Elevator door plate spraying automatic loading and blanking device

A door panel and elevator technology, applied in the field of elevator machinery, can solve the problems of human injury, high labor intensity, low processing efficiency, etc., and achieve the effects of reducing labor, saving labor, and avoiding injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

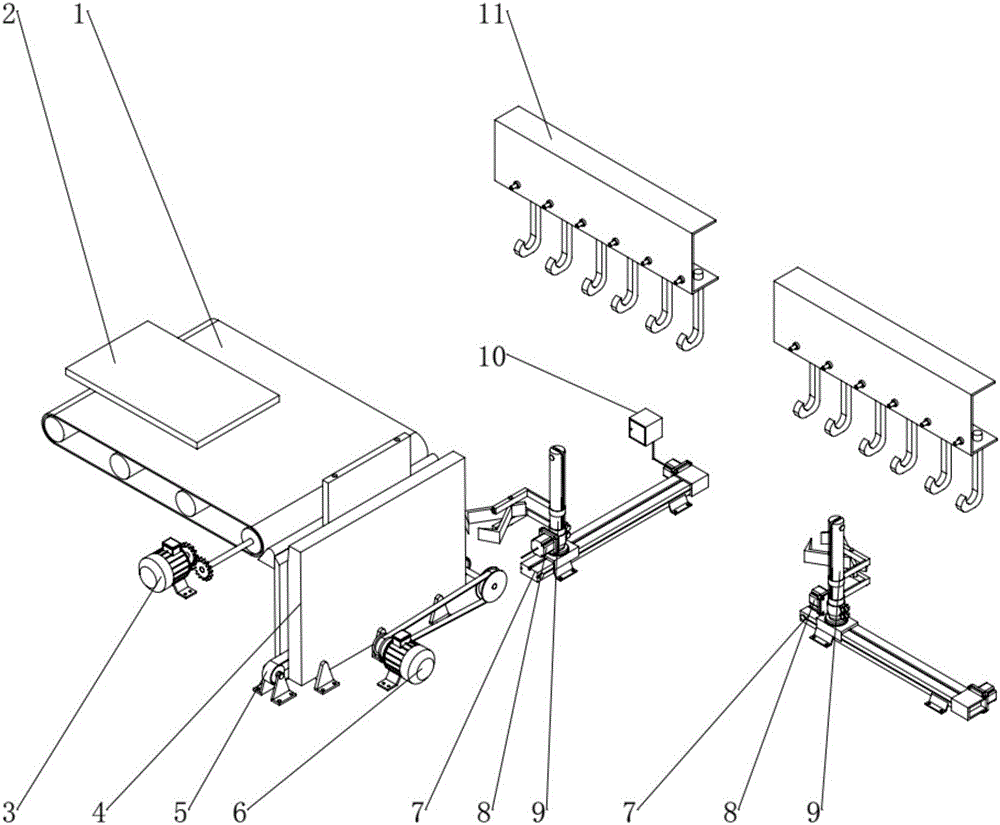

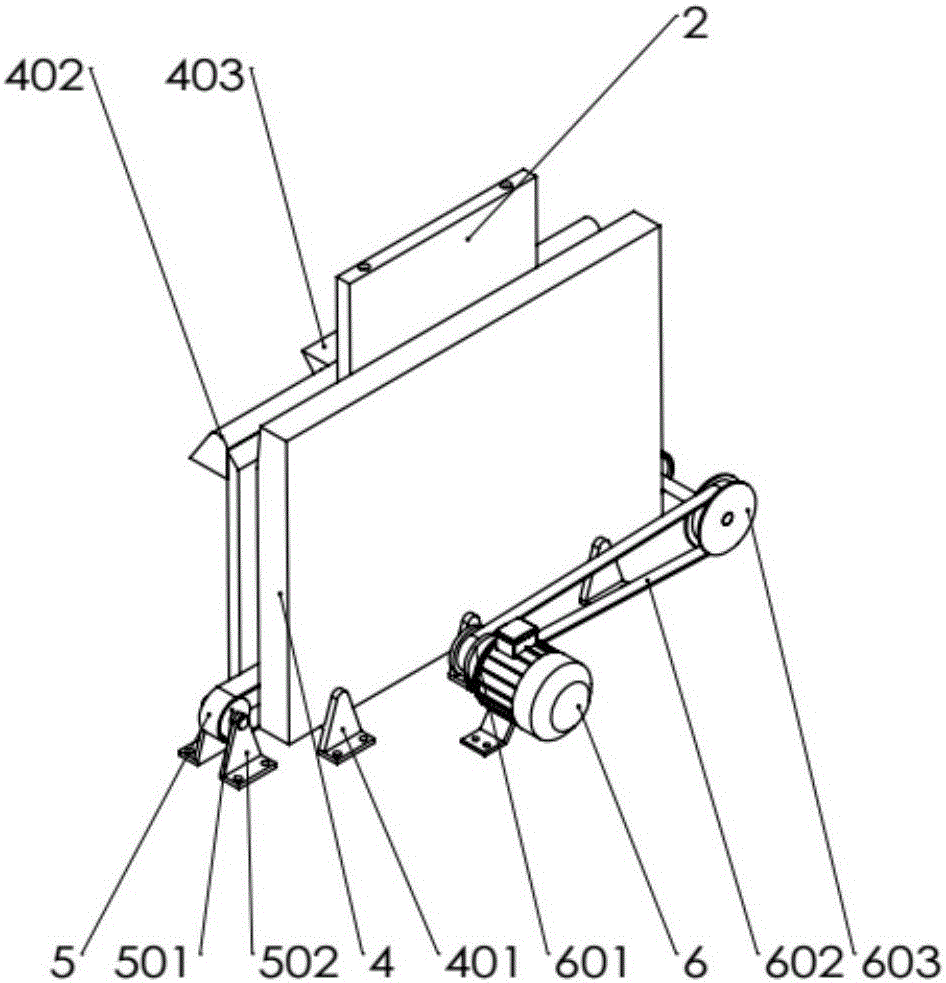

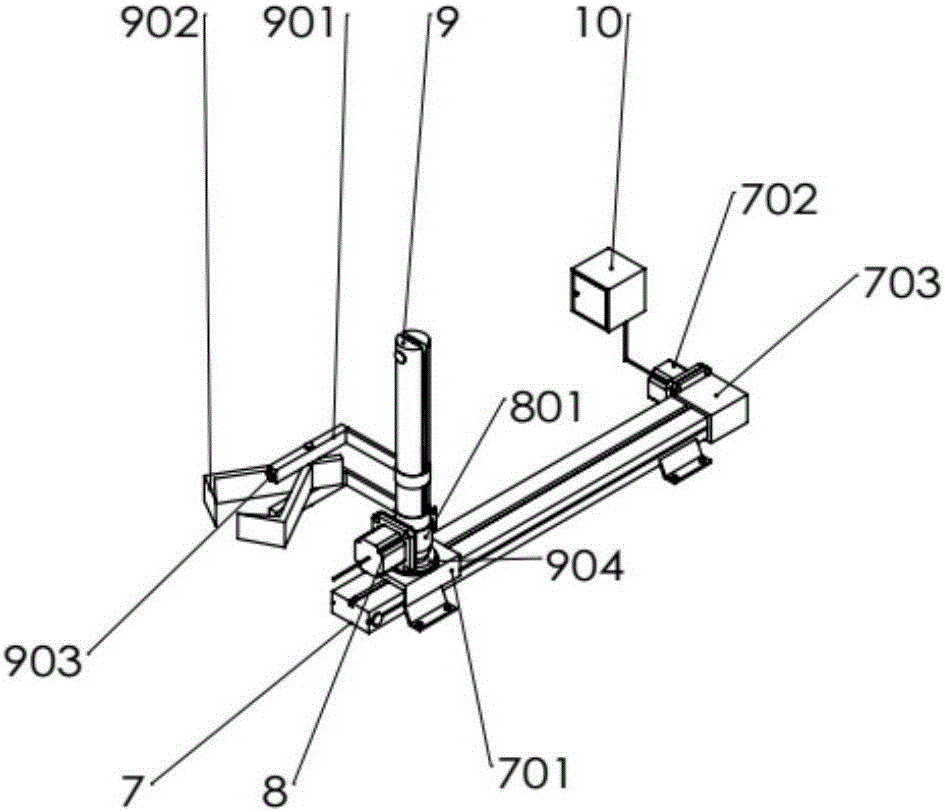

[0022] An automatic loading and unloading device for elevator door panel spraying, which is composed of a door panel conveyor belt 1, a conveyor belt roller 101, an elevator door panel 2, a conveyor belt motor 3, a conveyor belt motor gear 301, a high and low vertical baffle 4, a high and low vertical baffle bracket 401, and an arc Lower slider 402, arc lower slider bracket 403, door panel erection conveyor belt 5, door panel erection conveyor belt roller 501, door panel erection conveyor bracket 502, door panel erection conveyor belt motor 6, door panel erection transmission small pulley 601 , V-shaped belt 602, large pulley 603 for door plate erection transmission, slide track 7 for clamping device, indexable column support 701, slide track motor 702 for clamping device, slide track motor support 703, indexable timing belt Motor 8, indexable synchronous belt motor sliding bearing 801, indexable column 9, clamping device bracket 901, clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com