Connecting device for box-shaped section steel tube components

A connecting device and cross-section technology, which is applied in the direction of building structure and construction, can solve the problems of slow welding efficiency, inconvenient construction, unstable quality, etc., and achieve the effect of speeding up the splicing speed, easy connection operation, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

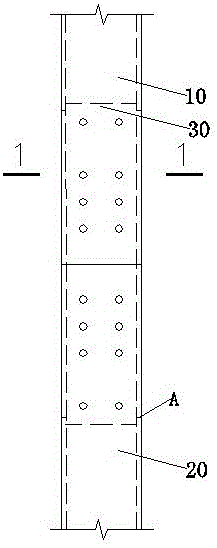

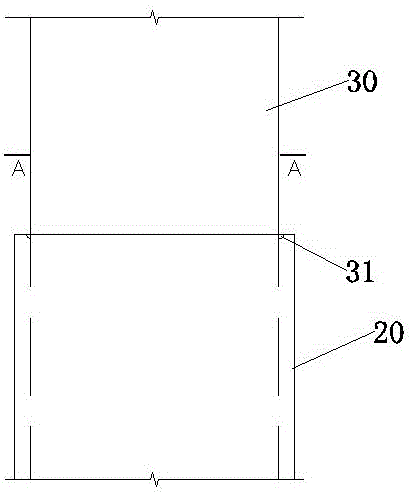

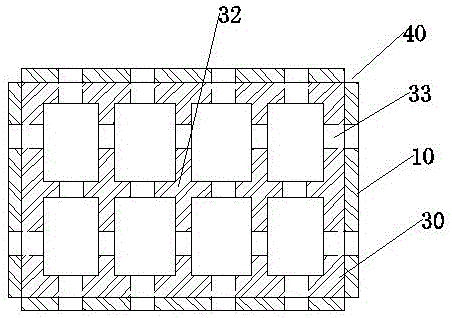

[0023] Such as figure 1 , 3 As shown, a connection device for a box-section steel pipe member includes an upper box-section steel pipe member 10, a lower box-section steel pipe member 20, an upper box-section steel pipe member 10 and a lower box-section steel pipe member 20 The connecting inner core 30 is placed inside the connecting inner core 30, and the width of the connecting inner core 30 is slightly smaller than the inner diameter of the box-section steel pipe member. The upper box-section steel pipe member 10 and the lower box-section steel pipe member 20 are respectively fixed to the connecting inner core 30 by bolts. The upper and lower ends of the connecting inner core 30 are respectively provided with threaded screw holes 33, and the upper box-shaped steel pipe member 10 and the lower box-shaped steel pipe member 20 are also provided with screw holes corresponding to the positions of the screw holes connecting the inner core 30. holes, can be fixed by long bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com