Anti-blocking pressure compensation water irrigator with uniform outlet flow and self-adjusting function

A technology of pressure compensation and outlet flow, applied in watering devices, horticulture, botanical equipment and methods, etc., can solve problems such as difficult to achieve water-saving irrigation, sacrifice the hydraulic performance of flow channels, and reduce water use efficiency, so as to alleviate agricultural problems. Shortage of water resources, improvement of comprehensive utilization rate and efficiency, and effect of increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

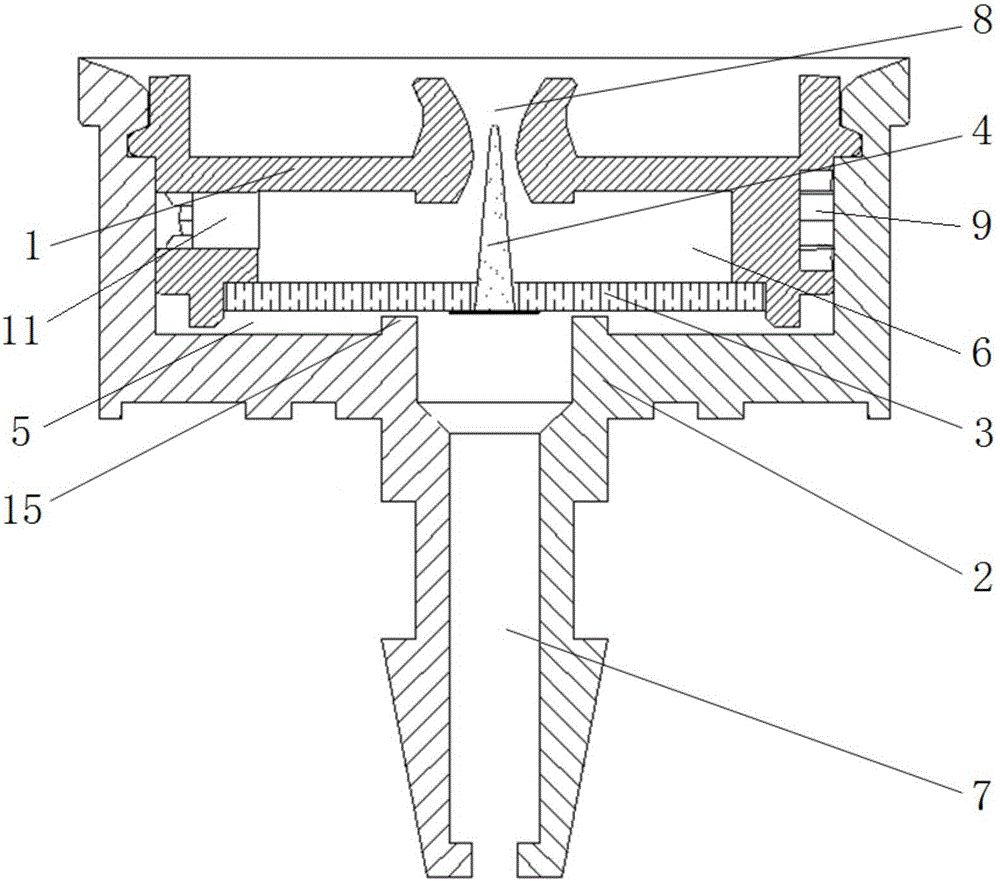

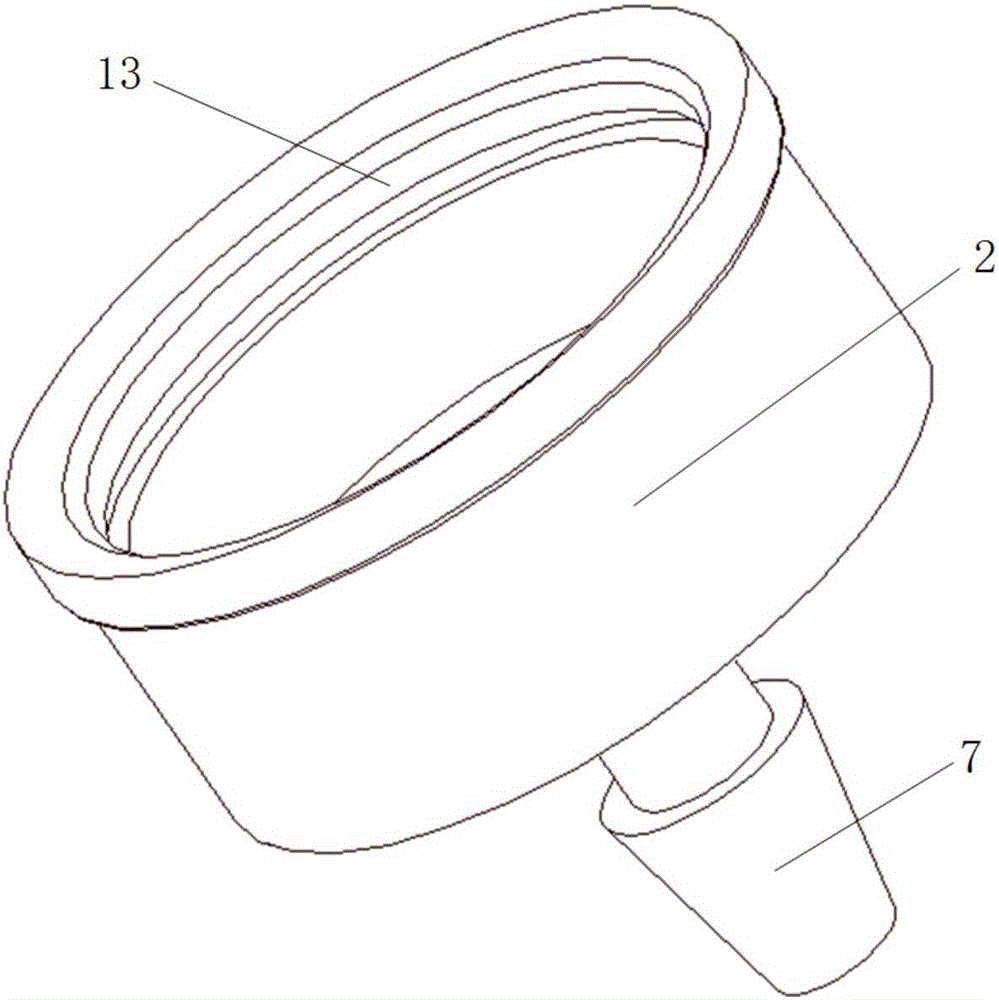

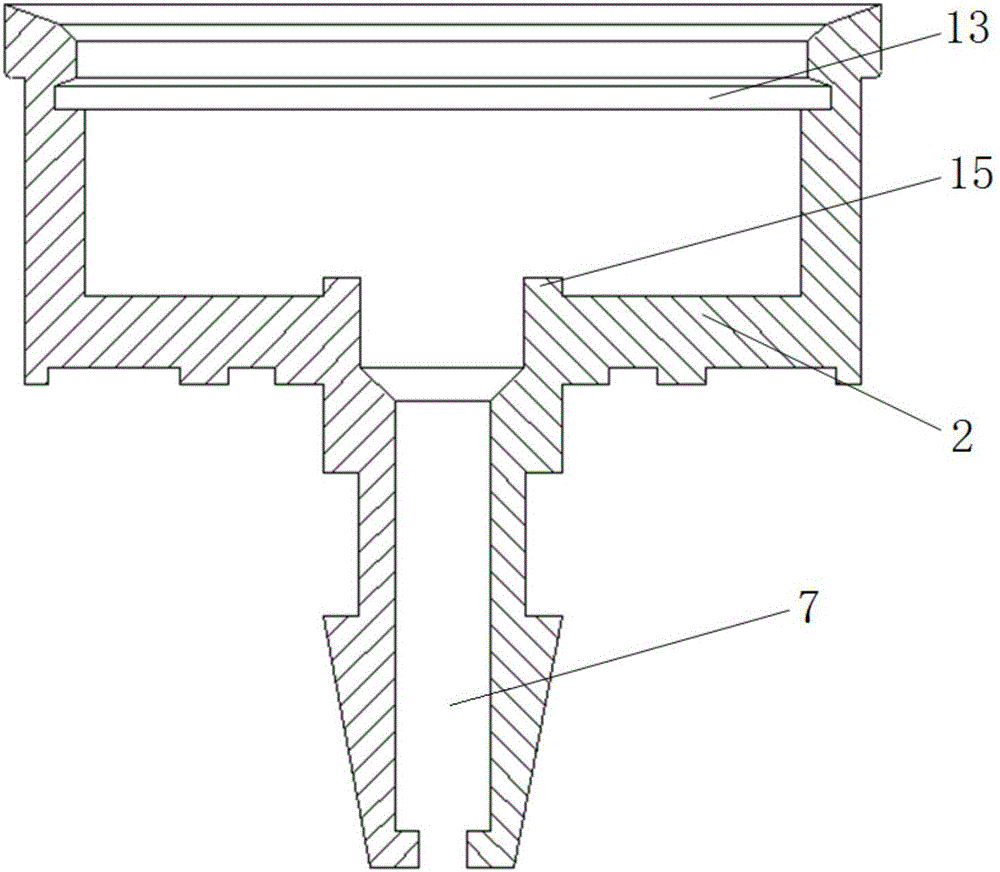

[0025] Such as Figure 1~4 As shown, the present invention includes a base 1 , a housing 2 , a pressure compensation gasket 3 and an adjustment needle 4 . Wherein, the housing 2 is buckled on the base 1 , and the inner sidewall of the housing 2 is attached to the outer sidewall of the base 1 . The pressure compensating gasket 3 is installed on the base 1, and the space enclosed by the housing 2 and the base 1 is divided into two independent cavities, wherein the cavity between the pressure compensating gasket 3 and the housing 2 The body is the first cavity 5, the cavity between the pressure compensating gasket 3 and the base 1 is the second cavity 6, and the housing 2 is provided with a water inlet 7 communicating with the first cavity 5. The base 1 is provided with a water outlet 8 communicating with the second cavity 6 . The outer wall of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com