Cooling and Inner Wall Lubricating Device of Magnesium Alloy Continuous Casting Liquid-Solid Converter

A liquid-solid converter and lubricating device technology is applied in the field of cooling and inner wall lubrication of magnesium alloy continuous casting liquid-solid converters, which can solve the problems that restrict the popularization process of magnesium alloys, slow billet drawing, and affect the rapid production of magnesium alloy billets. and other problems to achieve the effect of improving the shelling effect, reducing friction and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

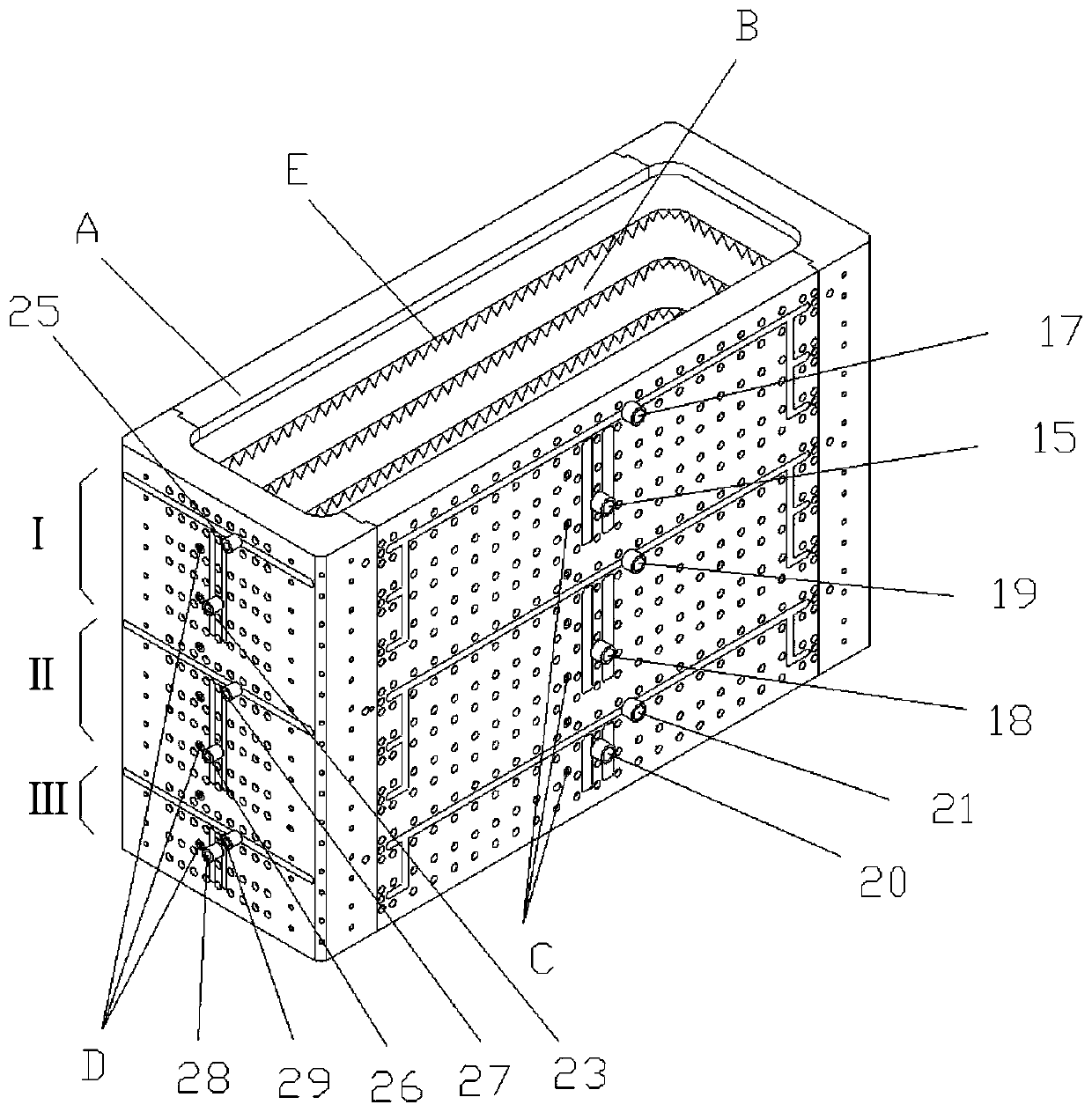

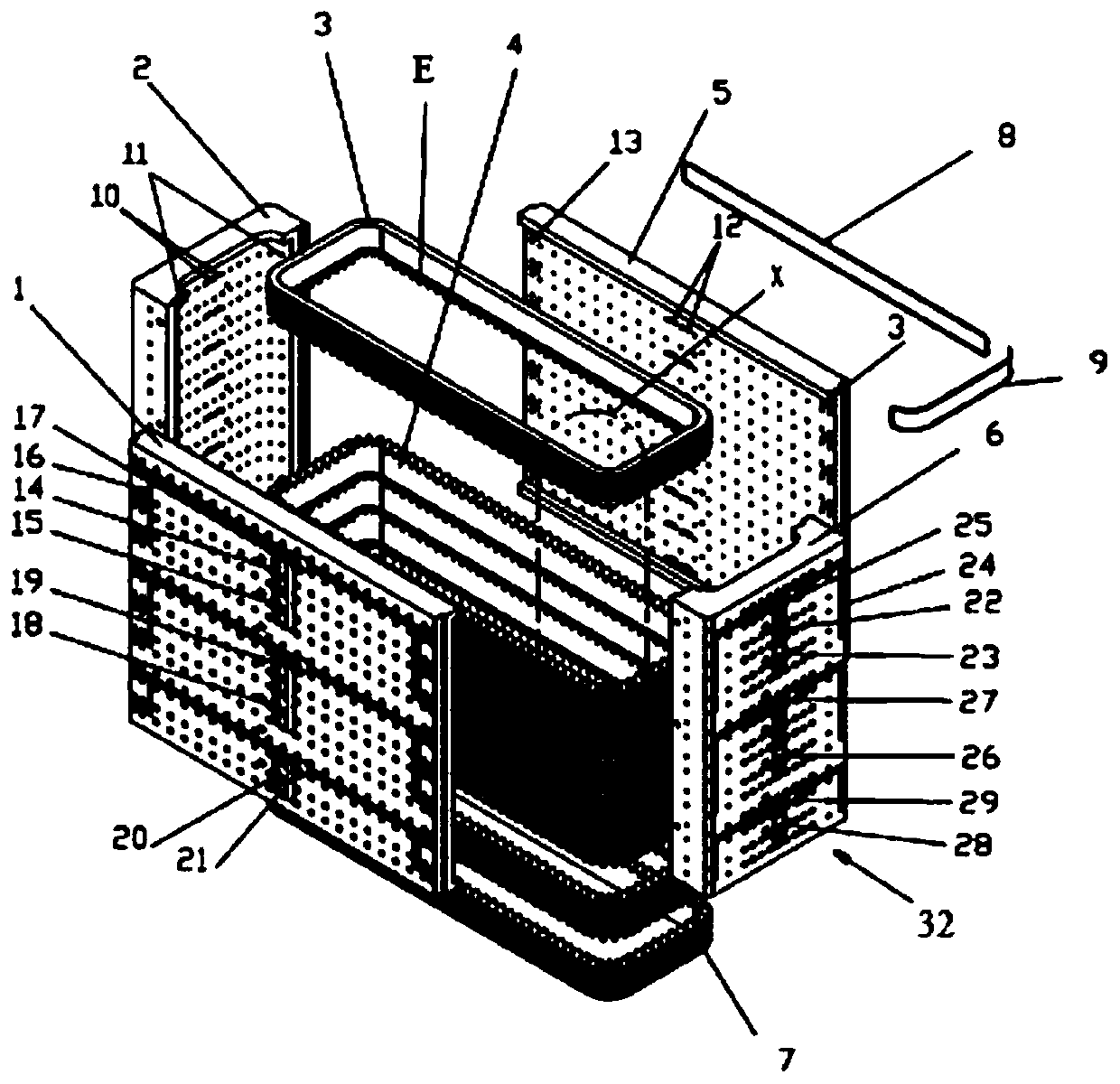

[0027] see figure 1 , the cooling and inner wall lubricating device of the magnesium alloy continuous casting liquid-solid converter provided by the present invention includes an inner wall B composed of multi-layer curves, and the back plate A and the inner wall B cooperate to form a joint surface that can pass into cooling water; combined The surface is divided into several cooling areas from top to bottom, and each cooling area has an independent water inlet and outlet;

