A kind of alcohol ether borate type brake fluid

A technology of alcohol ether borate ester and brake fluid, which is applied in lubricating compositions, petroleum industry, etc. It can solve the problems of poor water capacity, borate esters are sensitive to water, and easy to precipitate sediments, etc., and achieve high temperature resistance to air resistance Strong resistance, excellent physical and chemical properties, good low temperature fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

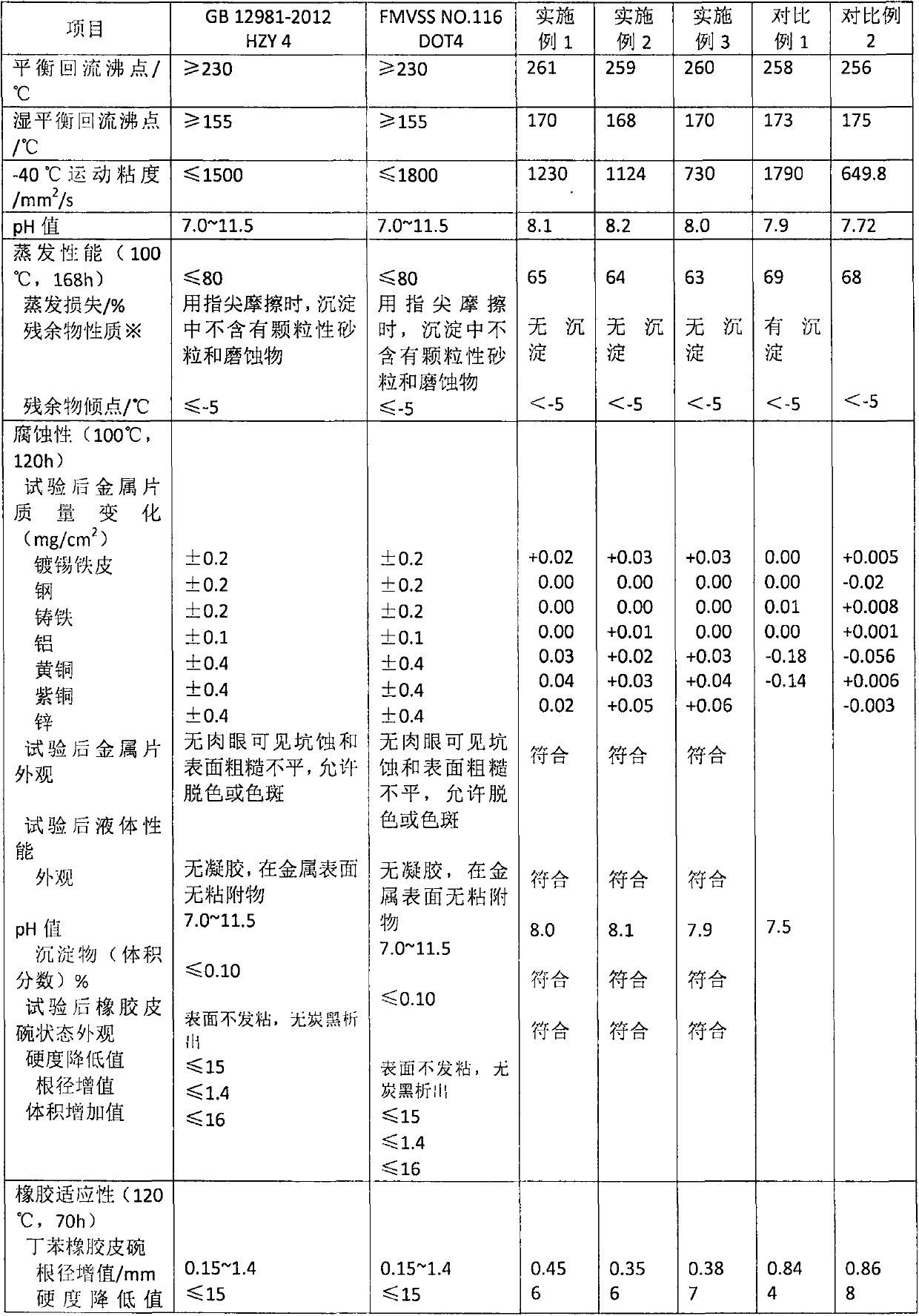

Examples

Embodiment 1

[0026] at 1.2m 3 In the reconciling kettle, add 360 kilograms of triethylene glycol monomethyl ether borate, 250 kilograms of polyethylene glycol monobutyl ether borate, 200 kilograms of triethylene glycol monomethyl ether, 180 kilograms of diethylene glycol, antioxidant Agent T501 2 kg, methyl benzotriazole 1 kg, butylamine ether 7 kg. Add the above raw materials into the reaction kettle in turn, and stir for 30 minutes at 30°C. After the raw materials are fully dissolved, filter them into the finished product tank.

Embodiment 2

[0028] at 1.2m 3 Add 400 kilograms of triethylene glycol monomethyl ether borate, 200 kilograms of polyethylene glycol monobutyl ether borate, 150 kilograms of triethylene glycol monoethyl ether, and 60 kilograms of triethylene glycol dimethyl ether in the blending kettle. , 180 kg of triethylene glycol, 12 kg of antioxidant T50, 2 kg of benzotriazole, and 6 kg of methamphetamine. Add the above-mentioned raw materials into the reaction kettle in turn, and stir for 60 minutes at 50°C. After the raw materials are fully dissolved, filter them into the finished product tank.

Embodiment 3

[0030] at 1.2m 3 Add 430 kilograms of triethylene glycol monomethyl ether borate, 120 kilograms of polyethylene glycol monobutyl ether borate, 200 kilograms of triethylene glycol monomethyl ether, and 80 kilograms of triethylene glycol dimethyl ether in the blending kettle. kg, 160 kg of PEG-188, 2 kg of bisphenol A, 1 kg of benzotriazole, and 7 kg of butylamine ether. Add the above raw materials into the reaction kettle in turn, stir at 80°C and normal pressure for 120min, after the raw materials are fully dissolved, filter them into the finished product tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com