Preparation method of ultra-long highly-orderly TiO2 micro/nanoscale fiber

A highly ordered, nano-scale technology, applied in fiber processing, fiber chemical characteristics, filament/wire forming, etc., can solve problems such as unseen patents and literature reports, achieve good application prospects, simple operation, and experimental reproduction good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

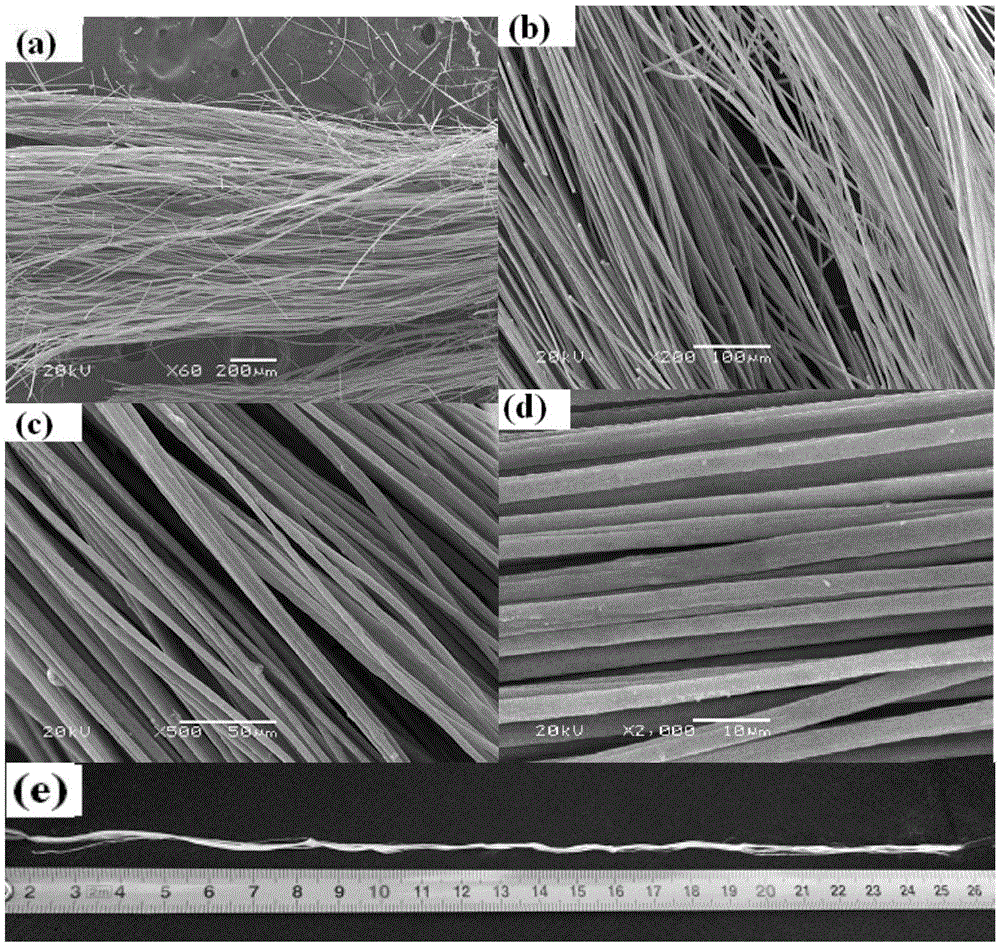

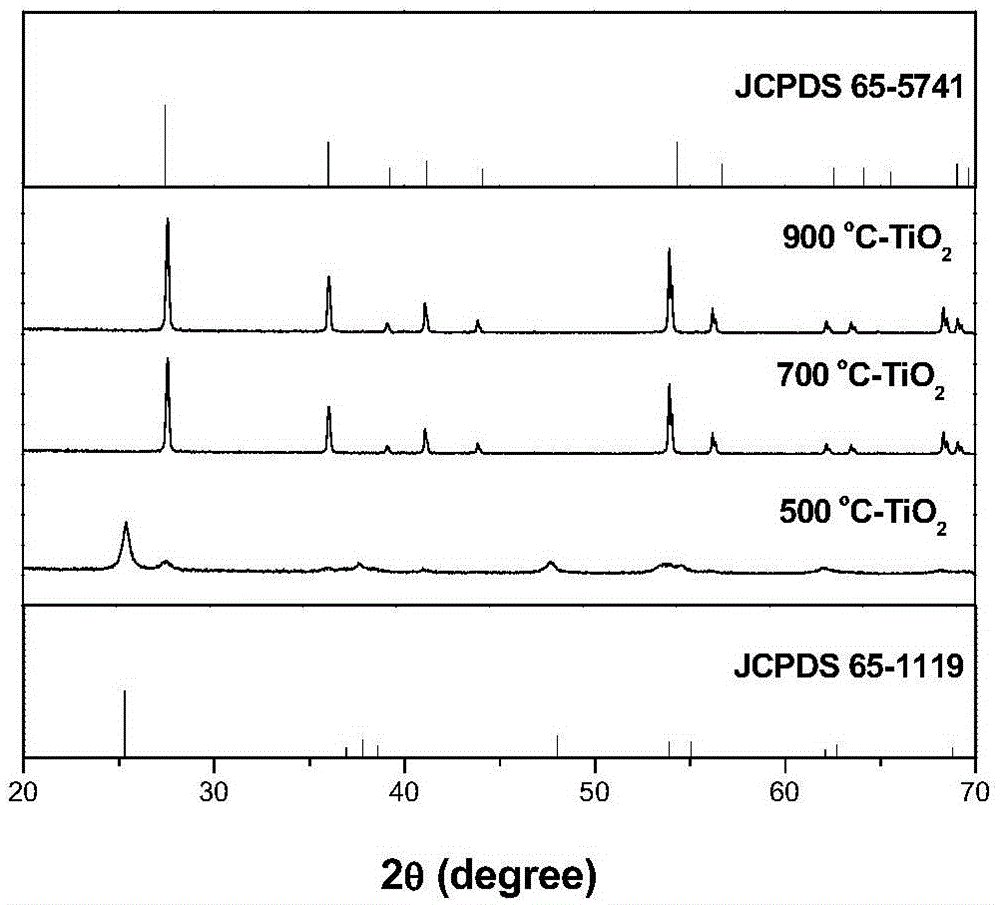

Embodiment 1

[0032] Weigh 0.8g of PEO (Mw=4000,000), dissolve it in 20ml of dichloromethane, add 2ml of tetrabutyl titanate into the above solution, stir magnetically at room temperature for 8 hours, and then let it stand for 4 hours to prepare a transparent and uniform solution. , and Ti(OC) with a certain viscosity 4 h 9 ) 4 / PEO spinning solution. The weight proportion of each component of the spinning solution is: 8% of tetrabutyl titanate, 3% of PEO, and 89% of dichloromethane. Add the prepared spinning solution into the syringe of the spinning device for electrospinning, the nozzle diameter is 2mm, the angle between the nozzle and the horizontal plane is adjusted to 30°, a DC voltage of 6kV is applied, the curing distance is 20cm, and the room temperature is 25°C. Humidity is 30%, rotating drum is used as collecting device, and rotating speed is 1100rmp (1rpm is equal to 0.0022m / s), obtains Ti(OC 4 h 9 ) 4 / PEO composite fiber. Put the prepared composite fiber into a programma...

