Full-automatic block-shaped product continuous packing equipment

A packaging equipment, fully automatic technology, applied in the field of packaging, can solve the problems of inability to carry out continuous production, large floor space, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

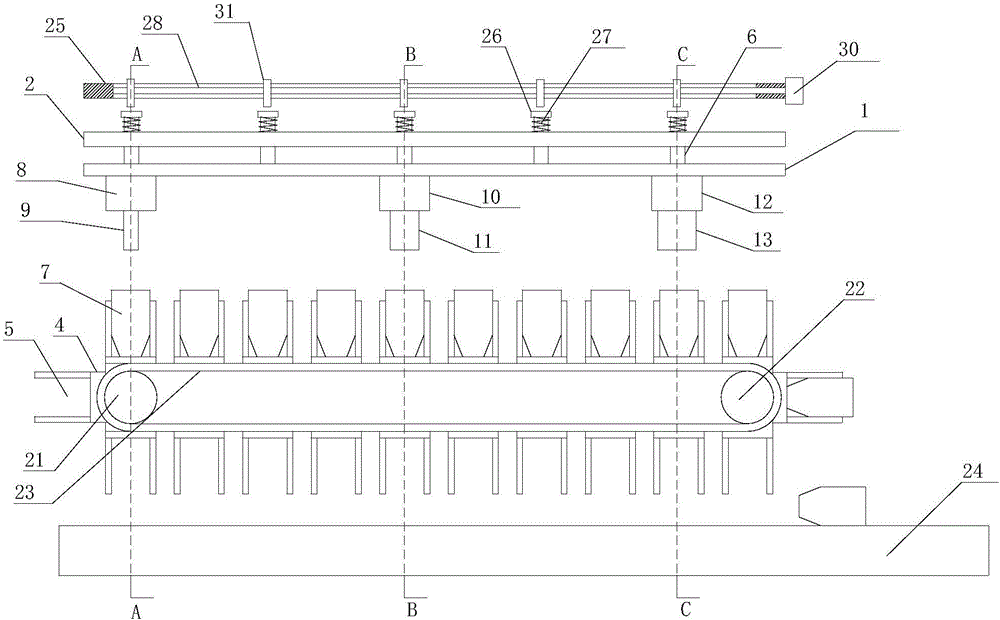

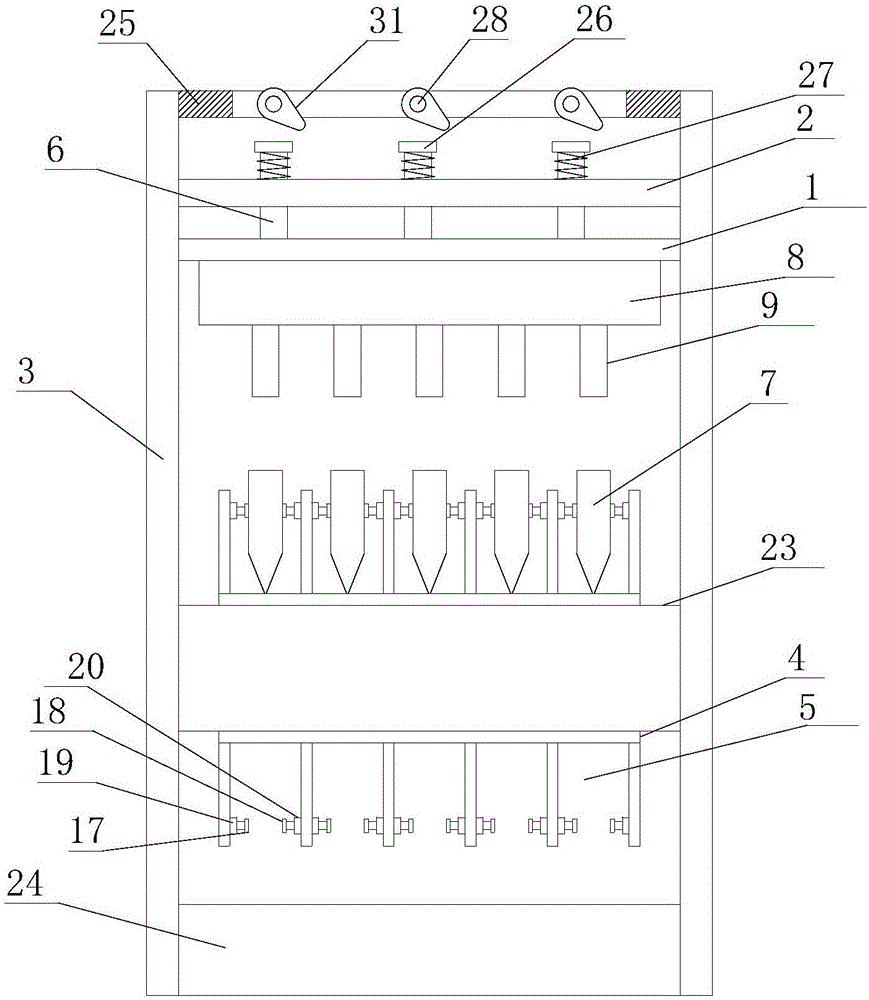

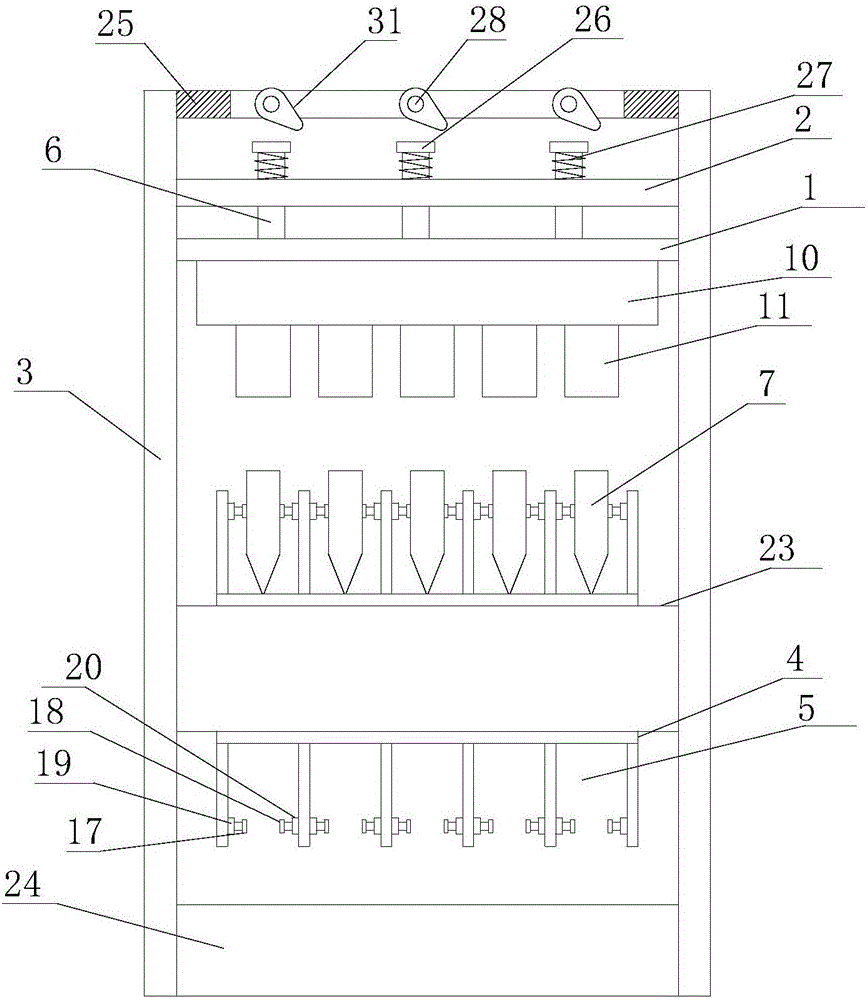

[0023] refer to figure 1 , figure 2 , image 3 , Figure 4 , the present invention proposes a fully automatic continuous packaging equipment for block products, including a first transmission mechanism, a first working frame 1, a second working frame 2, a third working frame 25, a frame 3, a power mechanism, a bag feeding mechanism, Filling mechanism, heat sealing mechanism, second transmission mechanism 24, control mechanism, wherein:

[0024] The first transmission mechanism comprises a first roller 21, a second roller 22, a transmission belt 23, the first roller 21, the second roller 22 are equal in diameter and arranged in parallel, and the transmission belt 23 is arranged on the first roller 21, the second roller 22 periphery, On the conveying surface of the conveying belt 23, a plurality of supporting platforms 4 are arranged at intervals along its conveying direction, and the extending direction of the supporting platforms 4 is perpendicular to the conveying directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com