Low-pressure large-flow water saving mechanism

A flow regulator and flow channel technology, applied in mechanical equipment, water supply devices, engine components, etc., can solve the problems of limited throttling effect and small flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

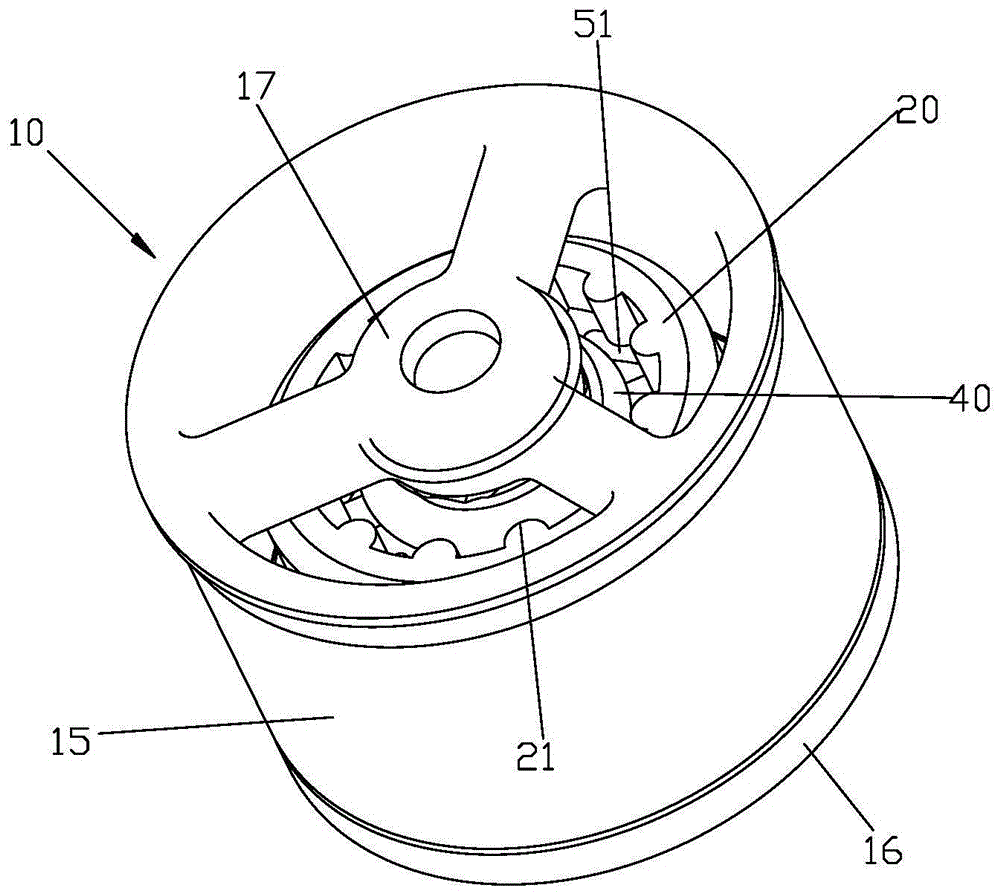

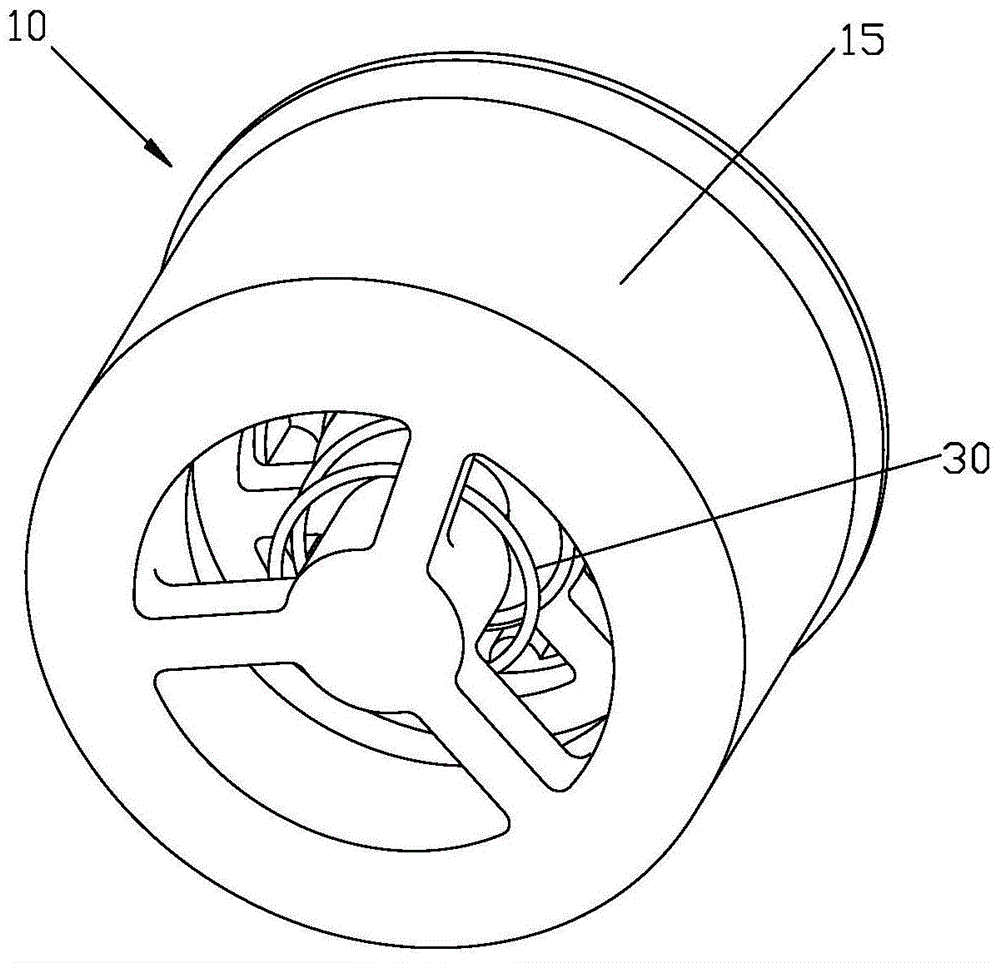

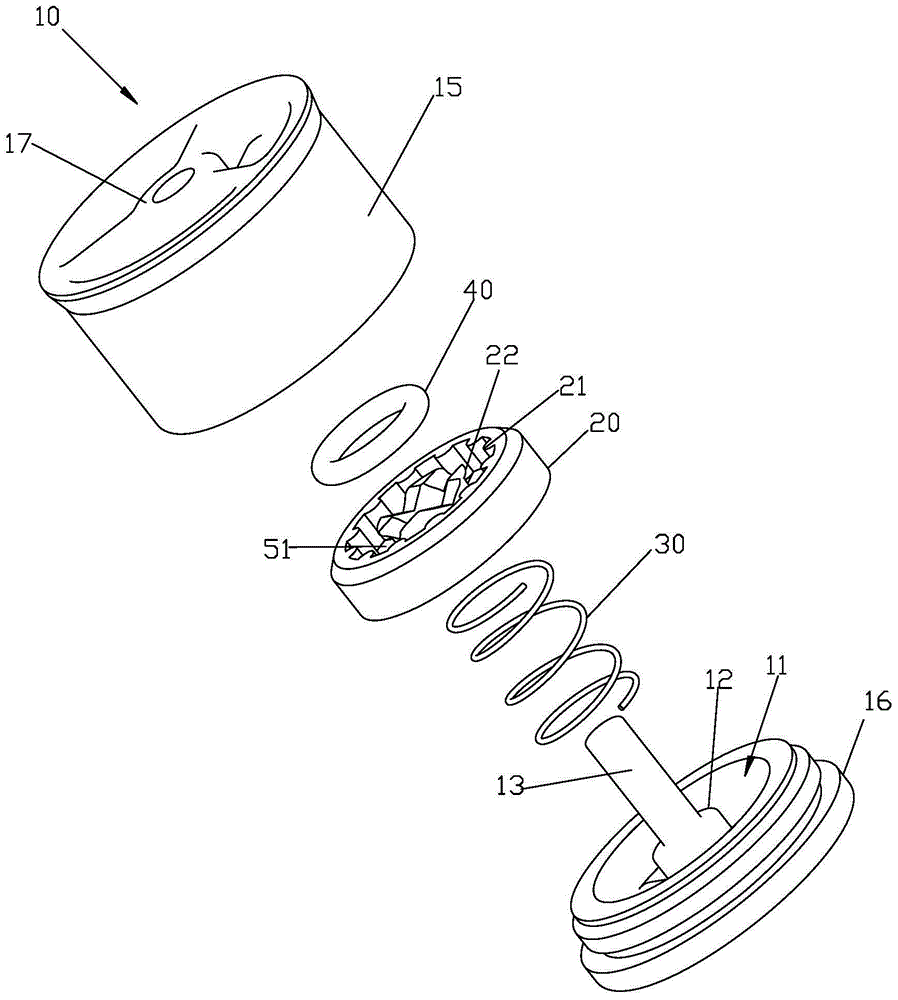

[0048] Please check Figure 1 to Figure 9 , The low-pressure and high-flow water-saving mechanism includes a solid seat 10 , a flow regulator 20 , an elastic body 30 and at least one bypass channel 52 . The flow regulator 20 has a normally open channel 51 ; the at least one bypass channel 52 is formed outside the flow regulator 20 , and the bypass channel 52 is independent from the normally open channel 51 .

[0049] The fixing seat 10 is provided with a penetrating installation space 11, and the inner wall of the installation space 11 includes a large hole wall, a small hole wall and a stepped surface connecting the large hole wall and the small hole wall. The fixed seat 10 includes a middle seat 12 located in the installation space 11, the middle seat 12 is fixed in the installation space 11 through the third spoke, and a guide column 13 is fixedly arranged on the middle seat 12.

[0050] The flow regulator 20 includes an elastically deformable throttle portion 40 .

[005...

Embodiment 2

[0059] Please check Figure 10 , it is different from Embodiment 1 in that: the diameter of the small hole wall is equal to the outer diameter of the flow regulator 20, the second position is not higher than the step surface, the top surface of the middle seat is lower than the step surface, and the flow regulator 20 is sealed and slippery. At the wall of the small hole, the bypass channel is in a closed state, and the restricting flow regulator 20 is in the second position through the top surface of the middle seat, and the restricting flow regulator 20 is in the second position.

Embodiment 3

[0061] Please check Figure 11 , it differs from Embodiment 1 in that: the fixed seat 10 is also provided with a through hole 53 that penetrates the installation space 11 inside and outside, and the inner port of the through hole 53 is located on the wall of the large hole, and the through hole also constitutes the waterway of the water saving mechanism. part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com