Battery box side wall, assembly type assembled battery box and expandable battery box set

A combined battery and assembled technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of difficult processing, unfavorable mass production, heavy box weight, etc., and achieves low processing difficulty, convenient assembly, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

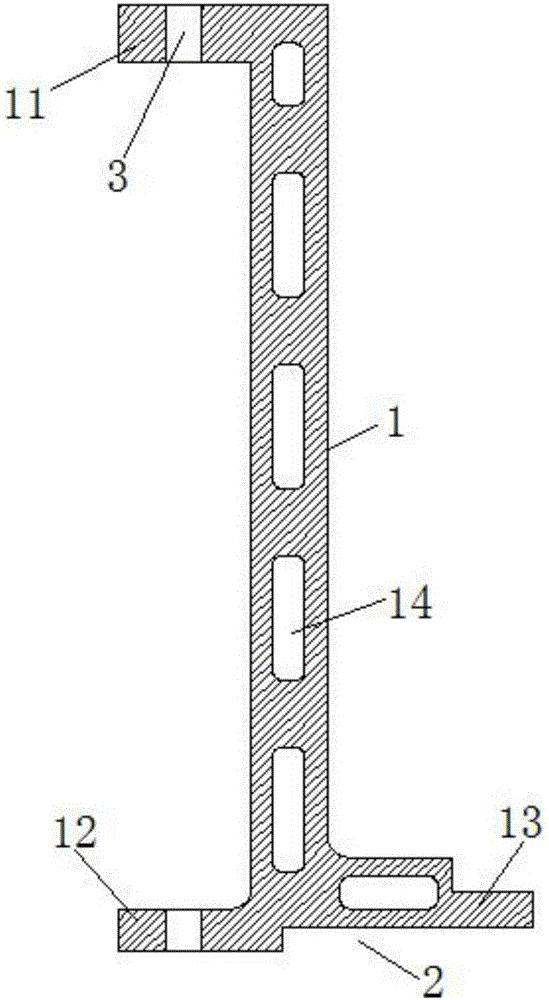

[0032] Embodiment one: if figure 1 As shown, the side wall of the battery box in this embodiment includes a side wall body 1, the top of the side wall body 1 is provided with an upper flange 11 extending horizontally to the outside, and the bottom of the side wall body 1 is provided with a lower flange extending horizontally to the outside. Flange 12, the bottom of the side wall body 1 is provided with an inner flange 13 extending horizontally inward.

[0033] During the assembly process, the upper flange 11 and the lower flange 12 are respectively connected and fixed with other parts or respectively connected with the lower flange 12 and the upper flange 11 of another side wall body 1 arranged up and down. Specifically, one side The upper flange 11 of the wall and the lower flange 12 of the other side wall are fixed by bolts, and the body 1 of the side wall abuts against each other.

[0034] Preferably, the bottom end of the lower flange 12 is lower than the bottom end of th...

