Breast pad and production method thereof

A production method and technology of breast pads, which are applied in the field of breast pads, can solve the problems of adding waterproof membranes, poor fit of breast pad edges, and increased costs, and achieve the effect of preventing external leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

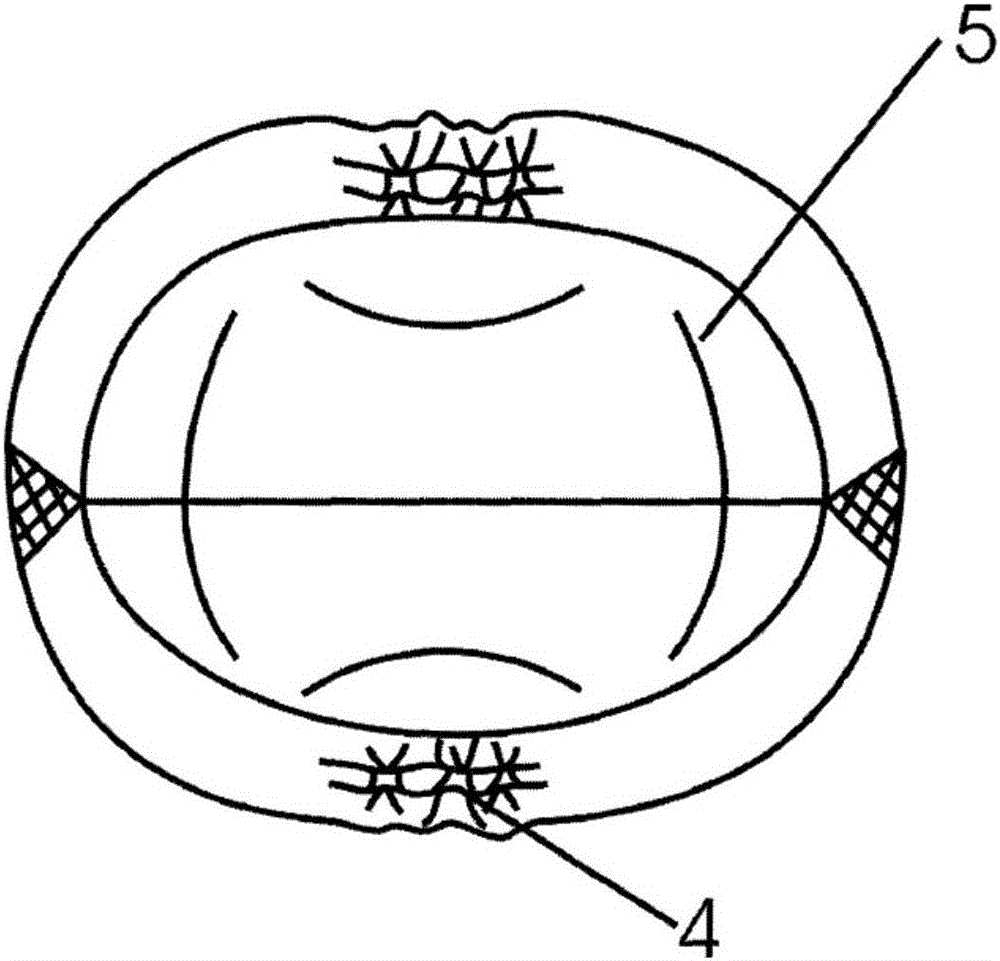

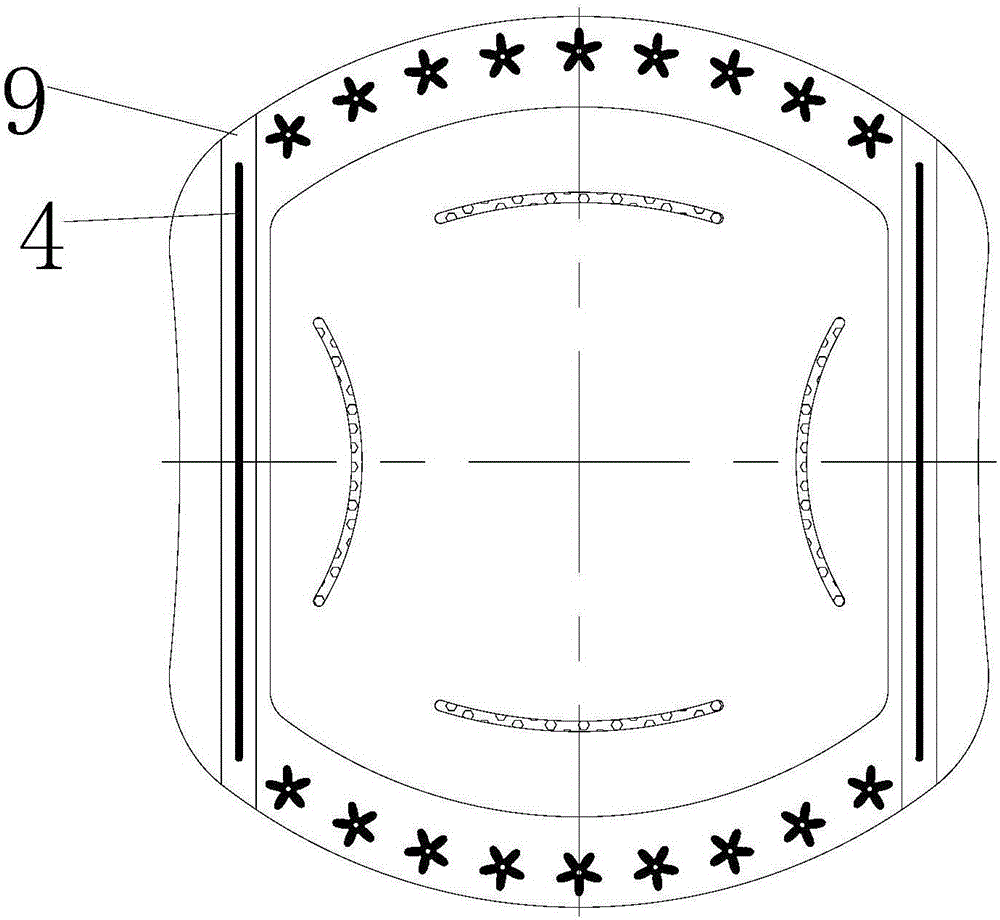

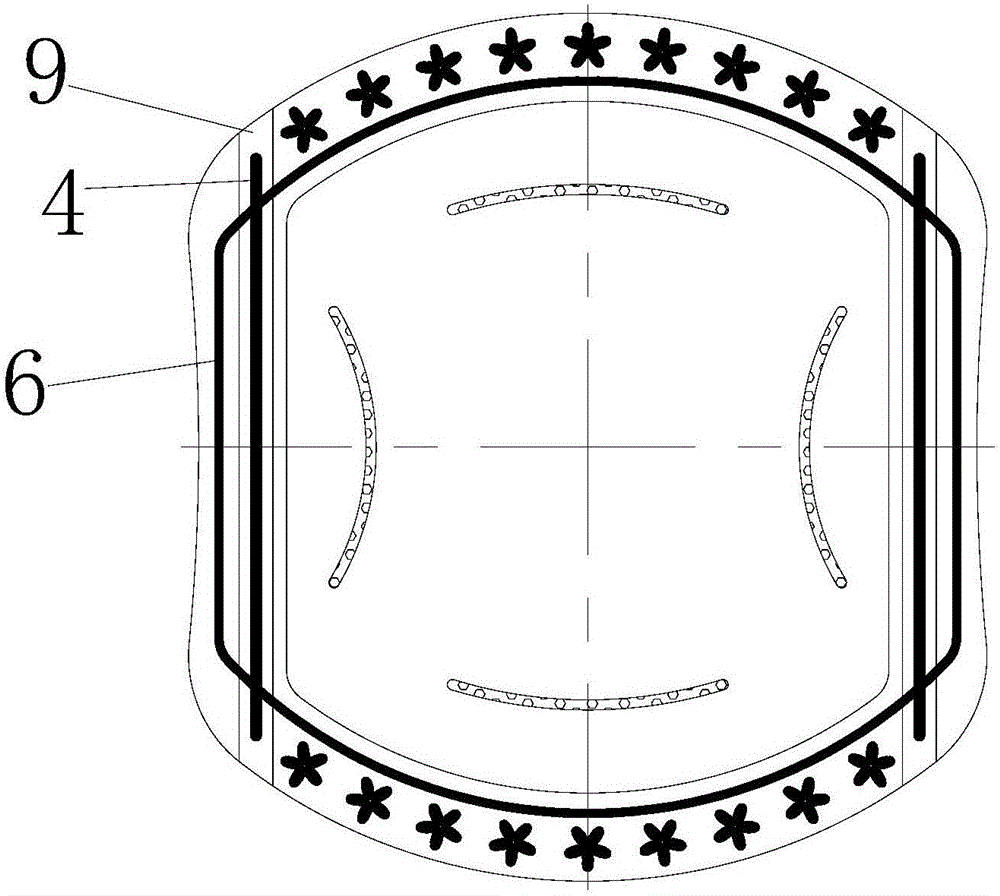

[0029] See Figure 4-6 , The breast pad of this embodiment includes: a water-conducting layer 1 (generally non-woven fabric, cotton cloth or gauze, etc.), a water-absorbing layer 2 (preferably polymer water-absorbing powder) and a waterproof layer 3 (preferably PE film) stacked in sequence or other impermeable membrane materials), and elastically shrinkable elastic bands 4 symmetrically arranged on both sides of the breast pad. There are respectively a section of pressure line 6 adopting heat-synthesis around the breast pad; two adjacent ends of each Adjacent ends of the pressure lines 6 are distributed alternately and aligned up and down.

[0030] The distance between the adjacent ends of the pressure lines adjacent to each end (generally 1.5 to 3mm) is 1-5 times the diameter of the rubber band. Due to the effect of the surface tension of the liquid, the liquid cannot smoothly pass through the curved channel with a small diameter. , thus preventing the liquid from leaking ou...

Embodiment 2

[0034] On the basis of Embodiment 1, there are the following modifications in this embodiment:

[0035] like Figure 7 , The water-absorbing layer 2 can wrap the toilet paper 7 and the non-woven fabric 8 from the inside out to prevent the leakage of the polymer water-absorbing powder. The bottom of the waterproof layer 3 is provided with a plurality of release papers 10 .

Embodiment 3

[0037] The production method of the breast pad described in the embodiment 1 or 2 includes:

[0038] A. Between the water-conducting layer 1 and the waterproof layer 3 that are continuously distributed in a straight line, the water-absorbing layer 2 is arranged in a straight line at equal intervals, and between the water-conducting layer 1 and the waterproof layer 3, on the water-absorbing layer 2 Both sides are respectively pierced with elastic bands 4 of continuous length;

[0039] B. Roller pressing equipment is used to heat-synthesize a section of pressure line 6 around the water-absorbing layer 2; the adjacent ends of the two pressure lines 6 adjacent to the ends are alternately up and down, and aligned up and down, so that on the breast pad production line 1. When the continuous elastic 4 is not cut, the continuous elastic 4 only passes through the gap between the two adjacent ends in the form of a curve;

[0040] C. The elastic 4, the water-conducting layer 1 and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com