L-shaped plate vibration extrusion production line

A production line and driving device technology, applied in the field of L-shaped plate vibration extrusion production line, can solve the problems of difficult unification of quality standards and low production efficiency, and achieve the effect of saving labor and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

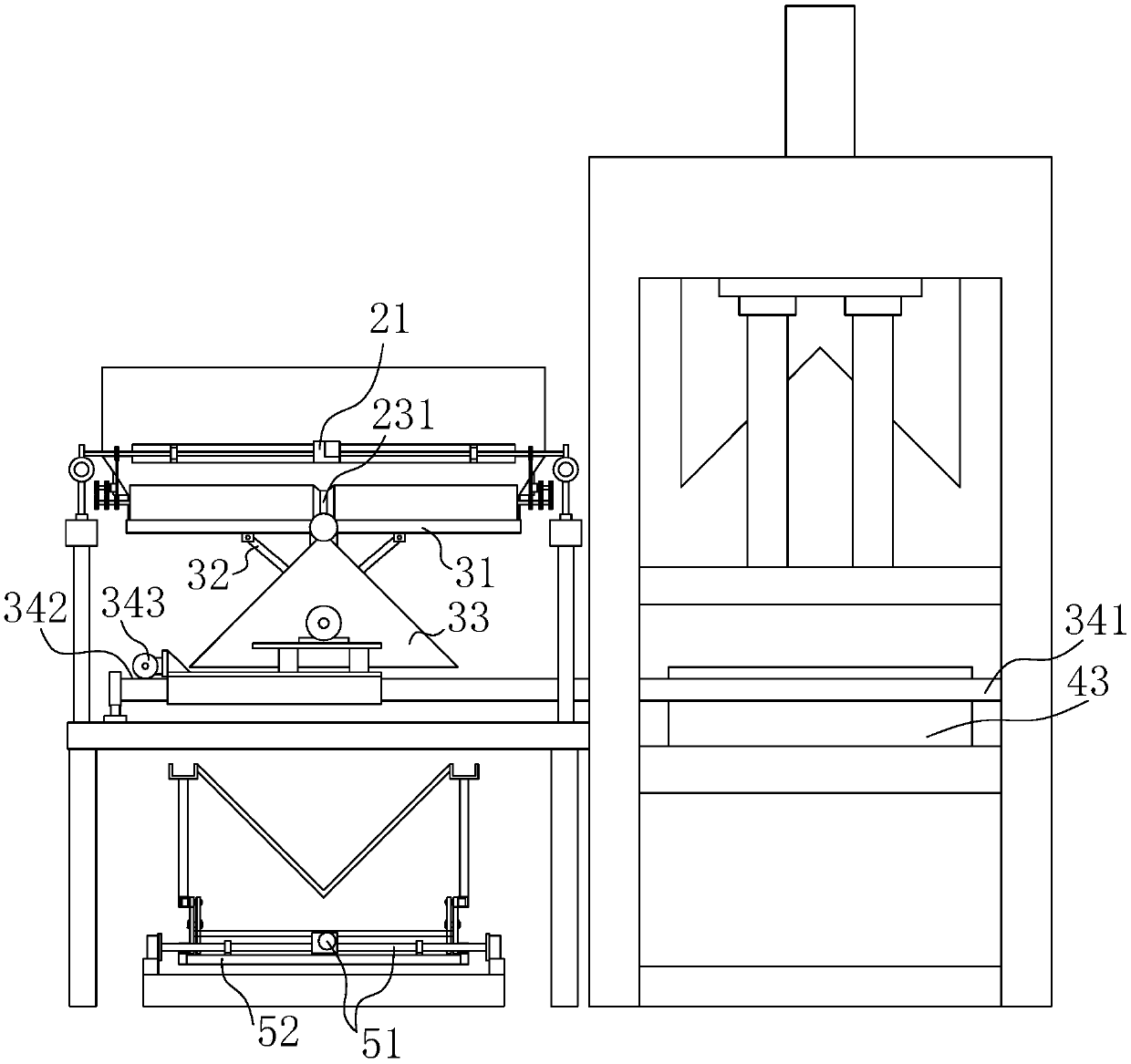

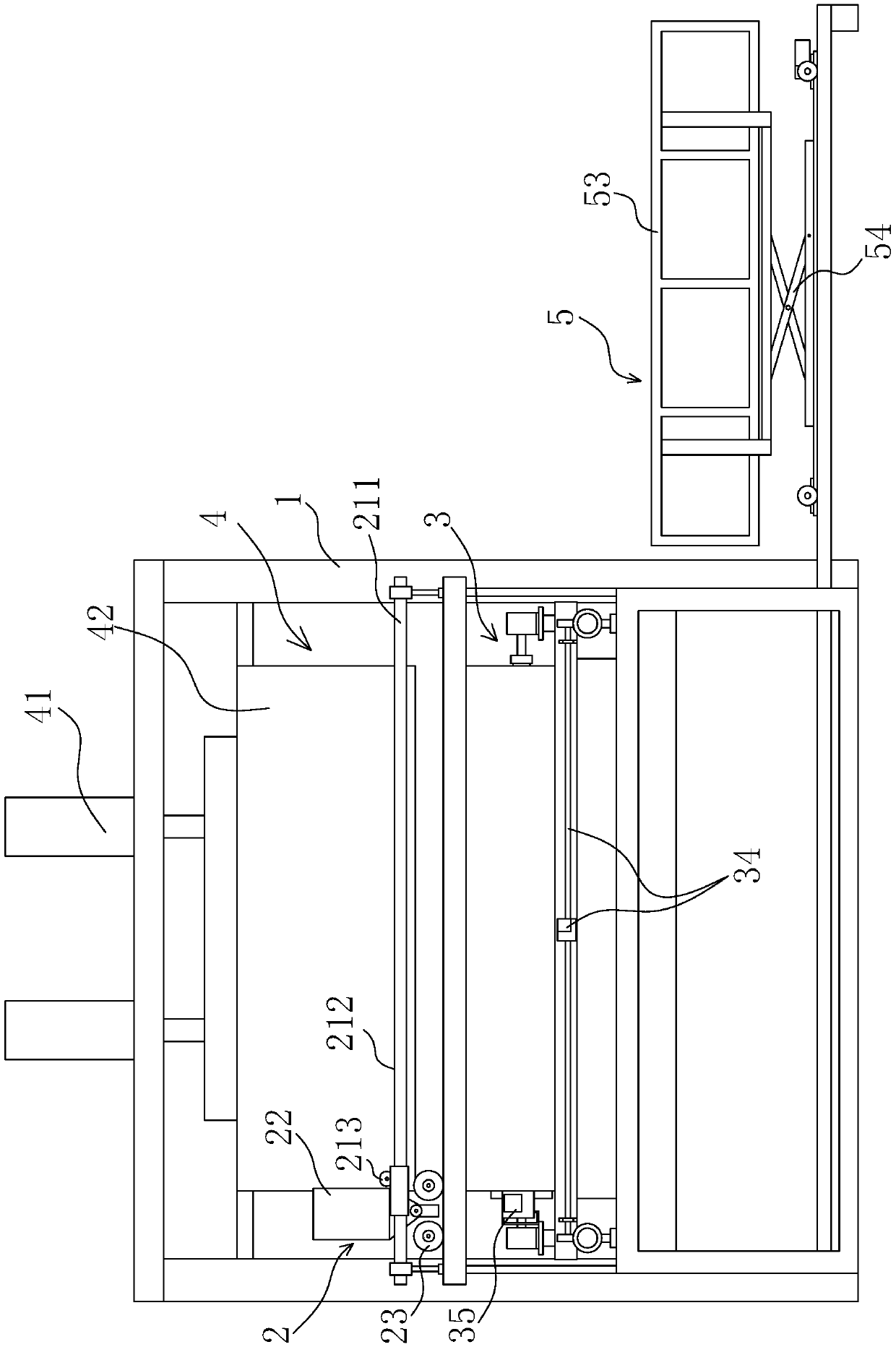

