Method for regeneration, absorption and removal of NO, alkyl nitrite, CO and N2O in tail gas from oxalate synthesis process adopting CO carbonyl coupling

A technology of alkyl nitrite and process tail gas, which is applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as polluting the environment, catalyst deactivation, and unsatisfactory effects, and achieve good social benefits and prevent pollution Atmospheric, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

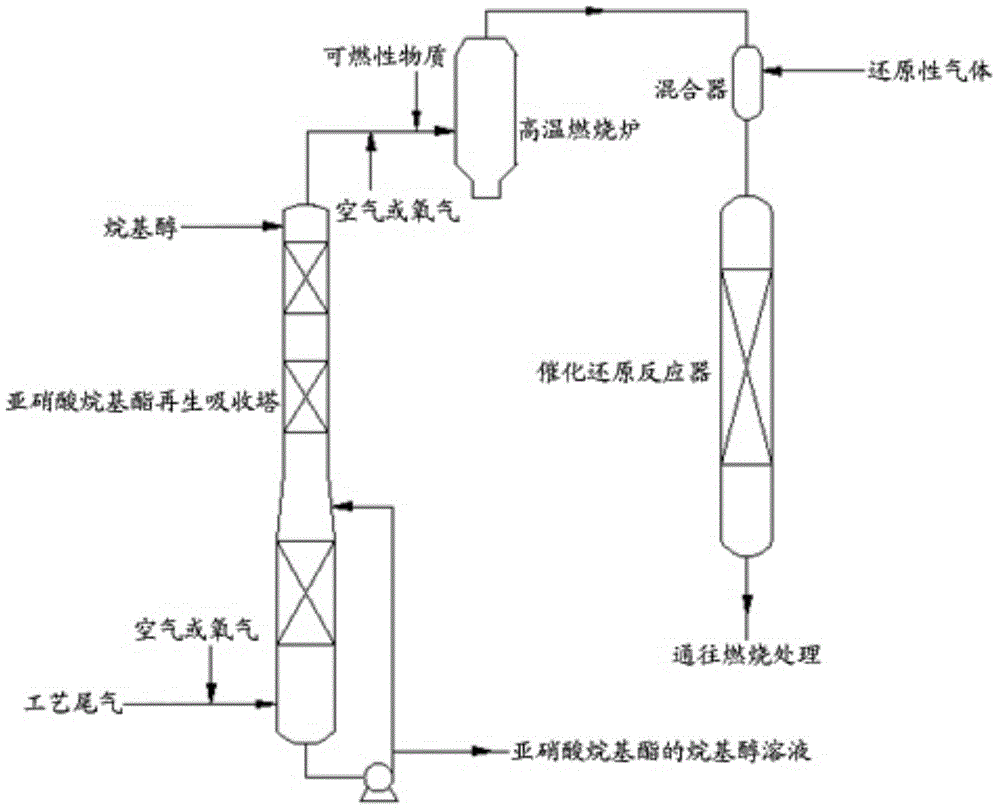

Method used

Image

Examples

Embodiment 1

[0064] according to figure 1 , will be 1378m 3 / h contains NO 3.5% by volume, CH 3 ONO 10.0vol%, CO 13.0vol%, N 2 O 0.8% by volume and balance N 2 CO carbonyl coupling synthesis of oxalate process tail gas with 512m 3 / h air is sent from the bottom of the tower into the packed tower as the regeneration absorption tower of alkyl nitrite (the temperature in the tower is -12 ℃, and the pressure at the top of the tower is 0.1MPaG), and the 4400m 3 / h Methanol with a temperature of -10°C is sent from the top of the tower to the packed tower, and the gas mixture of the process tail gas and air and methanol are countercurrently contacted in the tower, thereby obtaining CH at the bottom of the tower 3 Methanol solution of ONO. CH 3 ONO in methanol is withdrawn from the bottom of the column and recycled to the CO carbonyl coupling synthesis of oxalate. Add 150m online to the gas mixture taken from the top of the packed column 3 / h CH 4 , and then burned in a high-temperature c...

Embodiment 2

[0066] according to figure 1 , the 1500m 3 / h contains NO 9.0% by volume, CH 3 CH 2 ONO 12.0vol%, CO 15.0vol%, N 2 O 1.1% by volume and balance N 2 CO carbonyl coupling synthesis of oxalate process tail gas with 615m 3 / h air is sent from the bottom of the tower into the packed tower as the regeneration absorption tower of alkyl nitrite (the temperature in the tower is -2 ℃, and the pressure at the top of the tower is 0.1MPaG), and the 5000m 3 / h Ethanol with a temperature of -2°C is sent from the top of the tower into the packed tower, and the gas mixture of process tail gas and air and ethanol are countercurrently contacted in the tower, thereby obtaining CH at the bottom of the tower 3 CH2 Ethanol solution of ONO. CH 3 CH 2 The ethanol solution of ONO is withdrawn from the bottom of the column and recycled to CO carbonyl coupling synthesis of oxalate. Add 175m online to the gas mixture taken from the top of the packed column 3 / h CH 4 and 10m 3 / h H 2 , and the...

