G75 electronic yarn impregnating compound and preparation method thereof

A technology of sizing agent and electronic yarn, applied in the field of electronic spun yarn, can solve the problems of reducing hairiness, unsatisfactory antistatic effect, poor tensile strength, etc., and achieve the effect of reducing hairiness, good antistatic effect and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

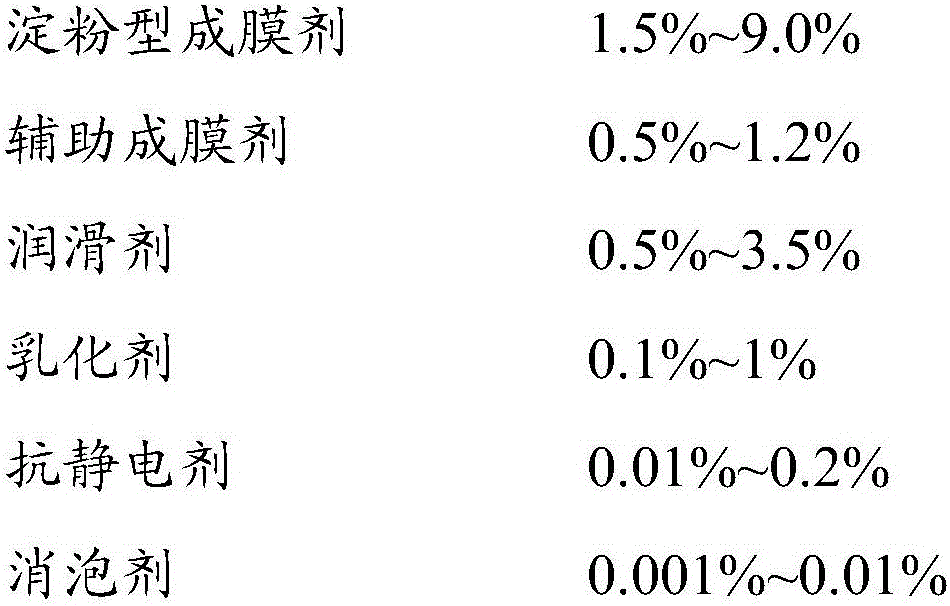

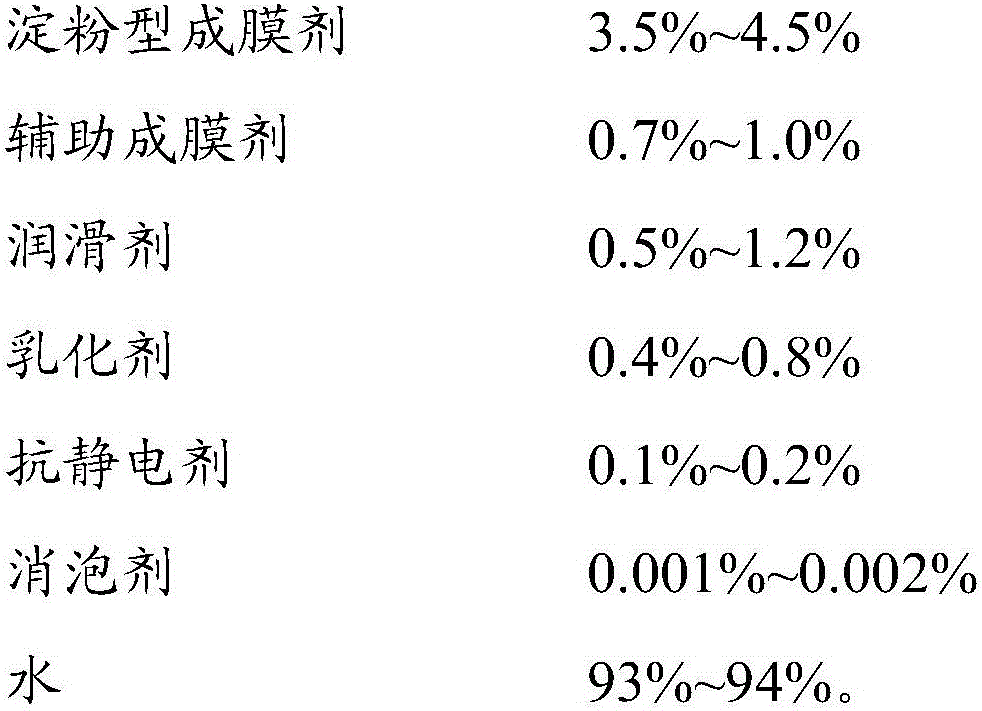

[0037] Three kinds of G75 electronic yarn sizing agents in this embodiment, by weight percentage, respectively include the raw materials shown in Table 1:

[0038] Table 1

[0039] components

Example

Example 2

Example 3

Etherified High Amylose Starch

2.34%

2.57%

3.00%

Esterified cross-linked starch

1.17%

1.50%

0.75%

Waterborne epoxy resin

0.80%

0.80%

0.85%

Emulsifier

0.75%

0.47%

0.56%

0.45%

0.31%

0.35%

0.43%

0.27%

0.32%

0.15%

0.15%

0.15%

0.0062%

0.0072%

0.0066%

0.001%

0.001%

0.001%

Deionized water

margin

margin

margin

[0040] The preparation method of the above-mentioned G75 electronic yarn sizing agent comprises the following steps:

[0041] (1) emulsifying the hydrogenated vegetable oil and microcrystall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com