Efficient asphalt mixing furnace

An asphalt and high-efficiency technology, applied in the field of asphalt mixing furnaces, can solve problems such as large energy loss, and achieve the effects of extending service life, reducing heat loss and reducing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

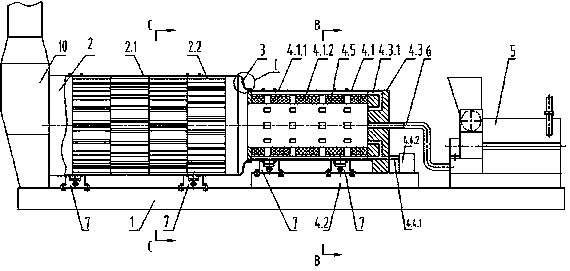

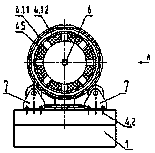

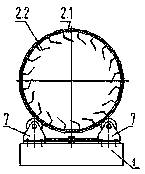

[0018] The high-efficiency asphalt mixing furnace shown in the accompanying drawings includes a barrel assembly 2, an annular baffle 3, a base 1, an igniter assembly 4, a pulverized coal grinder 5, a pulverized coal conveying pipeline 6 and four sets of roller assemblies 7 (in other embodiments , can also be more than four sets of roller assemblies 7); the barrel assembly 2 is placed flat, supported on two sets of roller assemblies 7, and the left end is connected with the exhaust emission system 10; the barrel assembly 2 includes the barrel body 2.1, the lifting plate 2.2; the inner wall of the barrel body 2.1 is provided with several lifting plates 2.2 arranged in a circumferential direction; the igniter assembly 4 includes the igniter drum 4.1, the igniter base 4.2, the ignition device 4.3, and the air supply system 4.4; the igniter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com