Welding-free type coaxial pipe

A coaxial tube, welding-free technology, applied in the direction of tube components, etc., can solve the problems of high cost, low welding efficiency, and lack of versatility of tooling, so as to solve welding plugging, solve versatility, improve production efficiency and product qualification rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

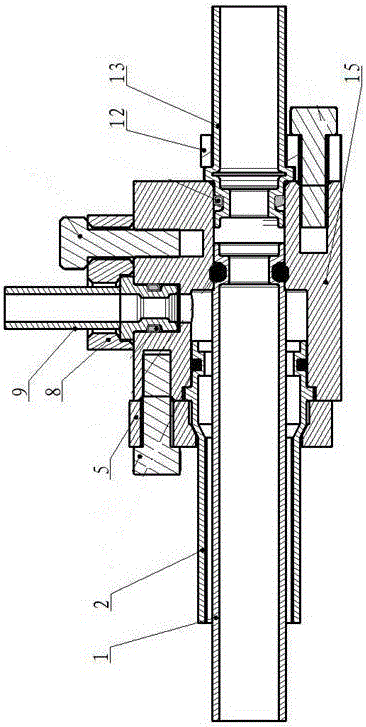

[0014] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] see figure 1 , the low-pressure inlet pipe 1 is inserted into one end of the connector 15, and is sealed with the connector 15 through an O-ring; Compress and lock and fix with bolts; the inner-toothed high-pressure inlet pipe 2 is set on the low-pressure inlet pipe 1 and inserted into the connector 15, the inner-toothed high-pressure inlet pipe 2 and the connector 15 are sealed by an O-ring, and the inner-toothed high-pressure inlet pipe 2 and the low-pressure inlet pipe 1 are compressed by the left pressure plate 5 and fixed by bolts; the high-pressure outlet pipe 9 is inserted into the upper end of the connector 15, and is sealed with the connector 15 through the O-ring 7, and the upper pressure plate 8 presses the high-pressure outlet pipe 9 Tighten and secure with bolts

[0016] When working, the low-temperature and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com