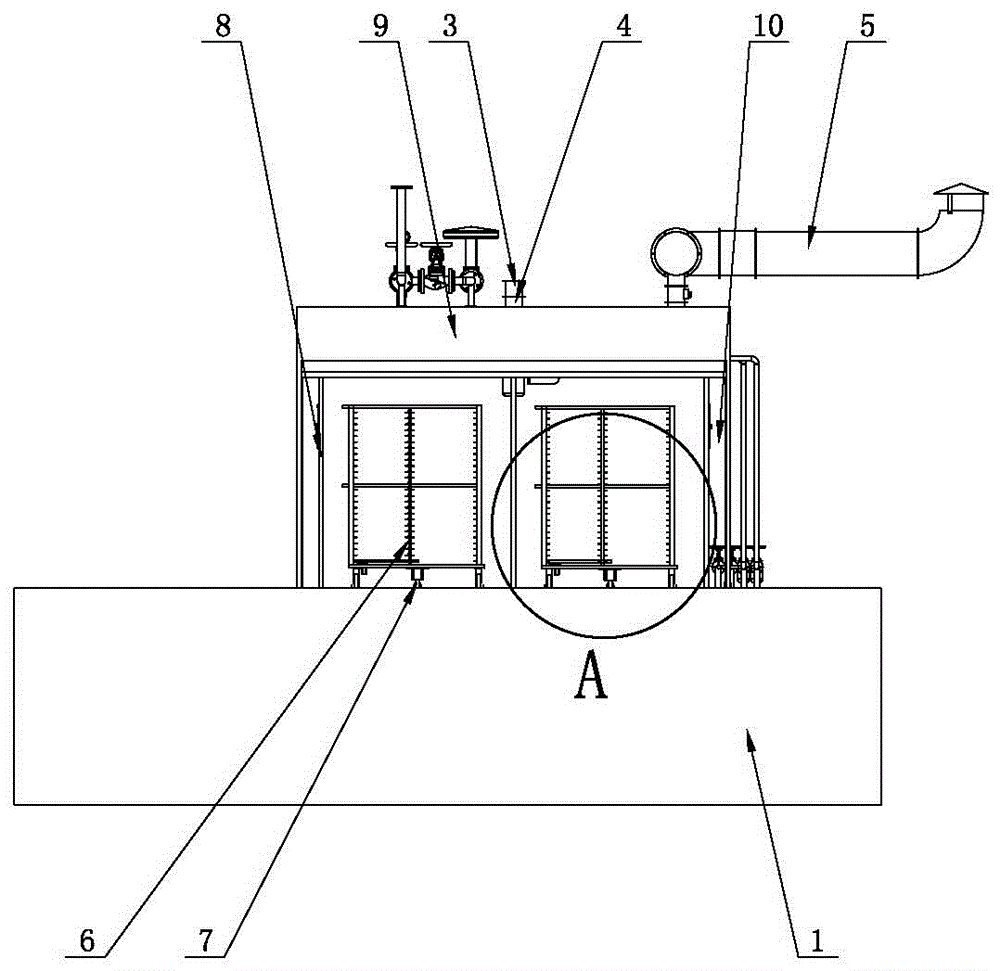

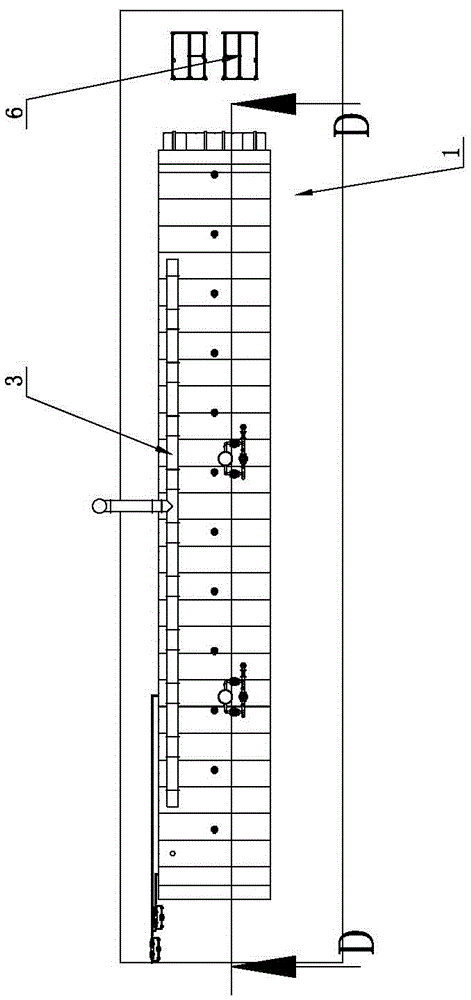

[0037] Such as Figure 1-14 The shown tunnel-type fruit and vegetable drying room includes a drying room set on a base 1. In order to reduce heat loss, an insulation layer is also provided on the base 1, and a driving drying car 6 is provided on the base 1 to enter and exit. The driving mechanism of the drying chamber. The drying chamber includes an outer box body 2 and an inner box body 8. There is a circulating air duct 10 between the outer box body 2 and the inner box body 8. The circulating air duct 10 is located in the inner box body 8. A number of circulating fans 18 are provided on the top, and a heater 17 is provided corresponding to the circulating fan 18. The circulating fan 18 is arranged in the center of the top of the inner box 8, and the heater 17 is arranged in the wind front passage or the wind rear passage of the circulating fan 18 One end of the circulating fan 18 faces the inner box 8, and the other end of the circulating fan 18 is provided with a V-shaped ai...

Embodiment 2

[0041] The difference from the method in Example 1 is that the switchable door 9 is always open, and the driving mechanism gradually pushes into the drying cart 6 containing the materials to be dried, and at the same time, the corresponding dried and cooled drying cart is pushed out 6.

Embodiment 3

[0043] Such as Figure 15 The difference between the tunnel-type fruit and vegetable drying room shown in Embodiment 1 is that the circulating air outlet 15 is rectangular.

[0044] The present invention is not limited to the above-mentioned embodiments. It should be noted that the humid air exhaust device 5 corresponding to each unit section can respectively exhaust the humid air, or can be combined to exhaust the drying chamber, and the exhaust steam assembly connected to the heater 17 23. Excess steam can be discharged separately, or the excess steam can be collected and discharged out of the drying room. In addition, the realization of drying fruits and vegetables is not limited to using the steam pipe 22 to input the dried heat into the drying room to dry the fruits and vegetables. Use other heat-conducting oil circuits to dry fruits and vegetables. The air curtain fan can also be completely or partially replaced by an isolation door. Heating and humidity control devices can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com