Light metal edge-wrapping structure for cornice and construction method thereof

A technology of metal edging and construction method, applied in building structure, roofing, construction, etc., can solve the problems of heavy cement cornice, single color and shape, easy to produce water seepage, etc., achieve weight reduction, wide application, avoid water seepage phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

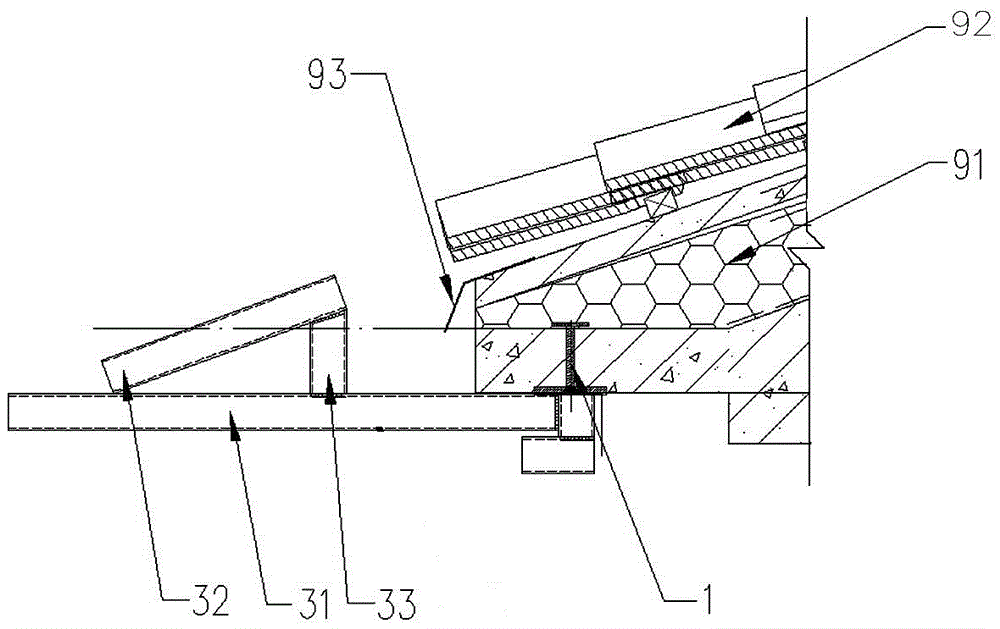

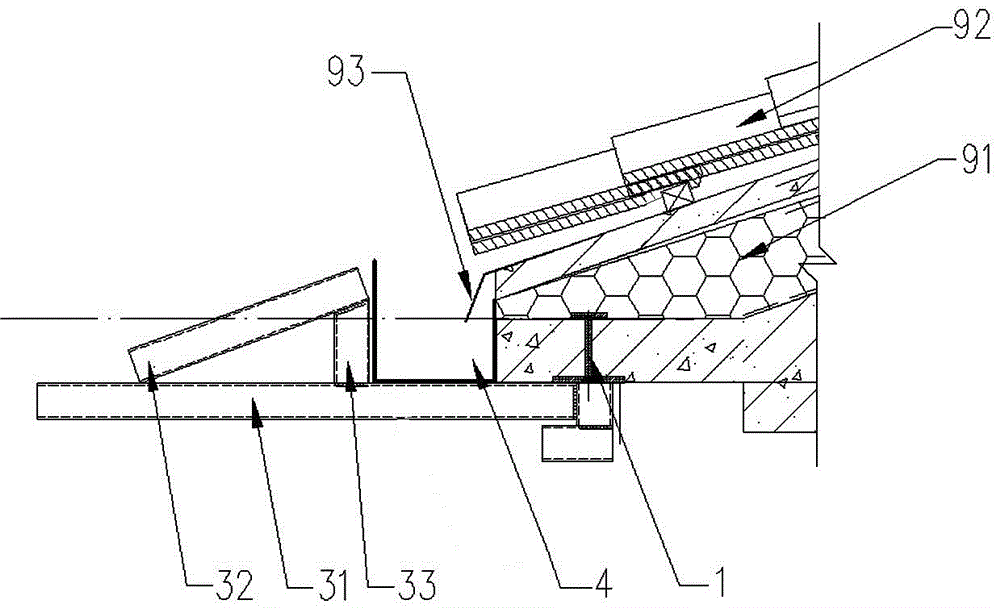

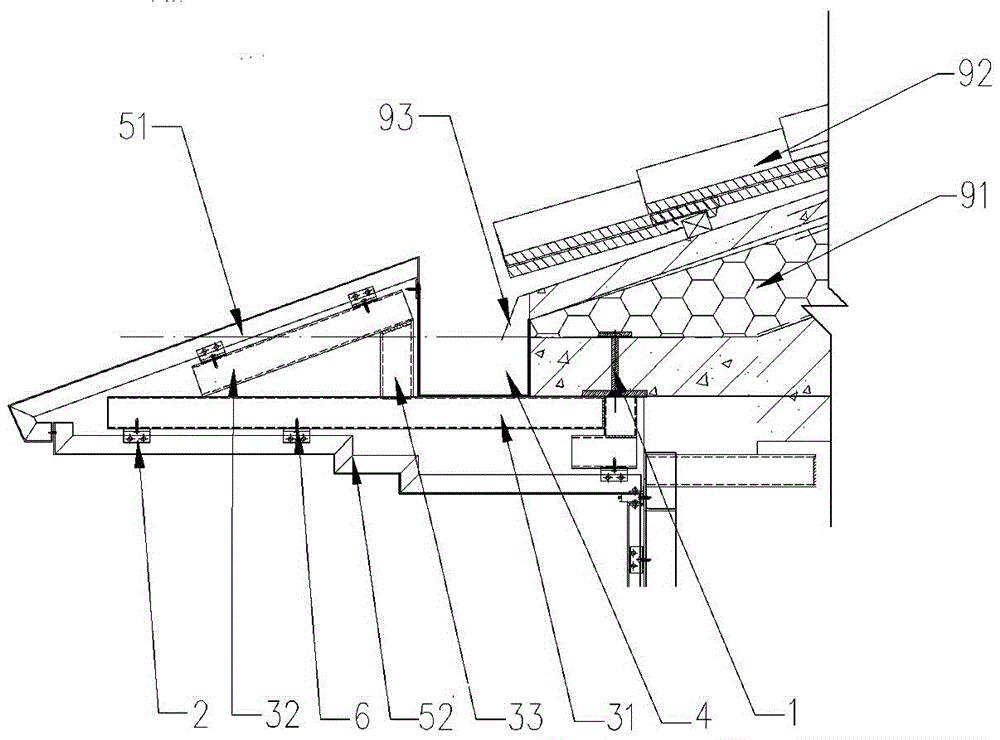

[0030] Such as figure 1 As shown, the light-weight metal edging structure of the eaves includes a keel and a gutter 4, and is characterized in that: the keel is horizontally suspended and fixed on the eaves 91, and a eaves 4 is provided between the eaves 91; the keels are Shape the keel, and the keel is equipped with edge-wrapping boards, and the edge-wrapping boards are made of light metal plates. The lightweight metal edging structure of the eaves involved in the embodiment of the present invention comprises keels, gutters 4 and edging boards, the keels include cantilevered keels 31, oblique keels 32 and vertical keels 33, the rear ends of the cantilevered keels 31 are connected to The cornice 91 is fixed, and the front section of the overhanging keel 31 is fixed with an oblique keel 32 and a vertical keel 33. The oblique keel 32, the vertical keel 33 and the front section of the overhanging keel 31 form a triangular keel skeleton; the triangular keel skeleton There is a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com