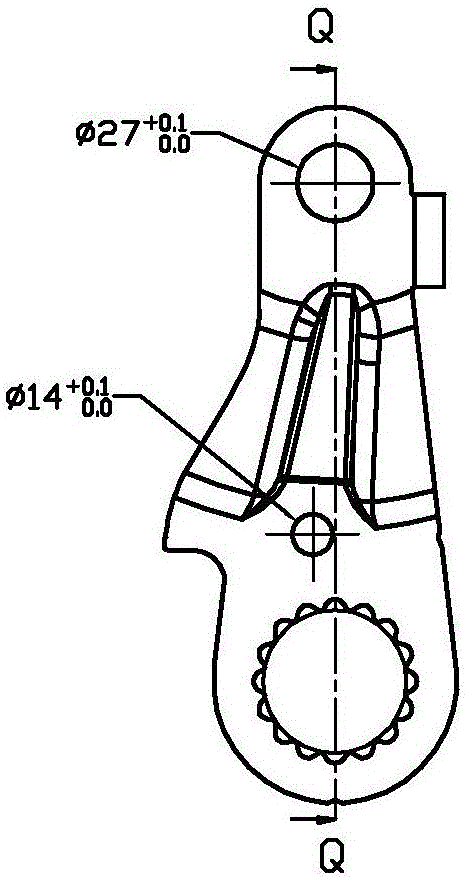

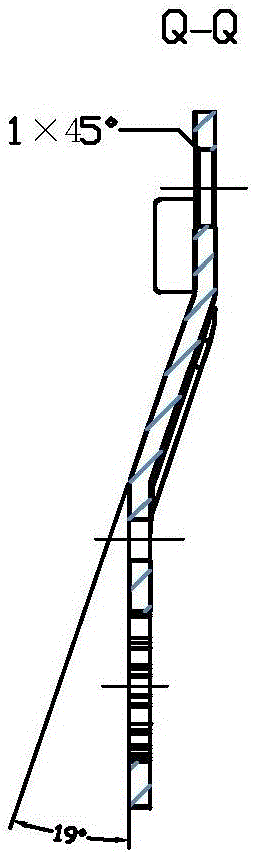

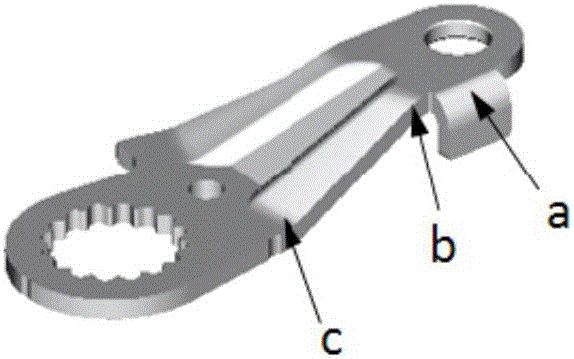

Precision progressive die for condenser support

A precision-grade, condenser technology, applied in the direction of feeding devices, forming tools, positioning devices, etc., can solve the problems of shape and size errors of unfolded materials, unguaranteed parts quality, unstable bending and springback, etc., and meet the requirements of high-quality production, Reasonable layout design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: A precision progressive die for a condenser bracket, including an upper die assembly, a lower die assembly, a discharge plate, a backing plate of the discharge plate, and a misfeed detection device,

[0032] The discharge plate 5 and the discharge plate backing plate 4 are provided with through holes that can pass through the convex or concave die on the upper mold assembly at corresponding positions. The discharge plate 5 is connected to the discharge plate backing plate 4, The material plate backing plate is installed on the upper mold assembly through the discharge spring 20 and the fixed-distance discharge stud 19,

[0033] The upper mold assembly includes an upper mold base 1, an upper backing plate 2 mounted on the upper mold base, and a convex mold fixing plate 3 connected to the upper backing plate, and the upper mold assemblies are arranged in order along the feeding direction There are 1 punching tooth-shaped hole bottom hole punch 6, 2 punching positive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com