Method for detecting integrity of hole wall rock mass of large-diameter cast-in-place pile during pile foundation construction period of cast-in-place pile

A detection method and technology of cast-in-situ piles, which are applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve problems such as different elastic wave parameters, different elastic wave types, and different detection environments, so as to achieve small impact and reduce construction costs. Difficulty, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

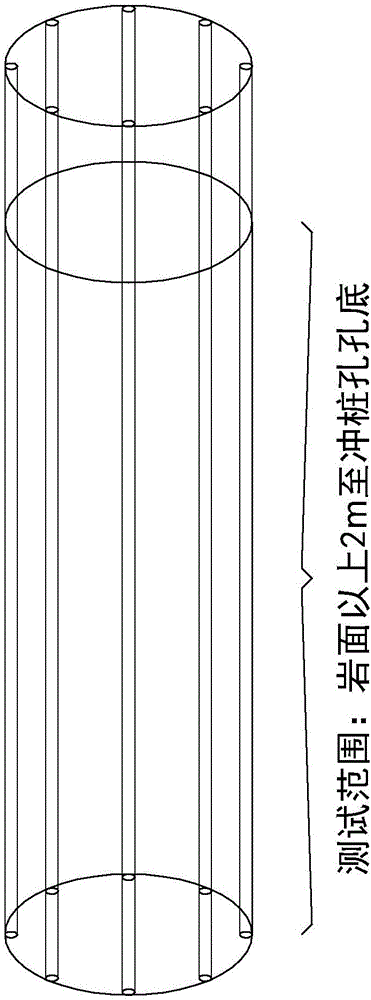

[0072] The method for detecting the integrity of the large-diameter cast-in-place pile hole wall rock mass synchronously during the construction of the cast-in-place pile foundation of the present invention was once applied to a certain project of Guangzhou Baiyun International Airport. Drilling found that the karst in this area is strongly developed.

[0073] According to the current technical specification, the depth of the final hole must be no less than 4m for the full section of the pile foundation to enter the complete rock mass. Based on this, the designer has given the estimated final hole depth for each pile position, which is generally deep. Some piles contact the bedrock from about 20m, and need to be as deep as 80m to meet the specification requirements of no less than 4m for the full section to enter the complete rock mass.

[0074] During the construction process, it was found that there were multi-layered karst caves, and although the cumulative thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com