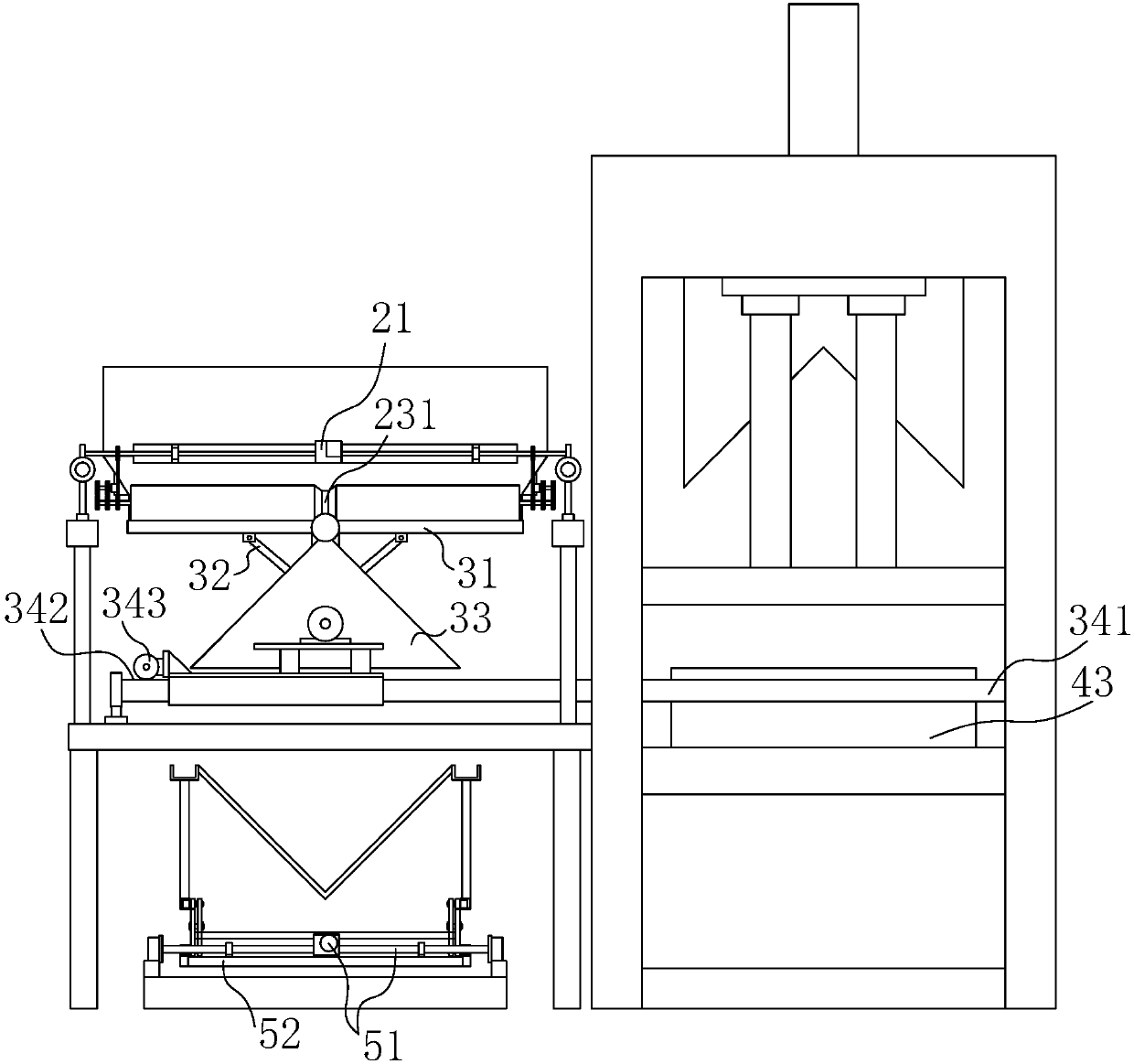

[0015] Such as figure 1 and figure 2 Shown is a schematic diagram of an embodiment of an L-shaped plate vibration extrusion production line provided by the present invention.

[0016] An L-shaped plate vibration extrusion production line, which includes a frame 1, a packing assembly 2 arranged on the frame 1, an L-shaped plate forming assembly 3 located below the packing assembly 2, and an L-shaped plate forming assembly 3 The vibrating extrusion assembly 4 on the side and the transfer assembly 5 located below the L-shaped plate forming assembly 3 .

[0017] The packing assembly 2 includes a blanking trough 22 driven by a blanking drive device 21 to move in the front and rear direction, a pair of pressing rollers 23 arranged on the front and rear sides of the blanking trough 22; groove 231 .

[0018] The blanking...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap