Passive fast automatic shut-off valve inducting shock wave

An automatic cut-off and shock wave technology, applied in the direction of balance valve, valve device, safety valve, etc., can solve the problems of high operator requirements, burning or explosion, waste of time, etc., to reduce complexity and maintenance difficulty, simple and reasonable structure, The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

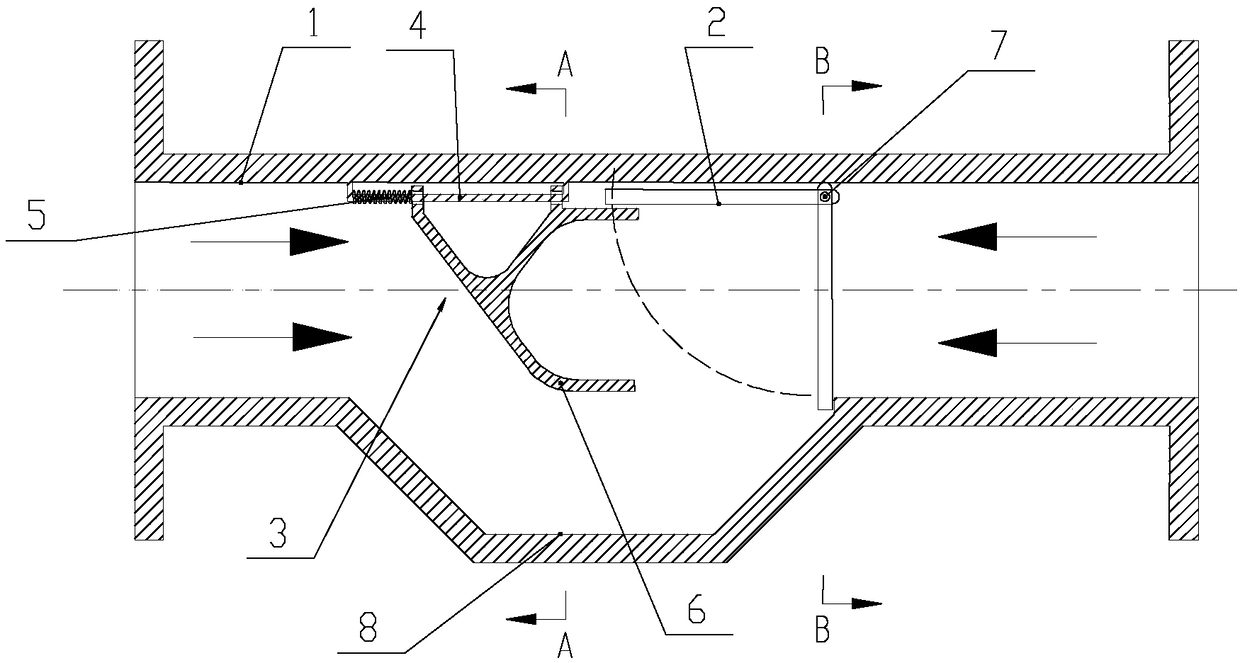

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

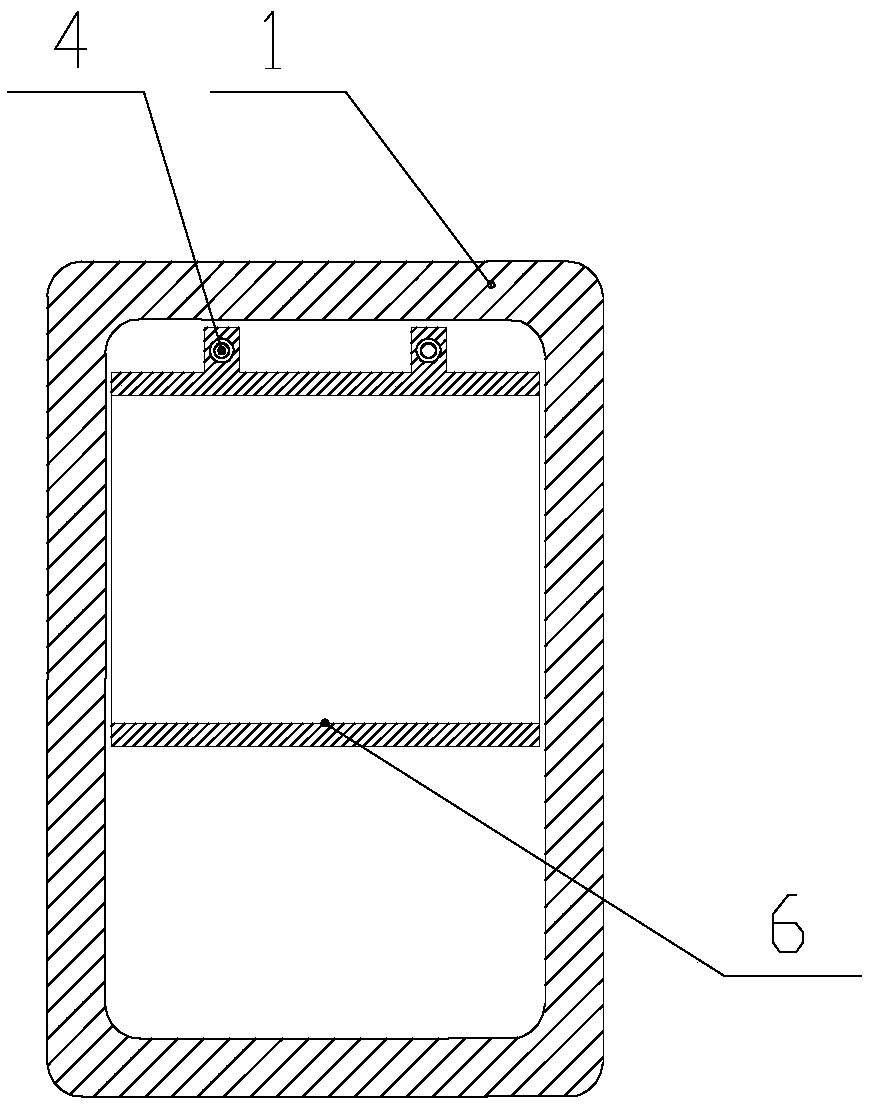

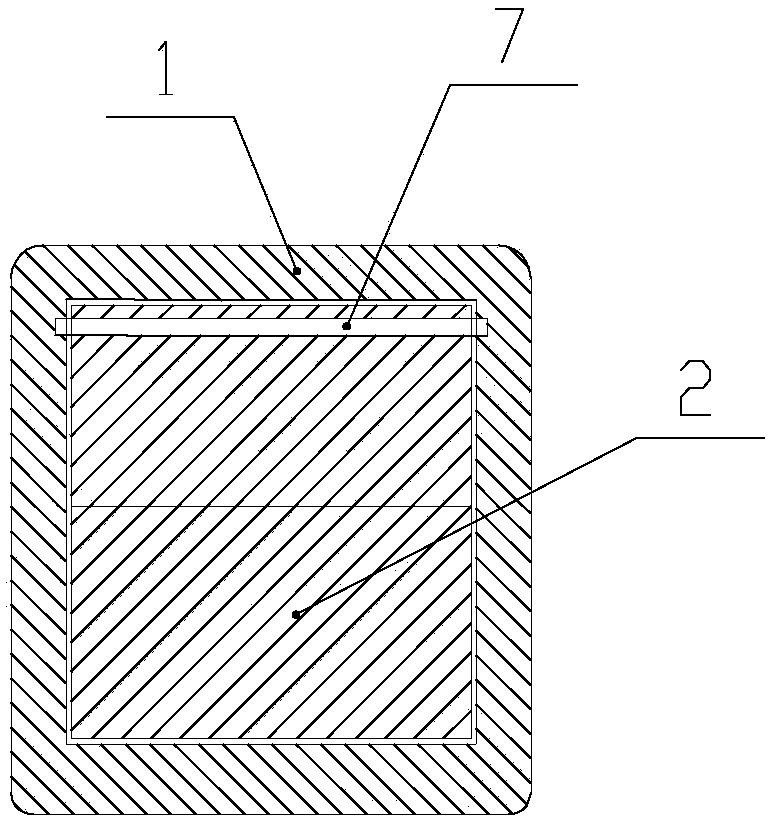

[0018] Such as figure 1 with figure 2 As shown in the present invention, a passive fast automatic cut-off valve inductive to shock waves includes a valve body 1 , a valve plate 2 , a shock wave trigger device 3 , a guide rail 4 , a limit spring 5 and a shock wave plate 6 . The cross-sectional shape of the valve plate 2 is consistent with the shape of the valve port of the valve body 1 , and the valve plate 2 is rotatably connected with the valve body 1 through the rotating shaft 7 . In order to further enhance the sealing performance of the valve plate, a sealing strip for sealing can be provided on the periphery of the valve plate.

[0019] The shock wave trigger device 3 of the present invention includes a guide rail 4 , a limit spring 5 and a shock wave plate 6 . Wherein, the guide rail 4 is arranged on the valve body 1 , the limit spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com