Novel double-mesh control device

A control device and a new type of technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of running time and insufficient flatness, and achieve high reliability, fast weaving, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

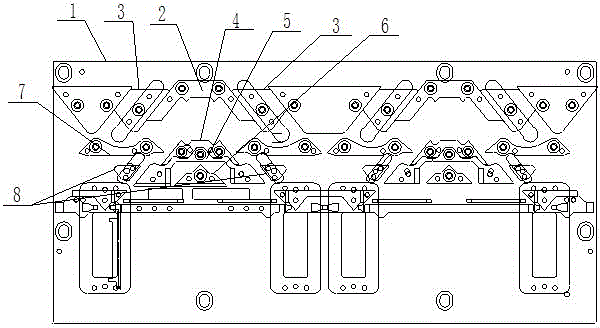

[0008] Such as figure 1 As shown, a new double-group stitch control device includes a panel body 1, a stitch triangle 1 3 and a stitch triangle 2 8 on the needle movement module. The panel body 1 is provided with a needle movement module and a needle selection module. The needle module includes: bridge cam 2, stitch cam 1 3, transfer cam 4, stitch cam 5, adjustment cam 6, guide cam 7 and stitch cam 2 8, bridge cam 2, transfer cam 4, stitch cam 5 and The guide cam 7 is arranged sequentially from top to bottom on the needle movement module, and on the same symmetrical line, there are two guide cams 7 on both sides of the transfer cam 4, and a group of stitch cams 1 and 1 are arranged on the panel body 1. A group of stitch triangle 2 8, and a group of stitch triangle 1 3 and a group of stitch triangle 2 8 are arranged symmetrically with respect to the symmetry of the bridge triangle 2, a group of stitch triangle 1 3 and a group of stitch triangle 2 8 pass through the chute slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com