Tubular fixed-bed reactor for selective co-hydrogenation of mixed C4 containing high-concentration alkyne and alkadiene

A technology of fixed bed reactor and mixed carbon four, which is applied in the fields of hydrogenation hydrocarbon production, chemical instruments and methods, organic chemistry, etc., can solve the problems of low conversion rate, large equipment volume, coking of reactor, etc., and achieve high conversion rate, The effect of flexible operation and increased airspeed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

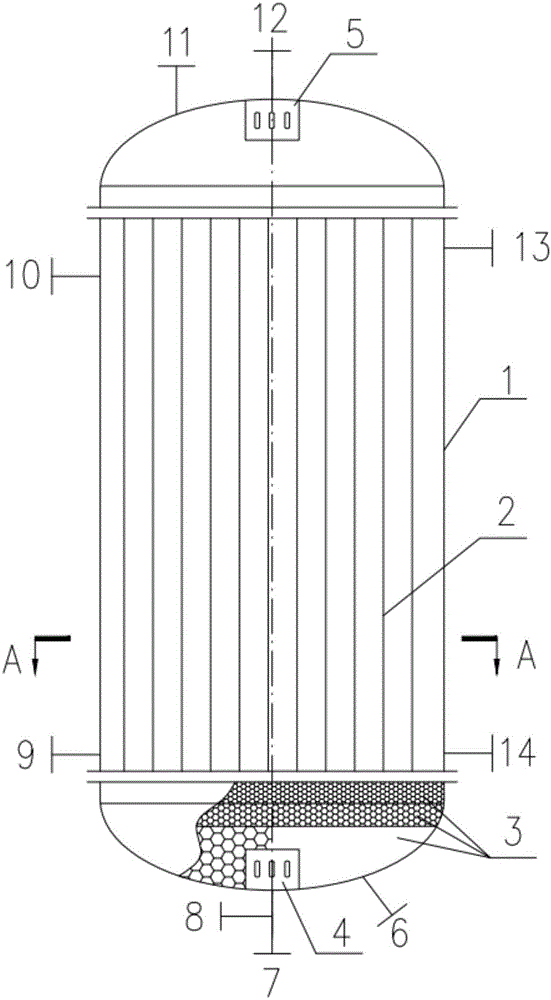

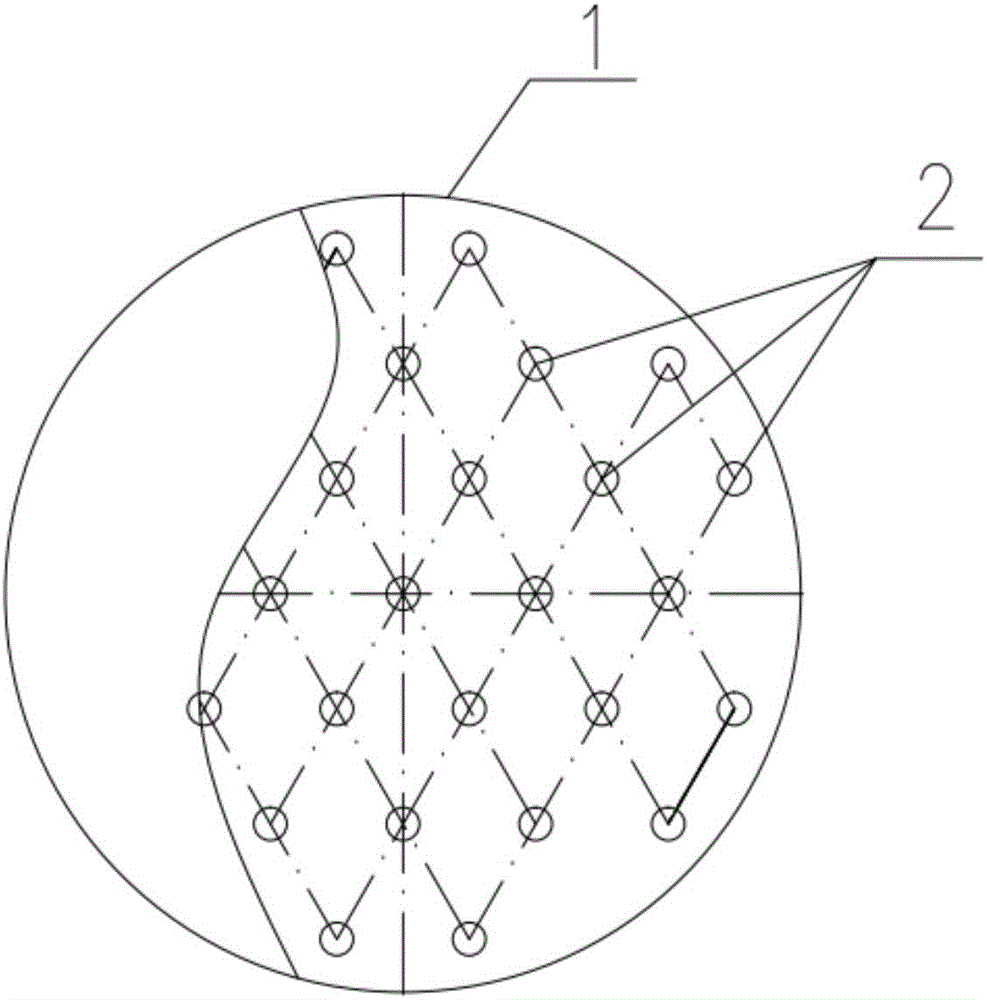

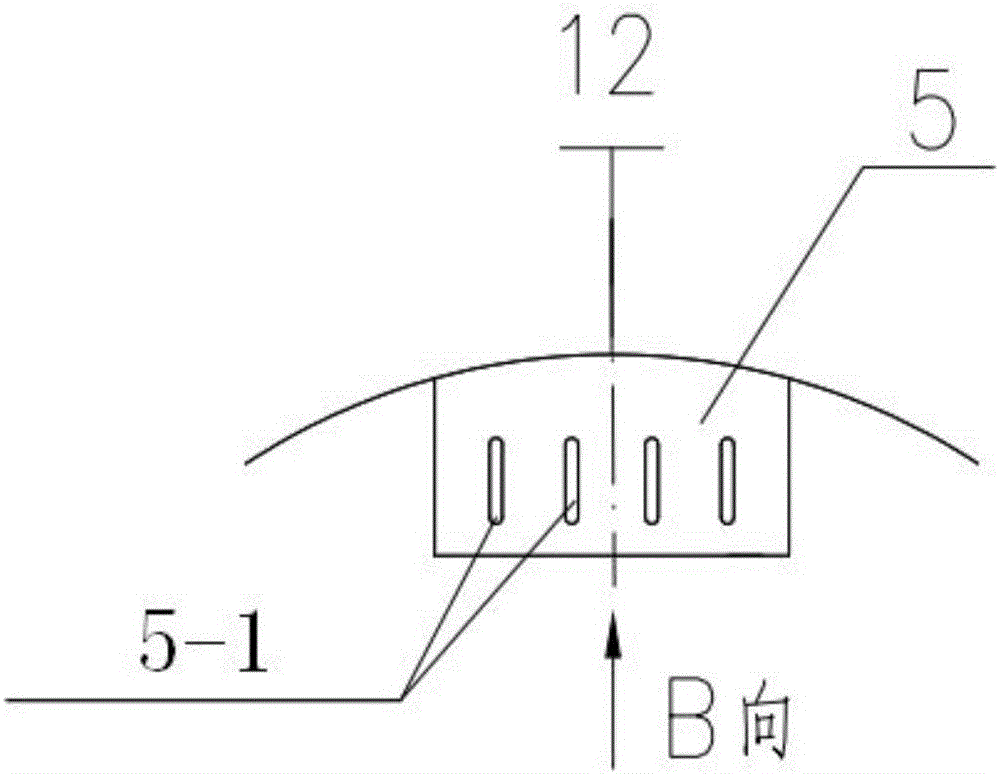

[0023] Concrete structure of the present invention sees figure 1 , 2 shown. A tubular fixed-bed reactor for mixed C4 selective co-hydrogenation of alkynes and diolefins with high concentration, the reactor is a tubular fixed-bed reactor, including shell 1, tubular 2, function The functional nozzle and internal parts; the solid co-hydrogenation catalyst used for selective co-hydrogenation of mixed carbon four is filled in the column tube 2; the functional nozzle and internal parts of the reactor include: multi-specification ceramic balls 3, Inlet distributor 4, outlet collector 5, discharge port 6, material inlet 7, circulation port 8, water inlet 9, water outlet 10, safety valve port 11, material outlet 12, exhaust port 13 and discharge port 14. It is used to support the solid co-hydrogenation catalyst in the tubes, and the multi-specification ceramic balls 3 that play a role in distribution are arranged in the lower part of the reactor in multiple layers; an inlet distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com