Overhead building machine

A space and main technology, applied in the field of aerial building machines, can solve the problems of difficult pre-control of construction cycle, complicated and troublesome production process, and affecting the accuracy of upper-level units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0160] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

[0161] The aerial building machine provided by the present invention is suitable for high-rise and super high-rise residential buildings, and this case mainly takes the super-high-rise affordable housing with a building height of 80m to 180m and a floor height of 2.8m as the object of description, but its implementation is not based on this limit.

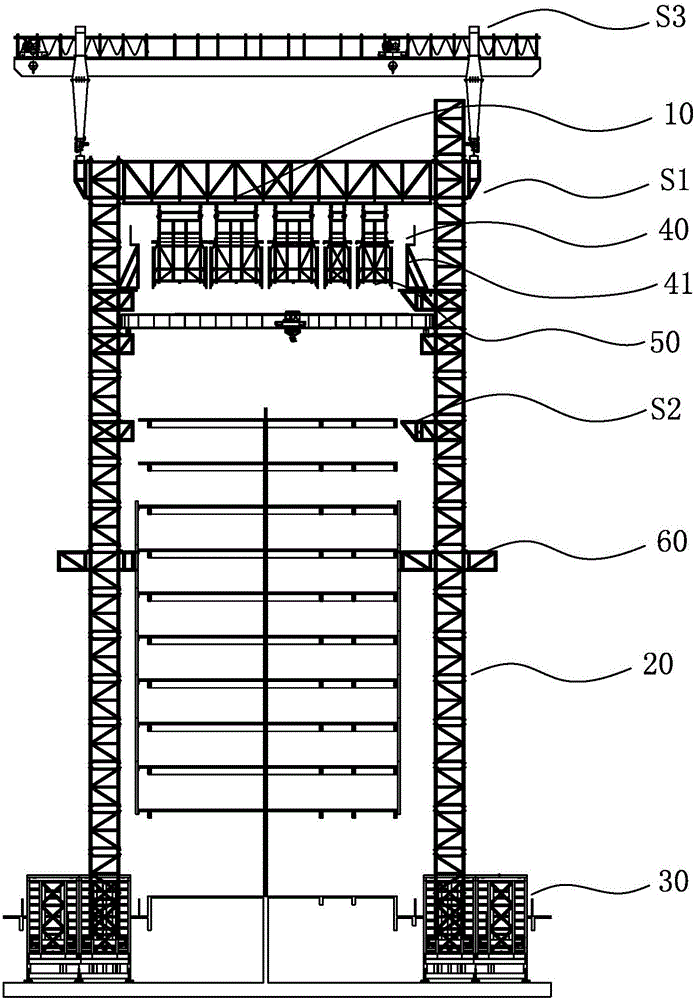

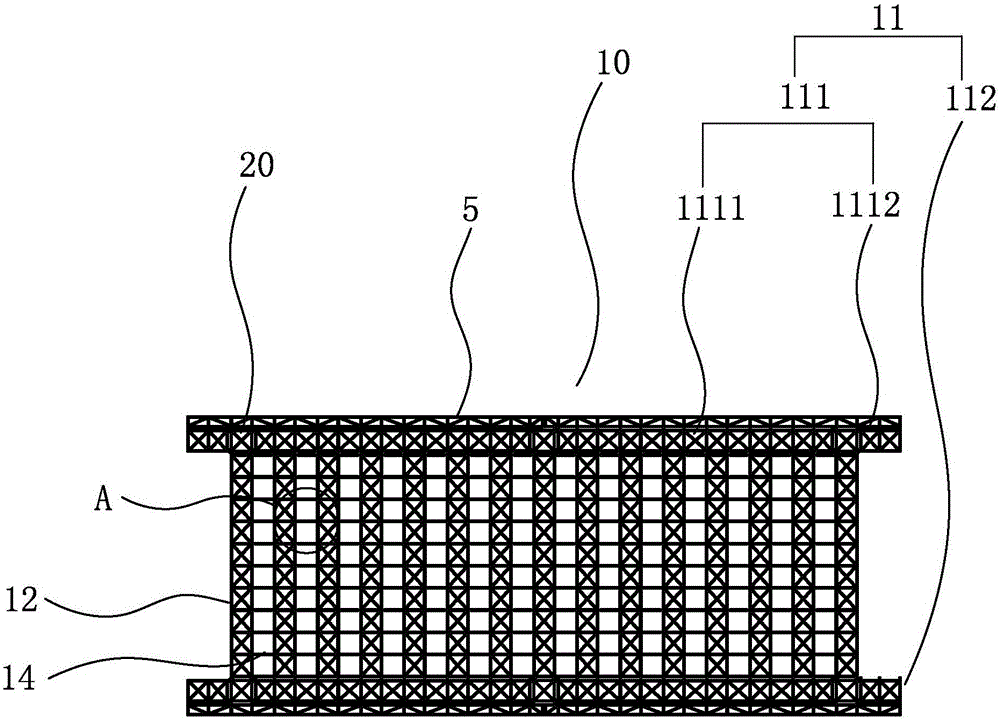

[0162] Such as figure 1 As shown, the aerial building machine includes: a main space lifting platform S1 for building residential walls, a floor construction platform S2 for pouring floor concrete, installing wall beam steel mesh and installing exterior wall insulation panels, and a gantry crane. S3, and the control system (not shown in the figure); the floor construction platform S2, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com