A fully automatic multifunctional bulk product packaging equipment

A product packaging, multi-functional technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems that affect the large-scale production needs of enterprises, cannot carry out continuous production, and occupy a large area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

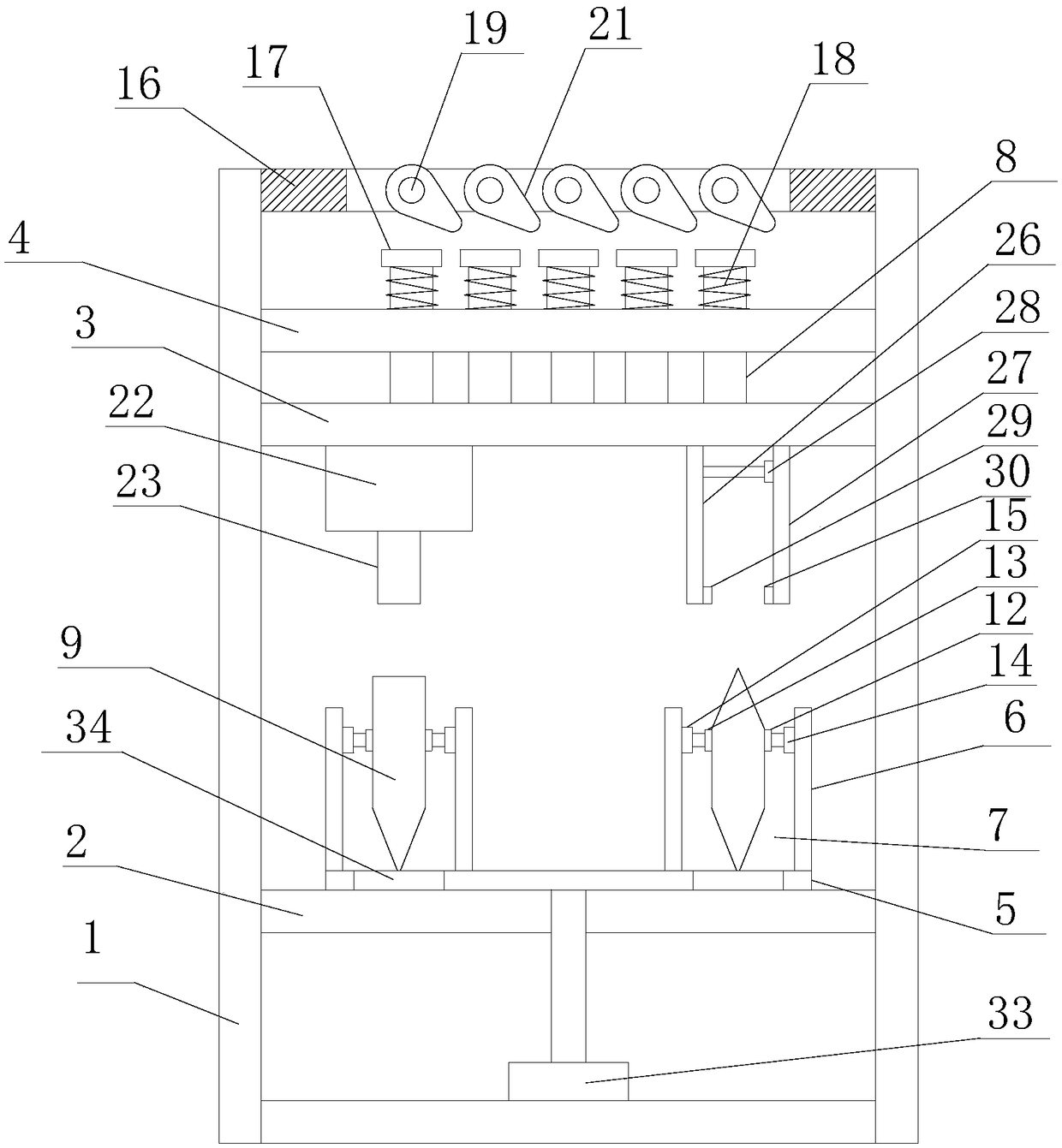

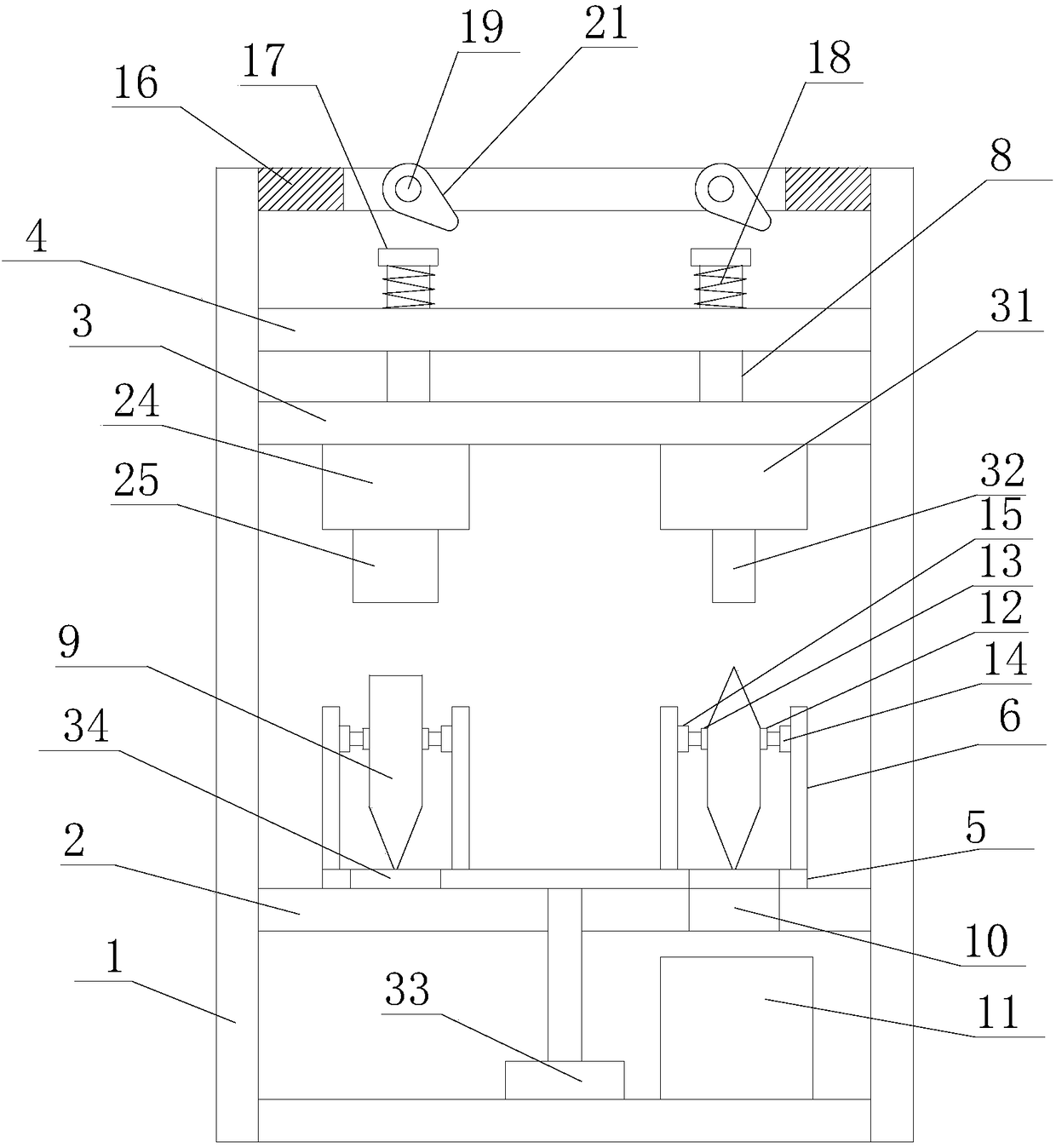

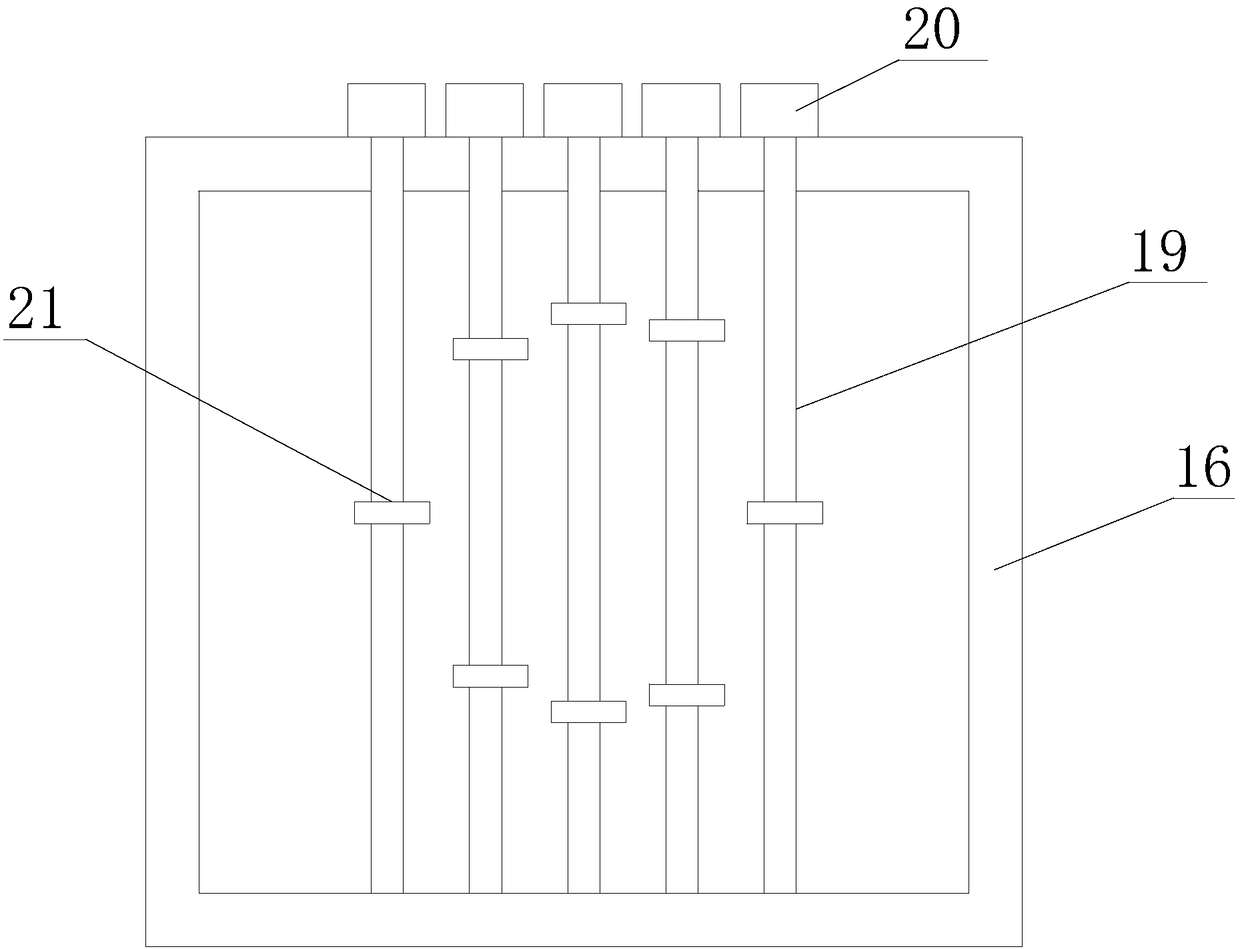

[0021] refer to figure 1 , figure 2 , image 3 , the present invention proposes a fully automatic multifunctional bulk product packaging equipment, including a frame 1, a first working frame 2, a second working frame 3, a third working frame 4, a power mechanism, a bag feeding mechanism, a filling mechanism, a heating Sealing mechanism, cooling mechanism, of which:

[0022] The first work frame 2 is arranged horizontally and the first work frame 2 is installed on the frame 1. The first work frame 2 is rotatably equipped with a turntable 5 and the turntable is driven by the first drive mechanism 33 to rotate. The turntable 5 is provided with multiple A supporting platform 6, a plurality of supporting platforms 6 are distributed in a circle around the center of the rotating disk 5, each supporting platform 6 is provided with a filling groove 7, and the filling groove 7 is provided with a bag opening assembly, and each filling groove 7 groove bottom Dodge door 34 is all provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com