Damping shock absorption spring for bearing

A shock-absorbing spring and damping technology, which is applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., to achieve the effect of improving service life, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

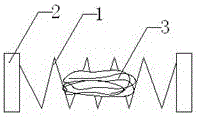

[0019] A damping and shock absorbing spring for a bearing is a compression spring and includes a spring body 1 , a shock absorbing block 2 and a metal wire 3 .

[0020] The steel wire spacing of the spring body 1 is 0.5-1.5 cm, and the spring body 1 is dip-coated with a layer of asphalt layer with a thickness of 1-3 mm, which can improve the overall damping performance of the spring.

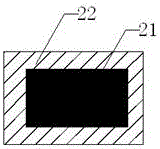

[0021] The damping block 2 is rectangular or cylindrical, and consists of an internal structure 21 and an elastic layer 22 coated on the internal structure, wherein the internal structure 21 is made of stainless steel or iron, and is connected to the two ends of the spring body 1 welding connection; the elastic layer 22 is a wear-resistant rubber layer. The overall size of the shock absorbing block 2 is larger than the width of the spring body 1 , and it is welded to both ends of the spring body 1 and closes the two ends of the spring body 1 . On the one hand, the damping block 2 plays the role...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com