A connection assembly between a battery tab and a cover plate

A technology for connecting components and battery tabs, applied in battery pack components, electrical components, circuits, etc., can solve the problems of reducing battery current flow and increasing resistance, increasing current flow and improving production efficiency , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific drawings.

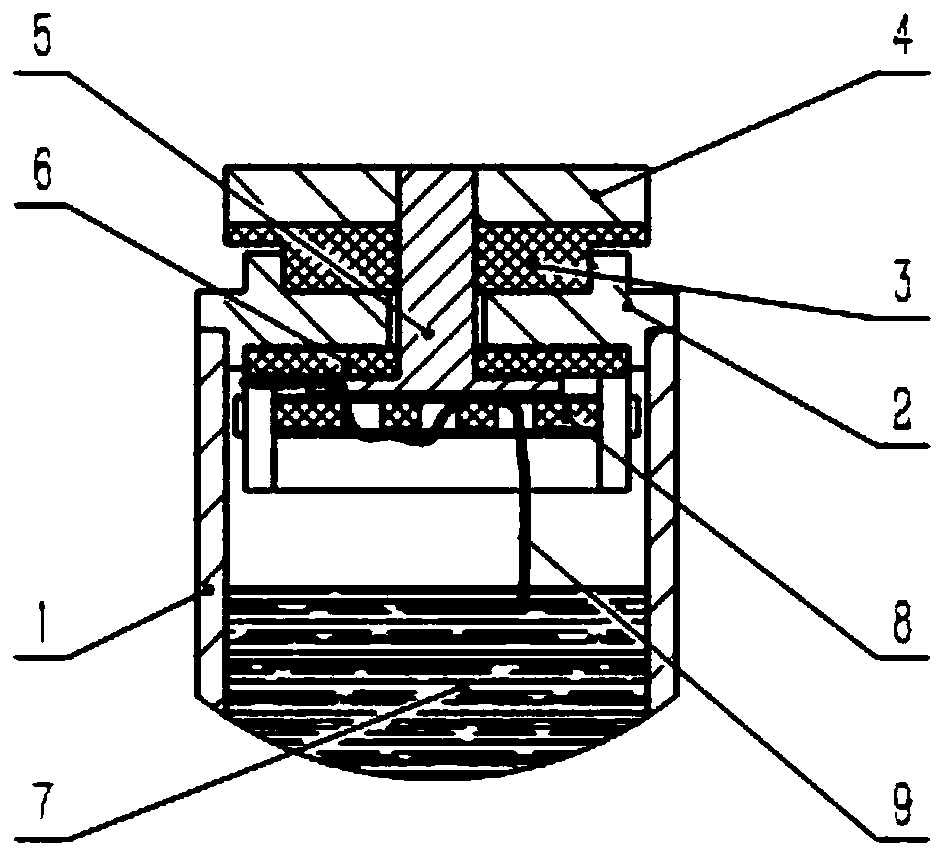

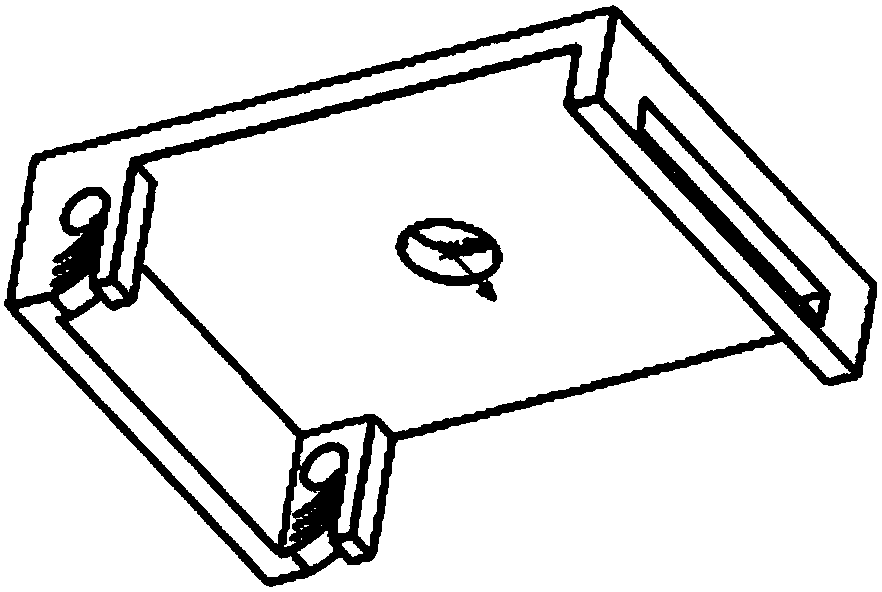

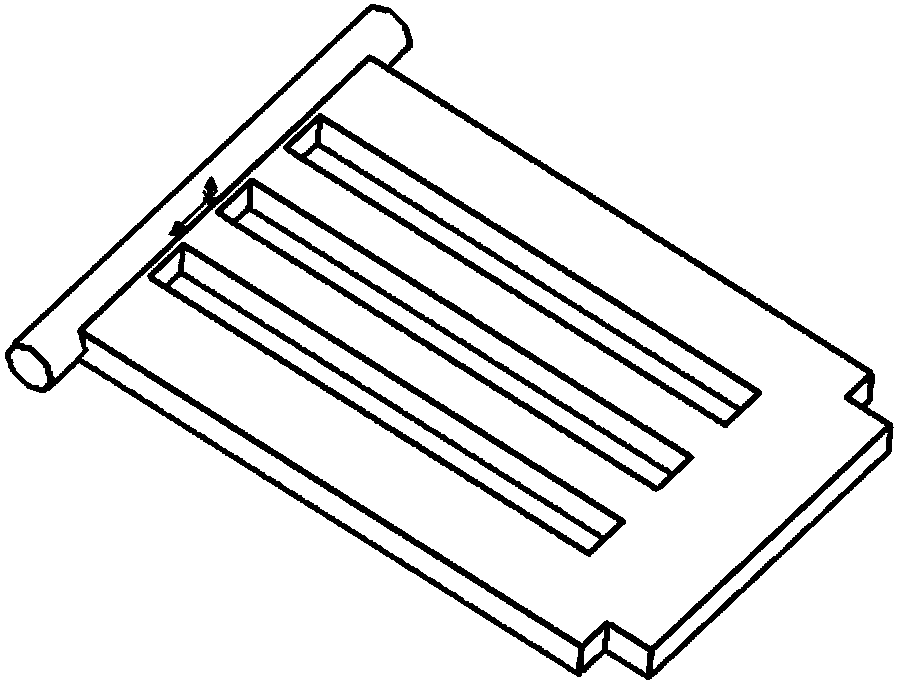

[0020] Such as 1, figure 2 , image 3 As shown, a connecting assembly of battery tabs and cover plate includes a holder 6, a holder 5 and a tab group 9. The cover plate of the holder 6 is provided with a circular through hole. The holder 5 has an inverted T-shaped structure. The holder 5 passes through the round through hole on the cover plate of the holder 6. Fixedly connected together. Preferably, the holding member 5 is a rivet. The holder 6 is equipped with a pressing piece 8 for winding and squeezing the tab assembly 9. One end of the pressing piece 8 is a shaft-shaped structure and the other end is a rectangular structure; one end of the holder 6 is opened for A circular through hole matched with the axial structure of the pressing plate 8 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com