Ship hydrostatic force performance experimental device and method

An experimental device and hydrostatic technology, applied in ship parts, ship construction, ship design, etc., can solve the problems of high requirements for ship inspection, long time spent, complicated operation, etc., to improve the speed of the experiment, simple operation, The effect of ensuring the accuracy of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

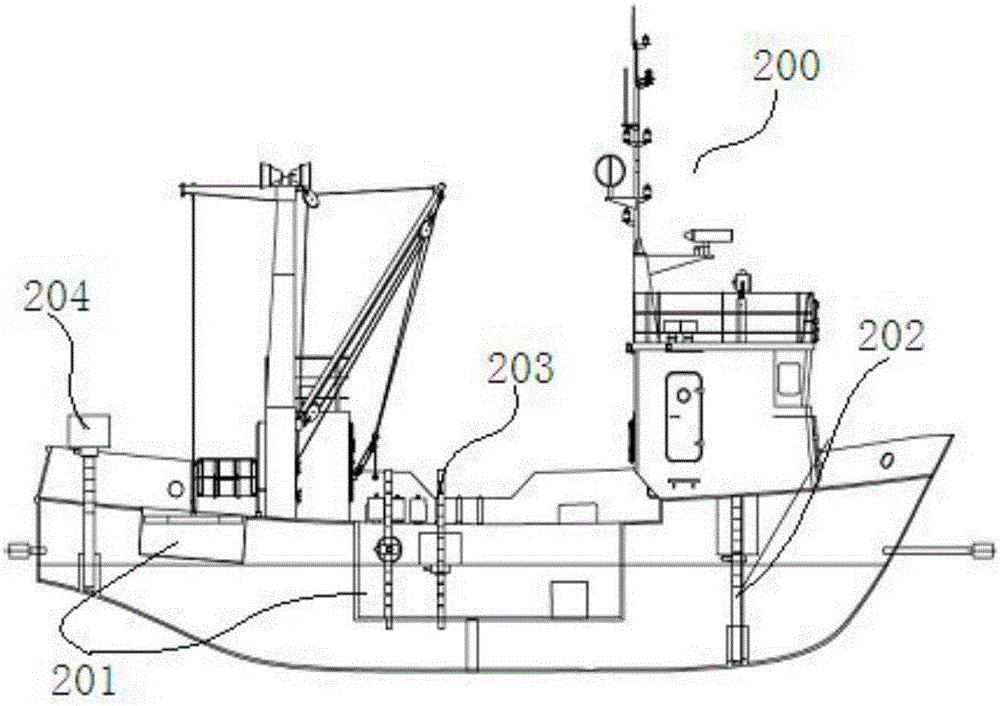

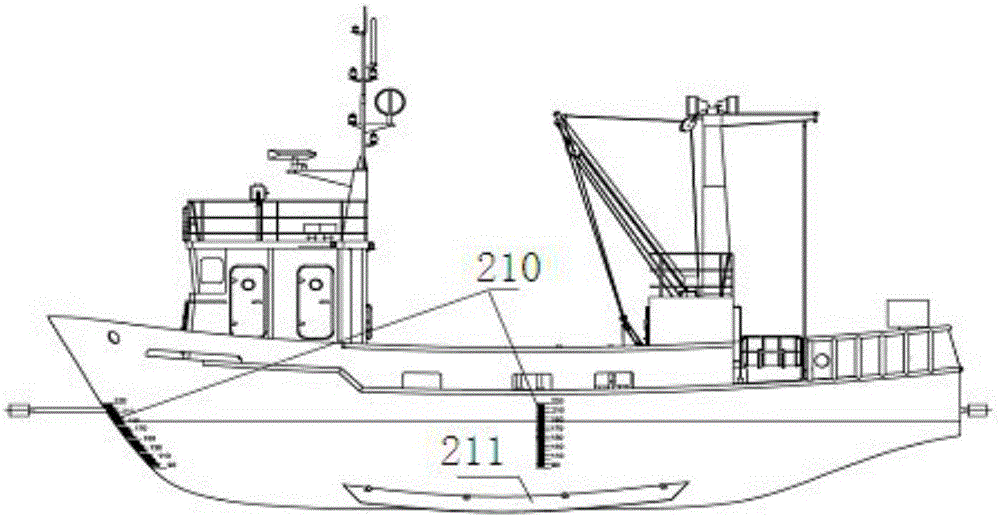

[0029] Such as Figure 5 As shown, a ship hydrostatic performance experiment device of the present invention includes a water tank 100 , a hull model 200 and a heeling moment measuring device 300 . Wherein the hull model 200 is freely placed in the water tank 100, the heeling moment measuring device 300 is arranged on the side of the water tank 100 close to the bow, and the moment central axis of the heeling moment device 300 is connected with the hull of the hull model 200.

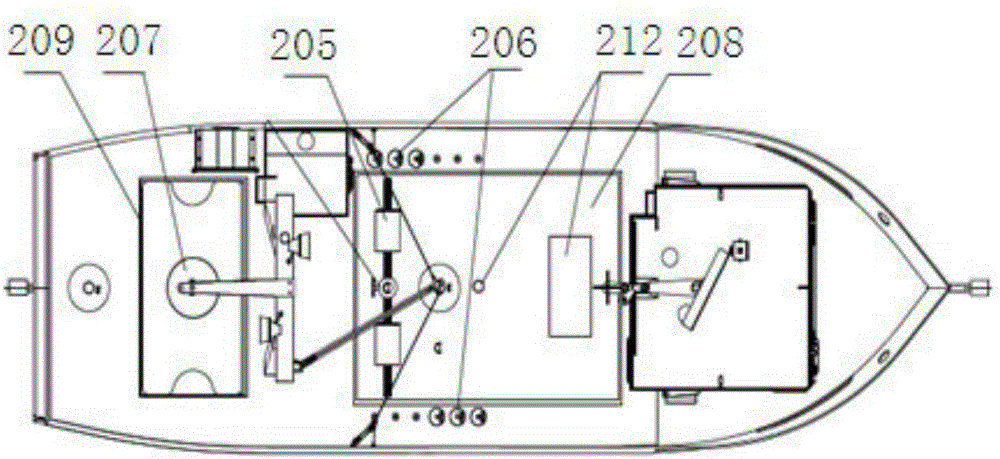

[0030] Such as image 3 As shown, the hull model 200 of the present invention includes a ballast system 201, a weight system, a bow weight 202, a midship weight 203 and a stern weight 204, an adjustable weight 205, a deck weight 206, a suspension 207, a cargo warehouse 208, and a deck warehouse 209 , draft marking line 210 , detachable bilge keel 211 and sensor 212 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com