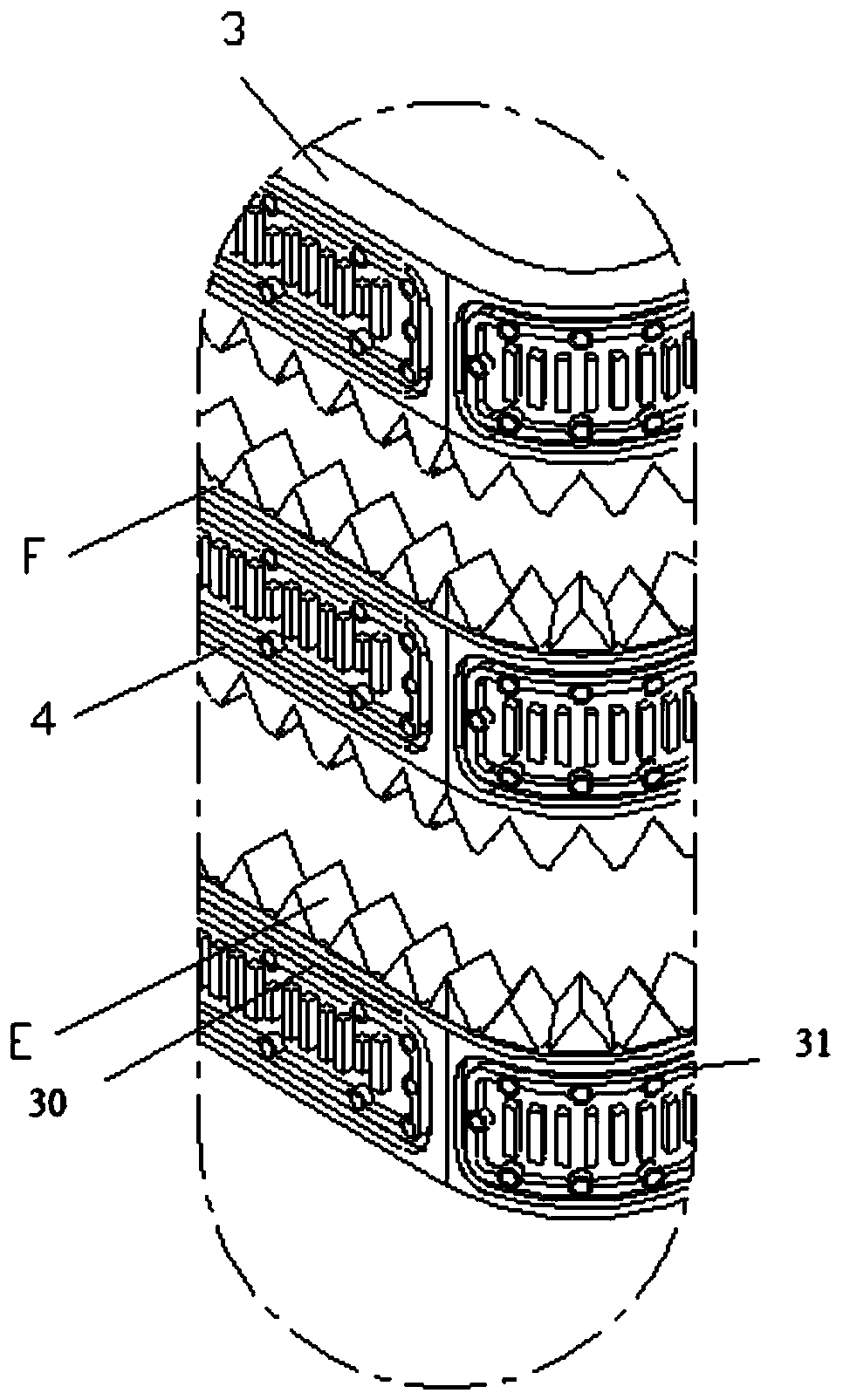

[0028] There is a gap between the spliced surface E formed by the splicing of curves on the inner wall B, and the gap communicates with the lubricating oil through hole C opened on the back plate A, providing a lubricating channel for the area between the solidified magnesium alloy shell and the inner wall B.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com