Preparation method for fermented tobacco blackberry extract flavor enhancement component

A fermentation type, blackberry technology, applied in the direction of tobacco, application, treatment of tobacco, etc., can solve problems such as application restrictions, and achieve the effects of low cost, soft smoke, and easy control of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

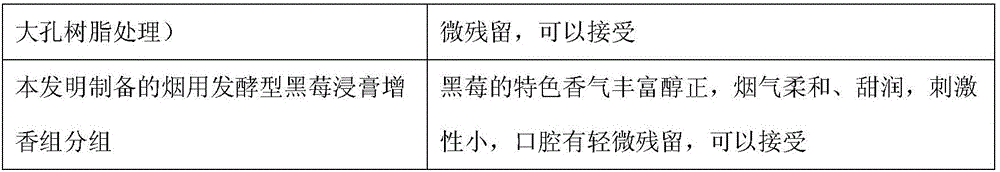

Examples

Embodiment 1

[0020] (1) adding sterile water to the acid-reduced yeast to prepare a 0.5% acid-reduced yeast solution by weight, for subsequent use;

[0021] (2) Fresh blackberries are cleaned, drained, and after beating, filter with gauze to obtain blackberry juice;

[0022] (3) Add the glucose of blackberry juice quality 2%% and the sodium chloride of 0.3%% in the blackberry juice, and inoculate the acid-reducing yeast solution described in step 1 of blackberry juice quality 0.5%%, be 50rpm at stirring speed, ventilate The amount is 1wm, and the fermentation temperature is 20°C and fermented for 5 days to obtain a fermented liquid;

[0023] (4) After filtering the fermented liquid obtained in step (2), take the clarified liquid, add 4 times the weight of 95% ethanol to carry out alcohol precipitation treatment, filter, concentrate to a relative density of 1.20, and obtain fermented blackberry extract;

[0024] (5) Add its activated macroporous resin of 4 times the weight and ultrapure wa...

Embodiment 2

[0028] (1) adding sterile water to the acid-reduced yeast to prepare a 1.0% acid-reduced yeast solution for subsequent use;

[0029] (2) Fresh blackberries are cleaned, drained, and after beating, filter with gauze to obtain blackberry juice;

[0030] (3) Add 3.5% glucose and 0.6% sodium chloride of blackberry juice quality in the blackberry juice, and inoculate 1.5% of the acid-reducing yeast solution described in step 1, and the stirring speed is 80rpm, and the ventilation is 0.7wm, and ferment Fermentation at 20°C for 8 days;

[0031] (4) Filtrate the fermented liquid obtained after fermentation, take the clarified liquid, add 5 times the weight of 95% ethanol to carry out alcohol precipitation treatment, filter, concentrate to a relative density of 1.35, and obtain fermented blackberry extract;

[0032] (5) Add 5 times the weight of activated macroporous resin and 20 times the weight of ultrapure water to the blackberry extract, fully stir for 30 minutes, settle naturally...

Embodiment 3

[0036] (1) adding sterile water to the acid-reduced yeast to prepare a 0.7% acid-reduced yeast solution for subsequent use;

[0037] (2) Fresh blackberries are cleaned, drained, and after beating, filter with gauze to obtain blackberry juice;

[0038] (3) Add the glucose of blackberry juice quality 2.0% and the sodium chloride of 0.4% in the blackberry juice, and inoculate the yeast solution described in step 1 of 0.5%, be 100rpm in stirring speed, ventilation is 0.5wm, fermentation temperature is Ferment at 23°C for 10 days;

[0039] (4) Filtrate the fermented liquid obtained after fermentation, take the clarified liquid, add 3 times the weight of 95% ethanol to carry out alcohol precipitation treatment, filter, concentrate to a relative density of 1.24, and obtain fermented blackberry extract;

[0040] (5) Add 3 times the weight of activated macroporous resin and 15 times the weight of ultrapure water to the blackberry extract, fully stir for 30 minutes, settle naturally fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com