A combined spring sleeve assembly for aircraft wheels

A spring sleeve and combined technology, which is applied in the direction of spring/shock absorber, coil spring, mechanical equipment, etc., can solve the problems that the piston cannot be reset, the hidden danger of accidents, and the brake cannot be completely released, so as to reduce the number of parts, operate reliably, The effect of improving product technical performance and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

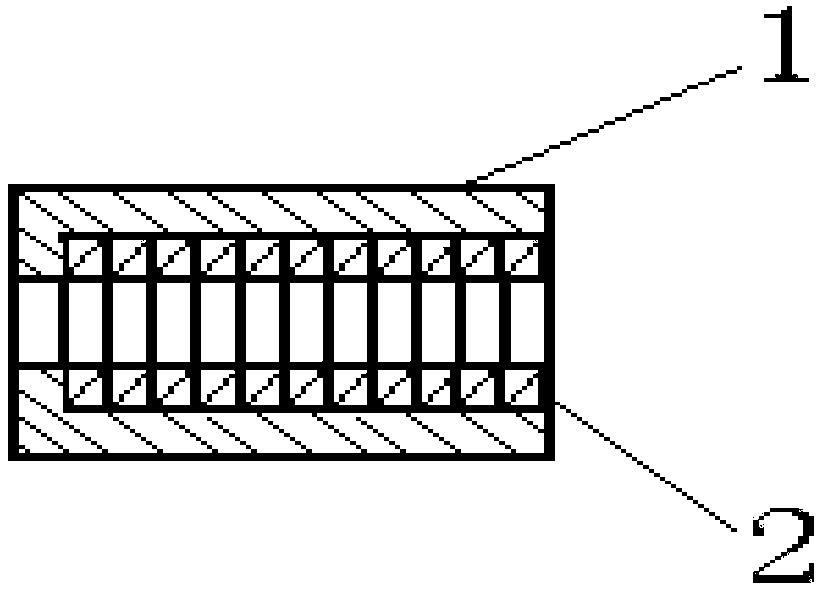

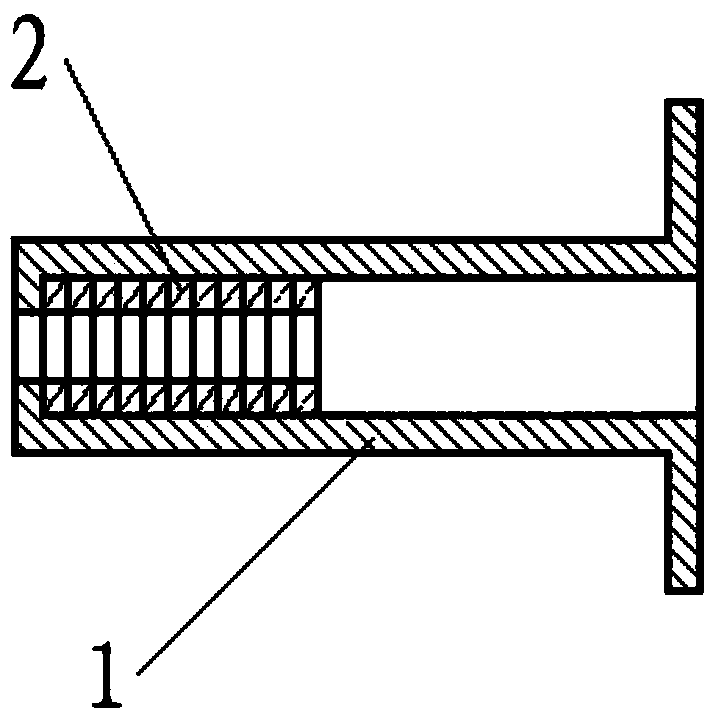

[0016] The utility model relates to a sleeve-combined spring sleeve assembled on a pull rod of a gap adjustment mechanism, which is used for automatic gap adjustment of aircraft wheels. The spring sleeve is composed of a sleeve 1 and a spring sleeve 2 . Sleeve 1 is a hollow rotating body, one end is open, and the other end has an end plate, which forms the shoulder of the spring sleeve, cooperates with the inner end surface of the spring sleeve 2, and is used to transmit and overcome the clamping of the spring sleeve during work. The action force of the force on the brake; the inner cavity of the sleeve 1 is used to accommodate the spring sleeve 2 assembled on the pull rod of the gap adjustment mechanism; the inner diameter of the sleeve 1 matches the outer diameter of the spring sleeve, and limits the outer diameter of the spring sleeve expansion, loosening, so as not to reduce the clamping force. The center of the shoulder of the sleeve 1 has a through hole matched with the...

Embodiment 2

[0026] The utility model relates to a sleeve-combined spring sleeve assembled on a pull rod of a gap adjustment mechanism, which is used for automatic gap adjustment of aircraft wheels. The spring sleeve is composed of a sleeve 1 and a spring sleeve 2 .

[0027] The composition of this embodiment, the matching requirements between the sleeve 1 and the spring sleeve 2 of this embodiment, and the materials are the same as those of the first embodiment.

[0028] The difference between this embodiment and Embodiment 1 is that the outer circumferential surface of the open end of the sleeve 1 has a radially protruding flange, which forms a fixed seat for the return spring in the wheel return mechanism that cooperates with it. , when this embodiment cooperates with the return force mechanism, the return force spring in the return force mechanism is set on the sleeve, and one end surface of the return force spring is against the end surface of the flange at the open end of the sleeve,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com