A conveyor with a telescopic arm

A technology of conveying arms and conveyors, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high manufacturing and use costs, large space occupation, and complex recycling operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

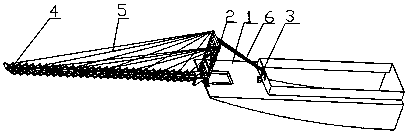

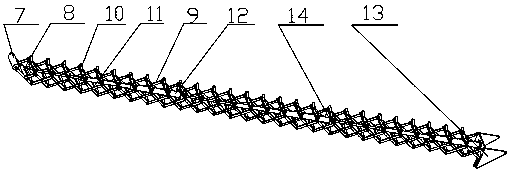

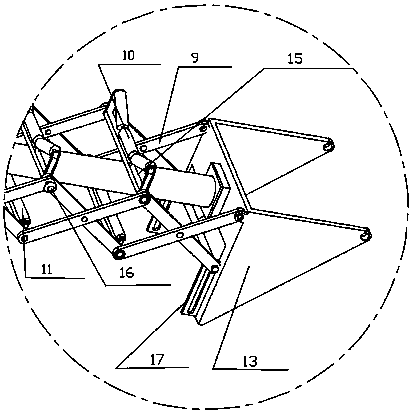

[0019] exist figure 1 Among them, a conveyor with a telescopic conveying arm, comprising a hull base 1, a gantry 2, a winch 3 and a telescopic conveying arm 4, characterized in that: the gantry 2 and the telescopic conveying arm 4 are respectively hinged to the hull base 1. On different supports, there is a pulley set in the middle of the top of the gantry 2, which is connected to the winch 3 through a wire rope. There are wire rope loops on both sides of the top of the gantry 2, and each loop is separately fixed by the wire rope and the telescopic conveyor arm 4. The wire rope suspension points 16 on both sides are connected to form a stable overall triangular structure with the gantry 2 and the jib, and can rotate together around the fixed hinge support.

[0020] In a specific embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com