Large-scale rotary drilling machine

A rotary drilling rig, large-scale technology, used in motor vehicles, crawler vehicles, transportation and packaging, etc., can solve problems such as insufficient stability and increased width, and achieve simple and convenient position adjustment, weight reduction, and reduction of grounding specific pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be explained in detail below in conjunction with examples.

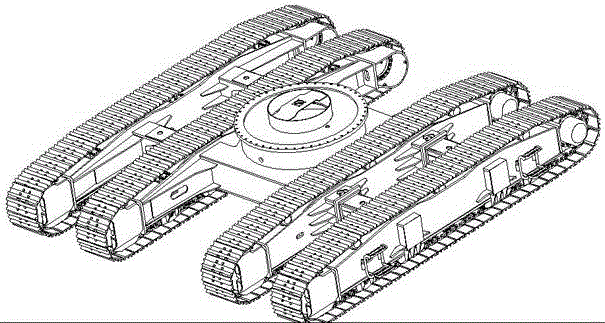

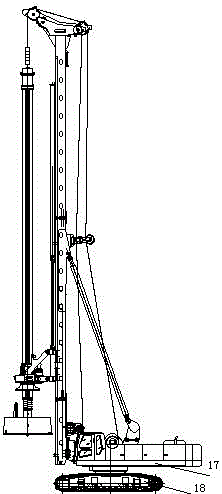

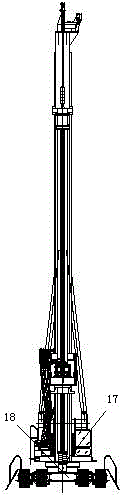

[0020] Such as figure 1 with figure 2 As shown, the present invention is basically the same as the prior art, that is, a rotary platform assembly is arranged on the chassis, and a rotary drilling rig assembly is arranged on the rotary platform assembly. Depend on image 3 It can be seen that the chassis of the present invention is also similar to the chassis of the 201510929021.6 patent, and track beams 1 are also arranged on both sides of the vehicle frame, and the track beam 1 has an H-shaped structure as a whole. But the present invention is different from the prior art in that: the cross-section of its crawler beam is a rectangular hollow box beam, see attached Figure 8 , the outstretched end of crawler beam 1 is provided with the parts that crawler belt is installed, can install crawler belt by this part, simultaneously in the present invention has added the hollow box type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com