A method for unloading a cartoning machine

A cartoning machine and unboxing technology, which is applied in the directions of packaging, conveyors, and object destacking, etc. It can solve the problems that the trays cannot be separated accurately, the fork plate cannot be inserted accurately, etc., and it is easy to deform and shrink. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for unloading a cartoning machine comprises the steps:

[0031] A. Place multiple stacked trays in the tray storage space 5;

[0032] B. The front, rear, left and right four sides of the tray storage space 5 are each provided with at least one fork plate 3, and the two fork plates 3 provided in the front and rear directions are the first group of fork plates 6. The two fork plates 3 provided are the second group of fork plates 7, and the second group of fork plates 7 are located under the lowermost tray, supporting a plurality of stacked trays. Support the tray;

[0033] C. The negative pressure device 8 positioned below the plurality of trays rises below the outer bottom surface of the lowermost tray, and implements negative pressure adsorption on the bottom surface of the tray;

[0034] D. The negative pressure device 8 continues to carry out negative pressure adsorption on the outer bottom surface of the tray. After the negative pressure device 8 moves dow...

Embodiment 2

[0039] A method for unloading a cartoning machine comprises the steps:

[0040] A. Place multiple stacked trays in the tray storage space 5;

[0041] B. The front, rear, left and right four sides of the tray storage space 5 are each provided with at least one fork plate 3, and the two fork plates 3 provided in the front and rear directions are the first group of fork plates 6. The two fork plates 3 provided are the second group of fork plates 7, and the second group of fork plates 7 are located under the lowermost tray, supporting a plurality of stacked trays. Support the tray;

[0042] C. The negative pressure device 8 positioned below the plurality of trays rises below the outer bottom surface of the lowermost tray, and implements negative pressure adsorption on the bottom surface of the tray;

[0043] D. The negative pressure device 8 continues to carry out negative pressure adsorption on the outer bottom surface of the tray. After the negative pressure device 8 moves dow...

Embodiment 3

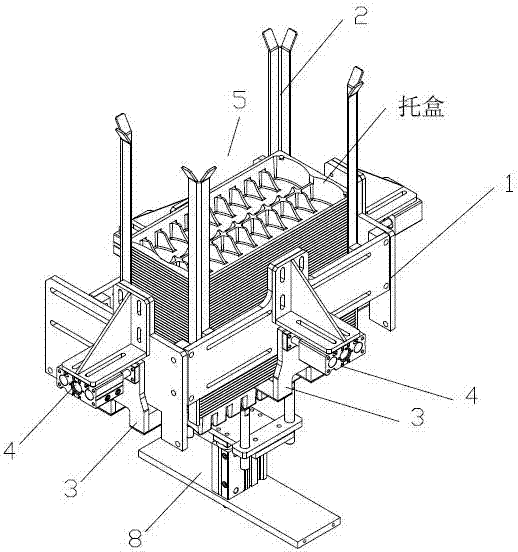

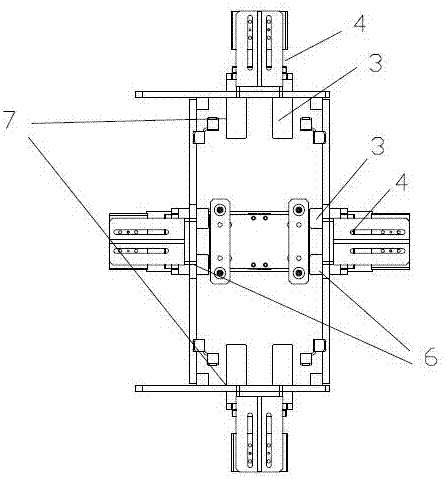

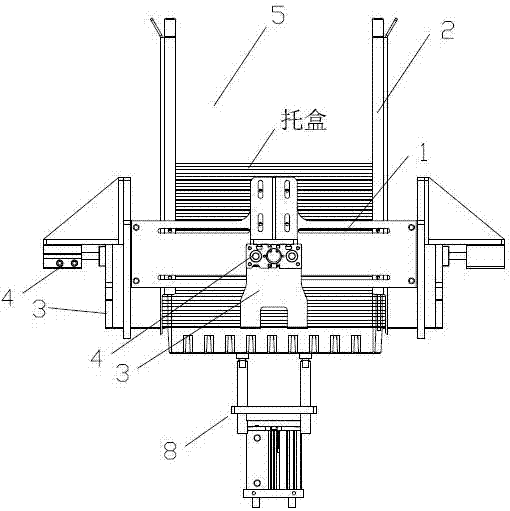

[0050] The equipment for realizing the method of embodiment 1 and embodiment 2 is the lower box mechanism of the product cartoning machine, which includes a fixed frame 1, and a plurality of guard plates 2 for fixing the positions of the trays are installed in the fixed frame 1. A fork plate 3 is arranged between adjacent guard plates 2, the fork plate 3 is connected to the fork plate cylinder 4, a negative pressure device 8 is arranged under the guard plate 2, and the guard plate 2 surrounds to form a tray for placing a tray Storage space 5, at least one fork plate 3 is provided in each of the front, rear, left and right directions of the tray storage space 5, and the two fork plates 3 provided in the front and rear directions are the first set of fork plates 6. The two fork plates 3 arranged in the left and right directions are the second set of fork plates 7, and the first set of fork plates 6 and the second set of fork plates 7 alternately perform horizontal reciprocating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com