Embodiment 2

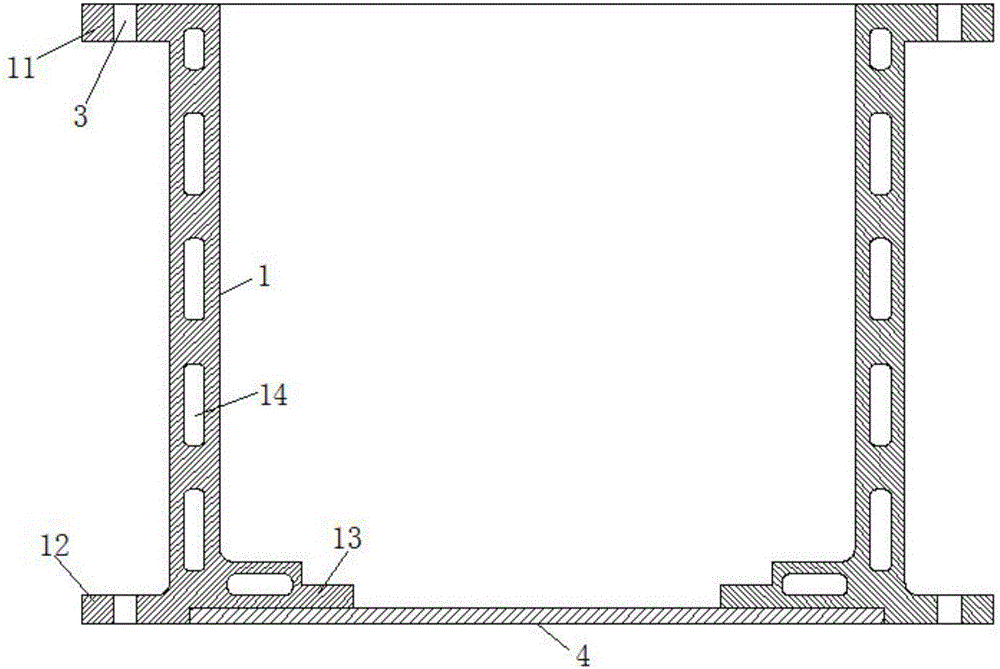

[0040] Embodiment two: if figure 2 As shown, the assembled combined battery box of this embodiment includes a bottom plate 4 and a plurality of side walls of the battery box as described in any one of claims 1 to 6, the bottom plate 4 is a polygonal structure arranged horizontally, and a plurality of the above-mentioned batteries The side walls of the box are vertically arranged and distributed at positions corresponding to each side of the bottom plate 4, and are connected end to end in turn to form a columnar frame structure, and the edges of the bottom plate 4 are respectively welded and fixed on the corresponding above-mentioned The bottom end surface of the inner flange 13 is located in the corresponding installation notch 2 , and the side end of the bottom plate 4 abuts against the side end of the lower flange 12 at the corresponding installation notch 2 .

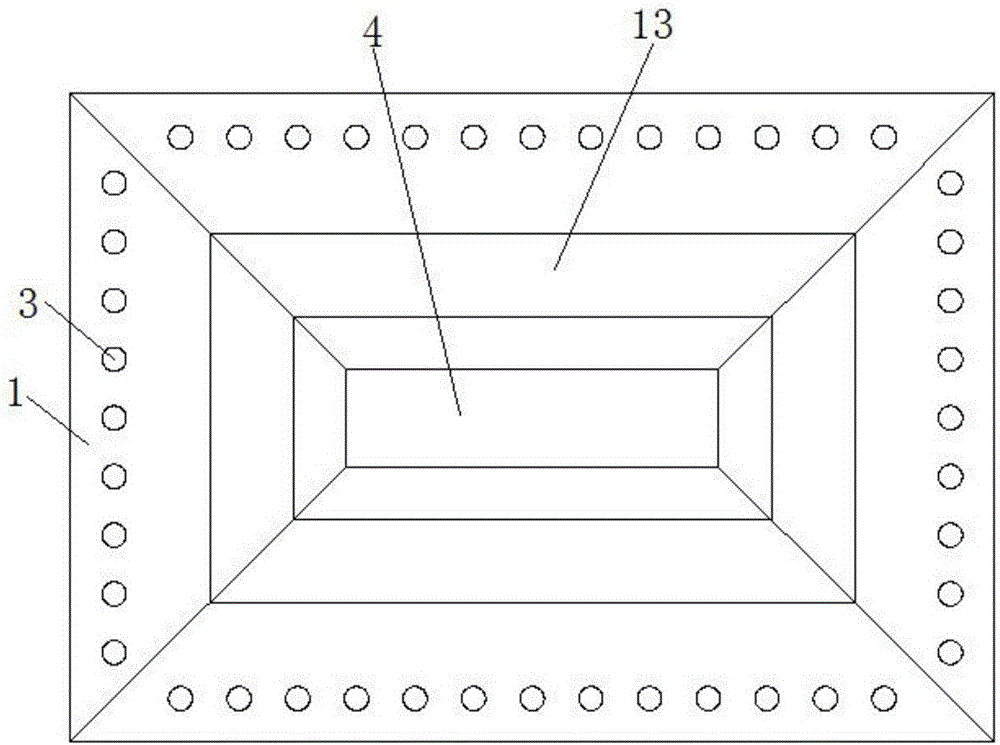

[0041] preferred, such as image 3 As shown, both sides of the side walls of the above-mentioned battery case ar...

Embodiment 3

[0043] Embodiment three: as Figure 4 As shown, an expandable battery box group includes a plurality of assembled assembled battery boxes in the second embodiment above, and a plurality of assembled assembled battery boxes are stacked sequentially from bottom to top, and two adjacent assembled assembled battery boxes The side walls correspond to each other, and the lower flange 12 at the bottom of the side wall of the assembled assembled battery box above and the upper flange 11 at the top of the side wall corresponding to the assembled assembled battery box located below are respectively fixed by bolts, The expansion and application of the battery box group is more convenient, which greatly meets the needs of users, and the expansion is more convenient.

[0044]Preferably, on the upper flange 11 and the lower flange 12 in each of the above-mentioned battery box side walls, there are correspondingly provided with several fixed reserved holes 3 passing through it, one of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com