An adjustable mobile cloth device

A moving cloth and adjustable technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of backward alignment process, prone to wrong root cloth, messy, etc., to achieve high conveying efficiency, stable blanking, The effect of neat arrangement of bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

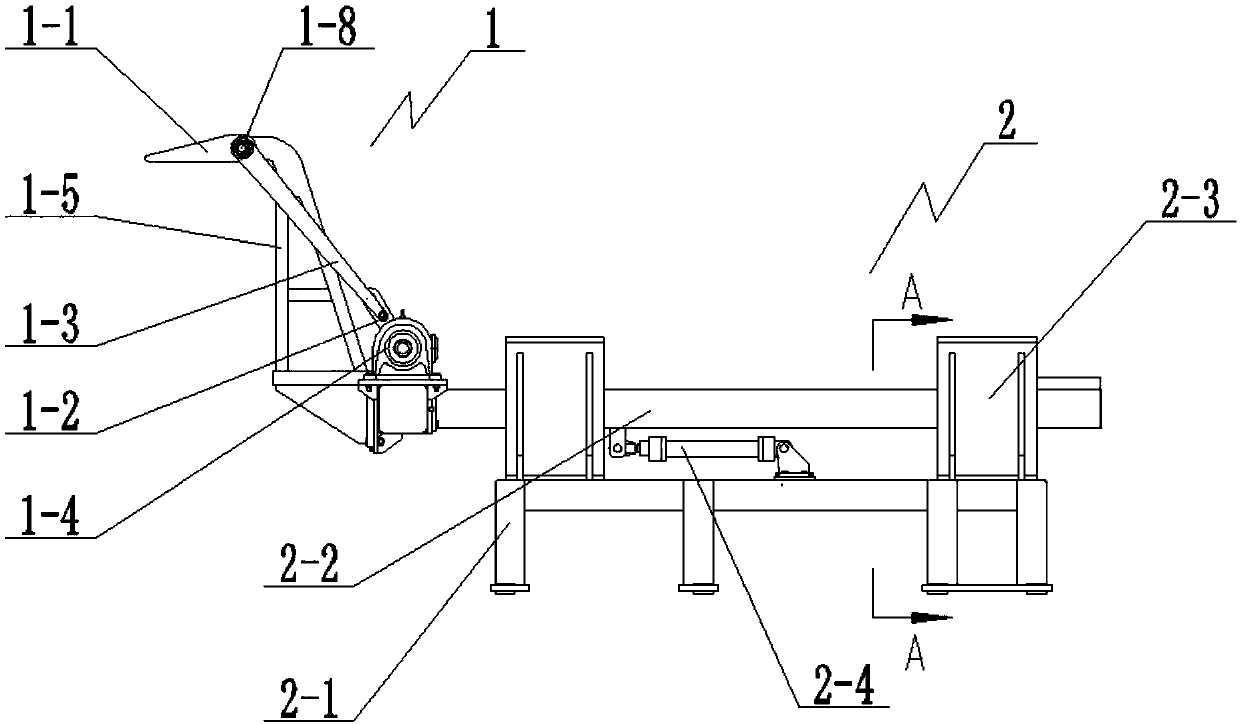

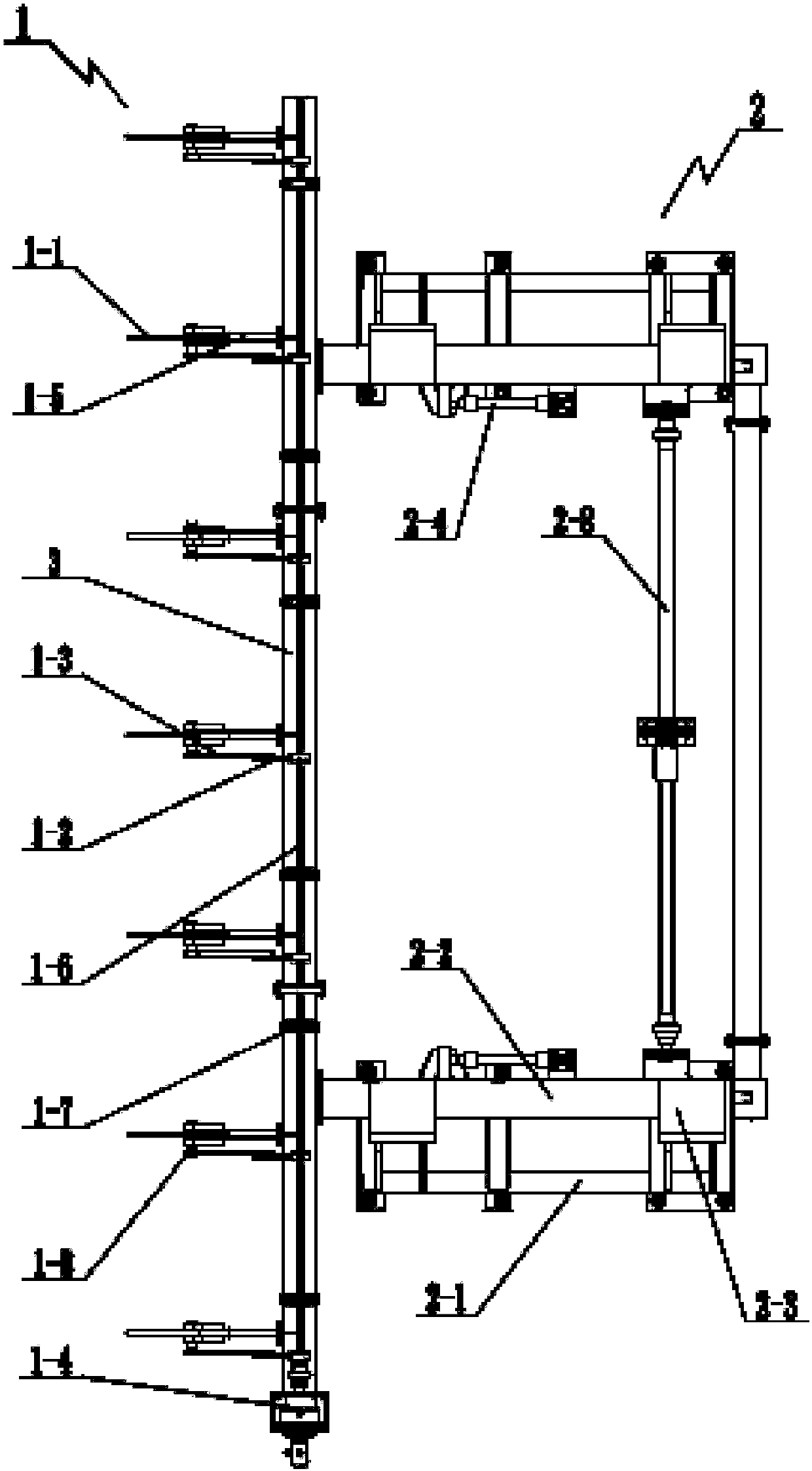

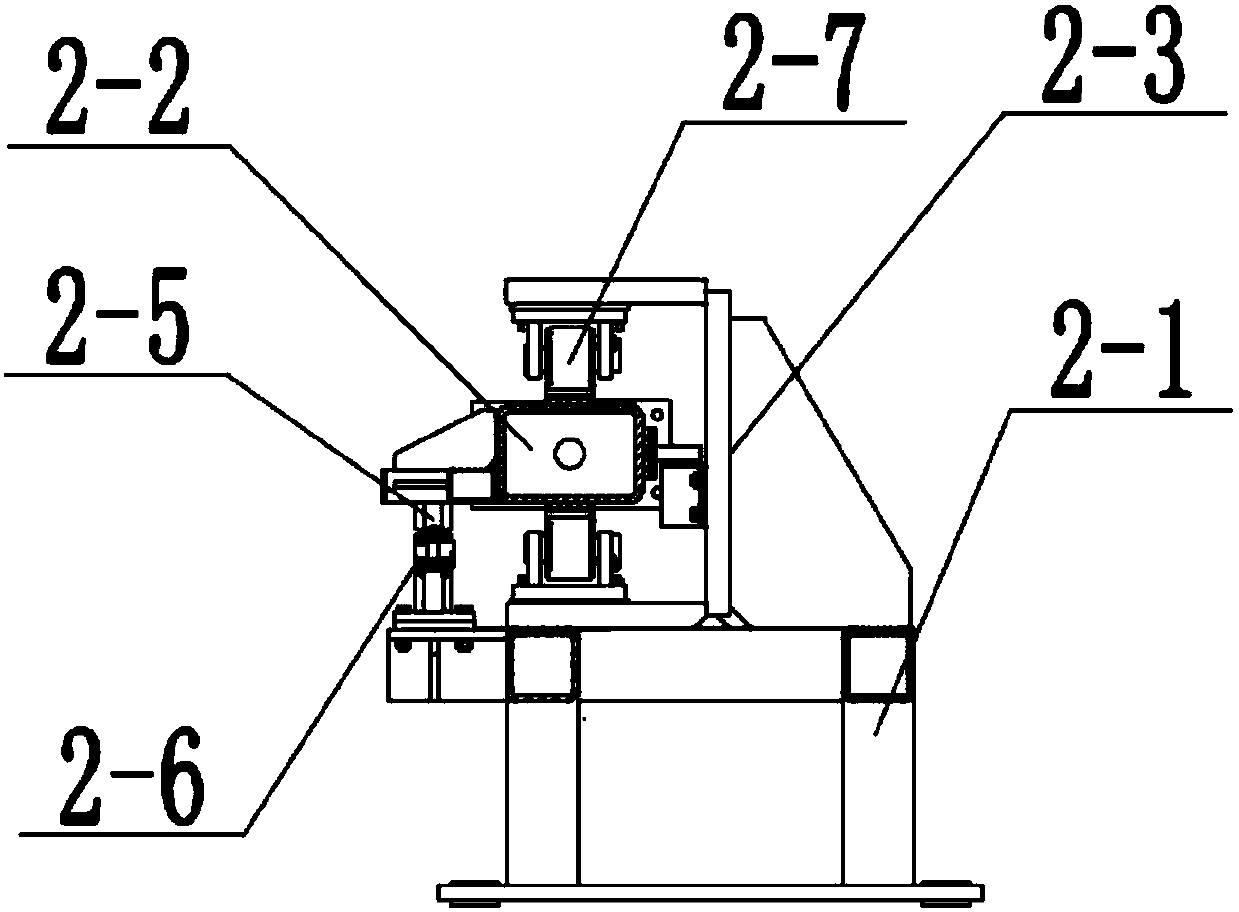

[0014] Such as Figure 1 to Figure 3 As shown, an adjustable mobile distributing device in this embodiment includes a reciprocating movement system and a crossbeam 3, wherein: it also includes a blanking angle adjustment system, and the blanking angle adjustment system is composed of several blanking adjustment devices 1. The transmission device 1-4, the rotating shaft 1-6 and the bearing seat 1-7 are composed. The several blanking adjustment devices 1 are arranged on the front end of the beam 3, and each blanking adjustment device 1 includes a moving tongue 1-1 , a crank 1-2, a swing rod 1-3, a rotary shaft 1-8 and a blanking adjustment bracket 1-5, the blanking adjustment bracket 1-5 is installed on the front end of the beam 3, and the rotary shaft 1-8 is hinged on the falling The upper end of material adjustment bracket 1-5 can rotate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com