Non-excavation type reforming method of oil tank

A non-excavation and oil tank technology, applied in the direction of chemical instruments and methods, containers, packaging items, etc., can solve problems such as a large number of air bubbles, increased personal and environmental safety problems, and adverse health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a method for non-excavation transformation of oil tanks, which can mainly carry out non-excavation transformation of buried oil tanks. The method mainly includes: figure 1 The flow shown:

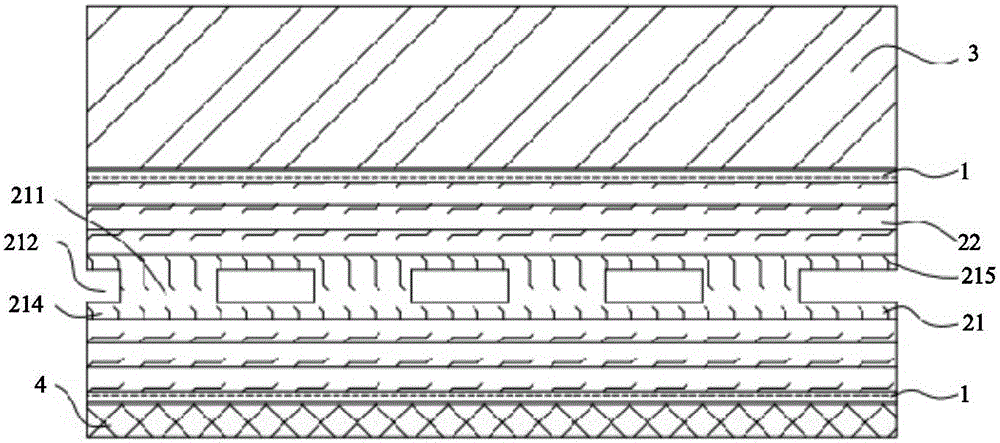

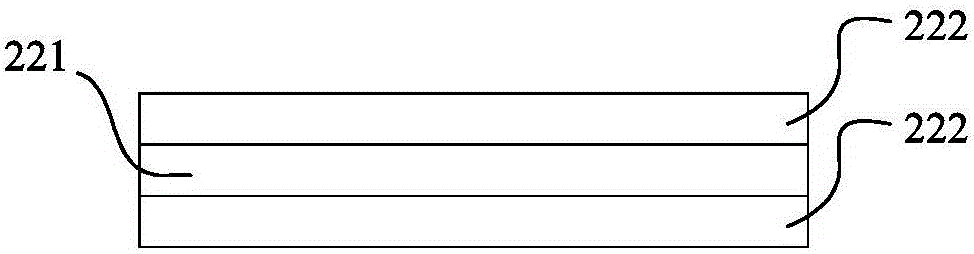

[0074] 101, in the form of a detachable prefabricated part, the composite reinforcement layer 2 is covered on the inner surface of the oil tank body 3 through the adhesive layer 1. The composite reinforcement layer 2 includes: the skeleton penetrating layer 21, and the skeleton penetrating layer 21 The glass fiber reinforced layer 22 on the top, the frame penetration layer 21 includes: a frame 211 and a through cavity 212 between the frames 211 for placing oil and gas leakage detection components, a panel 214 and a bottom plate 215, the panel 214 is located on one side of the frame 211 side, the bottom plate 215 is located on the other side of the skeleton, such as figure 2 The trenchless transformation structure of the oil tank is shown.

[0075] Specific...

Embodiment 2

[0103] The difference between this embodiment and the foregoing embodiment mainly lies in:

[0104] Step 101 of this embodiment specifically includes:

[0105] In the form of a small-sized releasable prefabricated sheet 300, the side of the first releasable prefabricated sheet constituting the glass fiber reinforced layer 22 that is not covered with the first release member is covered on the tank through the prefabricated adhesive layer 1 On the inner surface of the body 3, after separating the first release part, the side of the second release prefabricated sheet constituting the skeleton penetration layer 21 that is not covered with the second release part is passed through in the form of a small-sized releasable prefabricated sheet The prefabricated adhesive layer 1 is covered on the other side of the glass fiber reinforced layer 22, or, the second releasable prefabricated sheet constituting the skeleton penetrating layer 21 is formed in the form of a small-sized releasable...

Embodiment 3

[0108] The difference between this embodiment and the foregoing embodiment mainly lies in:

[0109] The composite reinforcement layer 2 also includes: a grid cloth reinforcement layer 23 covered on the inner surface of the tank body 3 through the prefabricated adhesive layer 1 in the form of a detachable prefabricated part, and the mesh cloth reinforcement layer 23 is passed through the prefabricated adhesive layer. 1 Bonded with the glass fiber reinforced layer 22 or the skeleton penetrating layer 21, such as Figure 12 shown.

[0110] Then, the corresponding step 101 specifically includes:

[0111] In the form of a small-sized releasable prefabricated sheet 300, the side of the third releasable prefabricated sheet that constitutes the grid cloth reinforcement layer 23 that is not covered with the third release member is covered by a prefabricated adhesive layer 1 on the On the inner surface of the tank body 3, after the third release part is separated, the uncoated first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com