Forming system and method for three-dimensional layered vascular stent with bifurcated structure

A vascular stent, three-dimensional layered technology, applied in stents, instruments, prostheses, etc., can solve the problems of the three-layer structure of the difficult-to-stent blood vessel and the vascular bifurcation shape in the three-dimensional space of the difficult-to-stent, achieving a high degree of automation and a simple and reliable structure. , the effect of short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

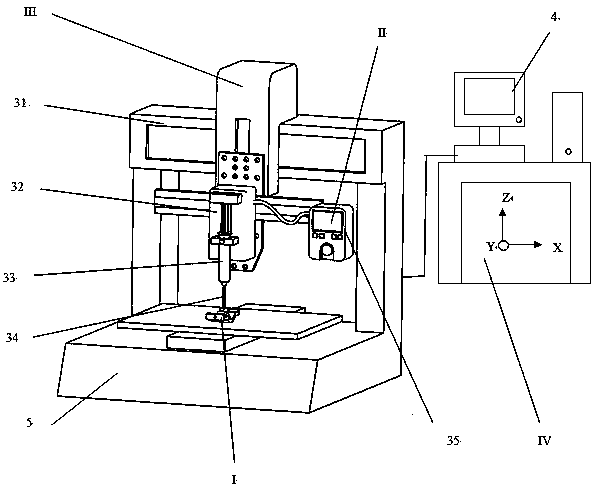

[0054] see Figure 1 ~ Figure 3 , the forming system of the bifurcated three-dimensional layered vascular stent, including the frame (5), the mold system (Ⅰ), the hydrogel perfusion system (Ⅱ), the sacrificial material printing system (Ⅲ) and the computer control system (Ⅳ) , characterized in that: the mold system (I) is placed on the base of the frame (5); the hydrogel perfusion system (II) is movably installed on the frame (5), so that one of the syringe needles ( 34) Connecting a mold inlet conduit (24) of the mold system (I); the sacrificial material printing system (III) is installed on the frame (5) and connected to drive the hydrogel perfusion system (II) to move; The computer control system (IV) is electrically connected to control the three-dimensional movement of a three-dimensional motion mechanism (31) in the sacrificial material printing system (III) and a syringe piston cylinder B (33) to extrude the sacrificial material.

Embodiment 2

[0056] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

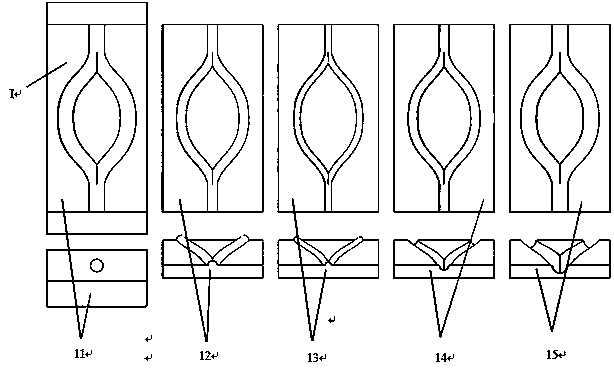

[0057] Described mold system (I) comprises mold 1 (11), mold 2 (12), mold 3 (13), mold 4 (14) and mold 5 (15); The entrance and the outlet of mold 1 (11) two ends are respectively Connected with inlet conduit (24) and outlet conduit (25); in the process of perfusion hydrogel, mold 2 (12), mold 3 (13), mold 4 (14) and mold 5 (15) convex or concave The lower path matches with the concave path of the mold 1 (11) respectively.

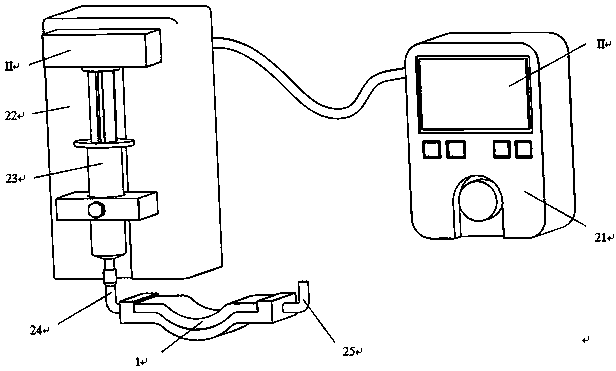

[0058] The hydrogel perfusion system (II) consists of micropump controller A (21), micropump actuator A (22), syringe piston barrel A (23), inlet conduit (24) and outlet conduit (25) Composition: Syringe piston barrel A (23) is installed on the micropump actuator A (22) and is fixed by the set bolt, and the micropump actuator A (22) is driven by the micropump controller A (21). Syringe piston cylinder body A (23) carries out the extruding of hydrogel,...

Embodiment 3

[0062] The forming method of the bifurcated three-dimensional layered vascular stent adopts the above-mentioned system for operation, and the operation steps are as follows:

[0063] 1) Forming the lower half of the outer layer of the vascular stent: combining mold 1 and mold 2 so that the axes of the respective pipes coincide. After the mold is closed, inject the hydrogel solution through the inlet conduit on one side of the mold 1 through the syringe needle until the solution flows out from the outlet conduit on the other side of the mold 1. After the hydrogel solution gels, remove the mold 2 , the lower half layer structure of the outer layer of the stent can be obtained;

[0064] 2) Forming the lower half of the inner layer of the vascular stent: combining the mold 1 and the mold 3 so that the axes of the respective pipes coincide. After closing the mold, inject the hydrogel solution through the inlet conduit on one side of the mold 1 through the syringe needle until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com