Automatic mechanical frame lifting device

An automatic lifting and mechanical technology, applied in the direction of lifting devices, etc., can solve the problems of environmental pollution around the oil, and achieve the effects of uniform force, improved stability, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

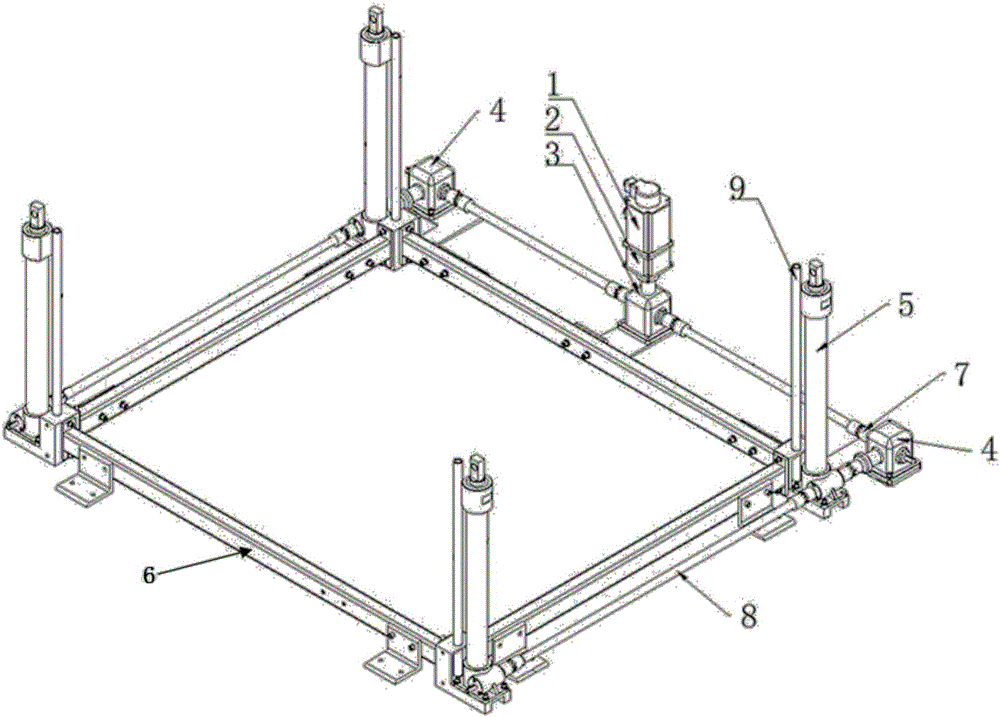

[0025] Such as figure 1 As shown, the present invention includes a support frame 6, a plurality of lifting cylinders 5 with the same height arranged on the support frame 6 and a power system. In this embodiment, two groups of lifting cylinders 5 are arranged on the support frame 6, each Each group includes two lift cylinders 5, and the support frame 6 is designed as a rectangular structure. The four lift cylinders 5 are arranged in pairs on the two parallel sides of the rectangular support frame 6, and the support frame 6 is also provided with There is a guide rod 9 parallel to the lift cylinder 5, and the top of the guide rod 9 is fixedly connected to the top of the lift cylinder 5, which can effectively stabilize the lifting direction of the lift cylinder 5;

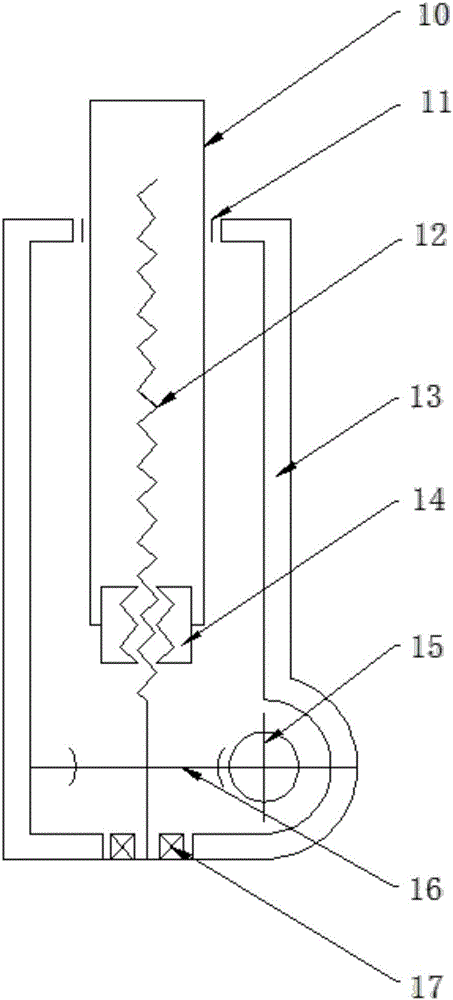

[0026] Such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com