Horizontal loading and taking robot and operating method thereof

A robot and horizontal technology, applied to other household appliances, household components, household appliances, etc., to achieve the effects of high work efficiency, reduced production costs, and high coordination accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

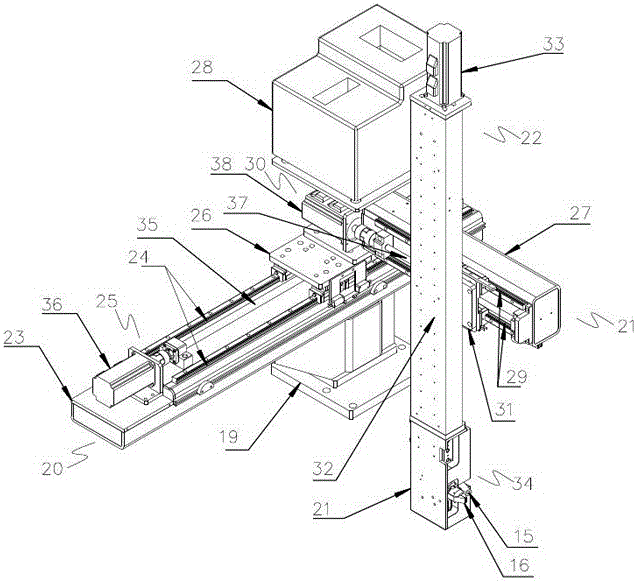

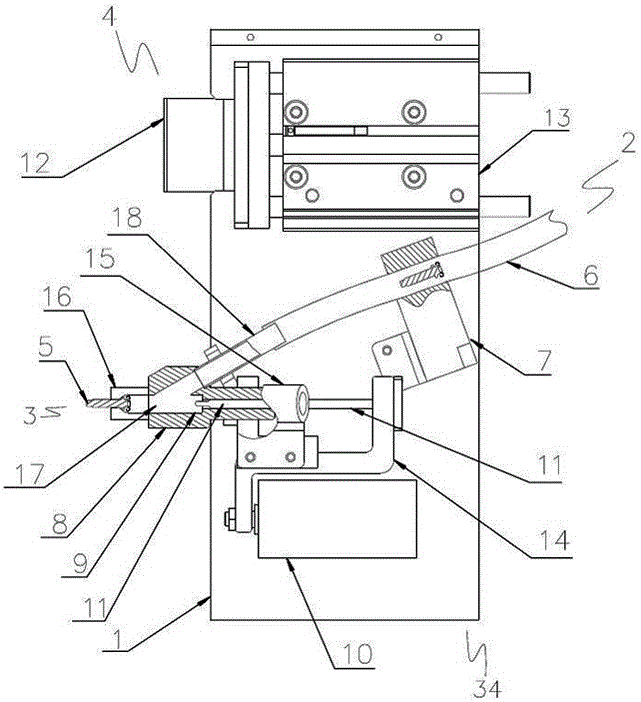

[0029] A kind of horizontal charging and taking robot described in this embodiment 1, such as figure 1 with figure 2 As shown, it includes a machine base 19, an X-axis mechanism 20 fixedly installed on the machine base, a Y-axis mechanism 21 slidably connected with the X-axis mechanism, and a Z-axis mechanism 22 slidably connected with the Y-axis mechanism. The X-axis mechanism includes a fixed The X-axis main body 23 installed on the machine base, the X-axis slide rail 24 fixed on the X-axis main body and slidingly connected with the Y-axis mechanism, and the X-axis drive that drives the Y-axis mechanism to slide back and forth on the X-axis slide rail Device 25, the Y-axis mechanism includes a Y-axis slide seat 26 that is slidably connected with the X-axis slide rail, a Y-axis main body 27 that is fixedly connected with the Y-axis slide seat, a spike sorter 28 installed on the Y-axis main body, a fixed The Y-axis slide rail 29 which is arranged on the main body of the Y-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com