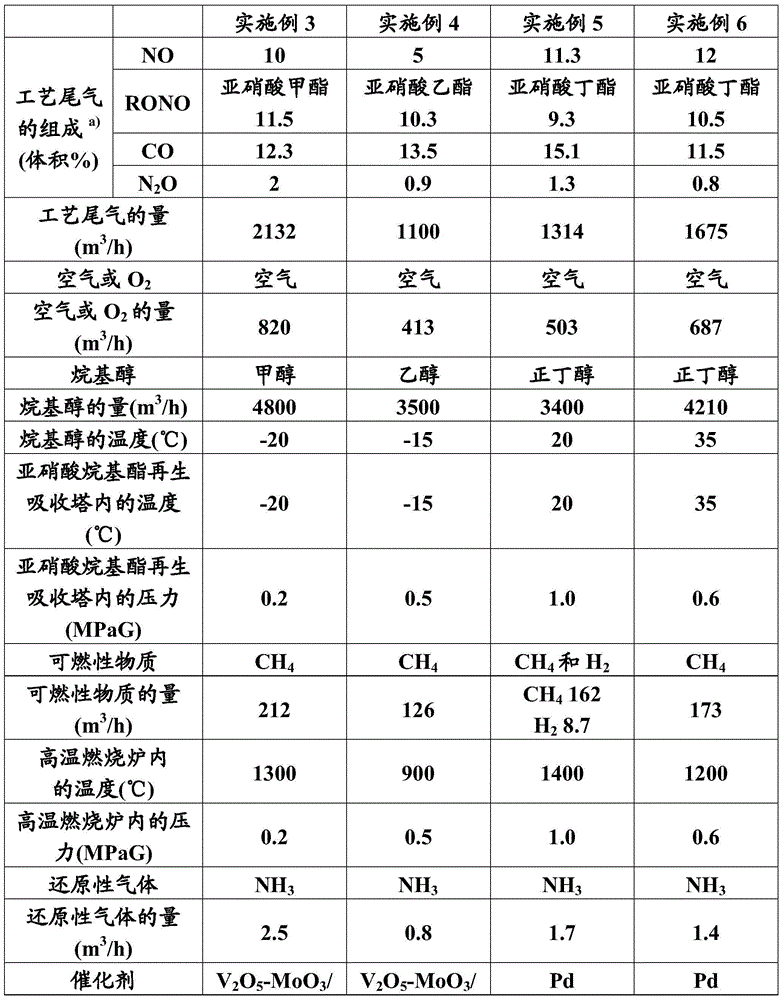

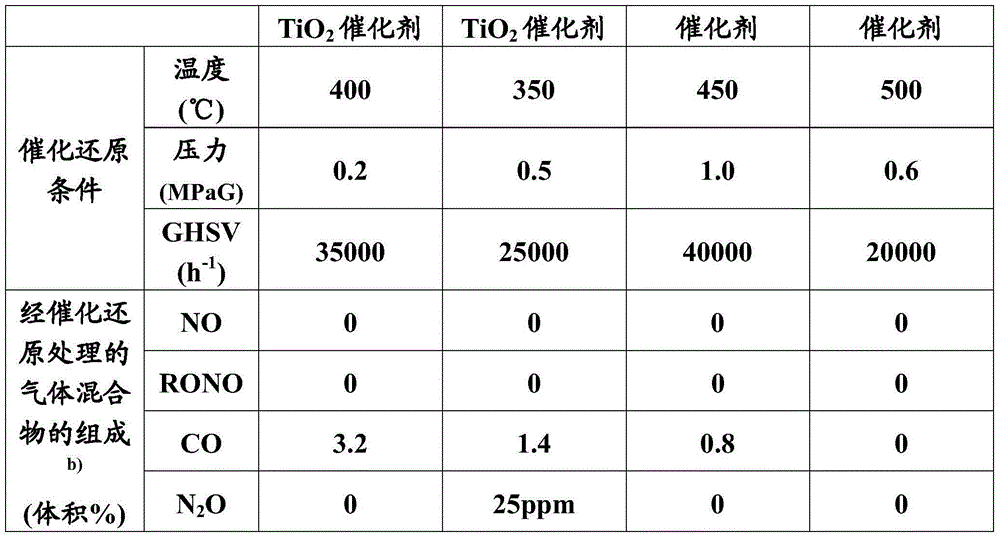

Embodiment 3-6

[0068] The reaction conditions and experimental results are shown in Table 1 below.

[0069] Table 1

[0070]

[0071]

[0072] a) The remainder is N 2 ; b) the remainder is N 2 , CO 2 and H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com