Embodiment 2

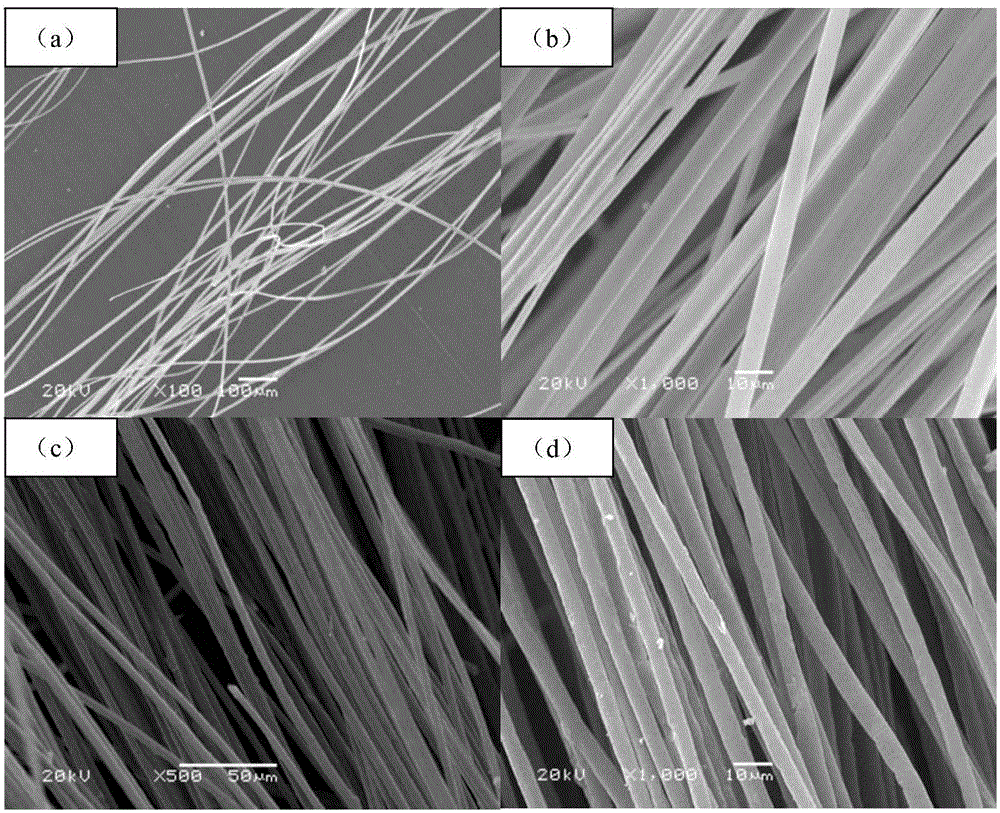

[0035] Weigh 0.8g of PEO (Mw=4000,000), dissolve it in 20ml of dichloromethane, add 2ml of tetrabutyl titanate into the above solution, stir magnetically at room temperature for 8h, and then let it stand for 4h to prepare a transparent, uniform, And Ti(OC) with a certain viscosity 4 h 9 ) 4 / PEO spinning solution. The weight proportion of each component of the spinning solution is: 8% of tetrabutyl titanate, 3% of PEO, and 89% of dichloromethane. Add the prepared spinning solution into the syringe of the spinning device for electrospinning, the nozzle diameter is 2mm, the angle between the nozzle and the horizontal plane is adjusted to 30°, a DC voltage of 6kV is applied, the curing distance is 20cm, and the room temperature is 25°C. Humidity is 30%, rotating drum is used as collecting device, and rotating speed is respectively 500,800,1100,1400rmp (1rpm is equal to 0.0022m / s), obtains four kinds of Ti(OC 4 h 9 ) 4 / PEO composite fiber. Put the composite fibers prepared...

Embodiment 3

[0038] Weigh 0.8g of PEO (Mw=4000,000), dissolve it in 20ml of dichloromethane, add 2ml of tetrabutyl titanate to the above solution, stir magnetically at room temperature for 8h, and then let it stand for 4h to make it transparent and uniform. And Ti(OC) with a certain viscosity 4 h 9 ) 4 / PEO spinning solution. The weight proportion of each component of the spinning solution is: 8% of tetrabutyl titanate, 3% of PEO, and 89% of dichloromethane. Add the prepared spinning solution into the syringe of the spinning device to carry out electrospinning. The nozzle diameter is 1mm, the angle between the nozzle and the horizontal plane is adjusted to 30°, a DC voltage of 6kV is applied, the curing distance is 20cm, and the room temperature is 25°C. Humidity is 30%, rotating drum is used as collecting device, and rotating speed is 1100rmp (1rpm is equal to 0.0022m / s), obtains Ti(OC 4 h 9 ) 4 / PEO composite fiber. The prepared composite fibers were placed in a programmable tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com