Bearing inner ring automatic hole measuring machine

A technology of bearing inner ring and measuring hole, which is applied to measuring devices, instruments, sorting and other directions, can solve the problems of inconvenient model change, easy rollover of moving materials, and high tooling cost, and achieves convenient model change, reliable material transfer, and tooling. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

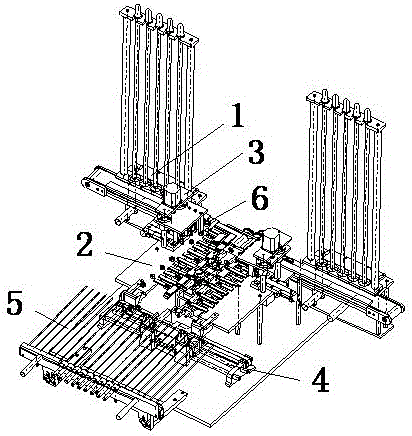

[0032] Example: see figure 1 , figure 2 In this embodiment, two sets of automatic hole measuring devices for inner rings of bearings are combined and installed on the same machine base plate, sharing an electric box, a stepping material transfer drive mechanism and a distribution drive mechanism. The main mechanisms, devices and principles of the two sets are the same. Each set is provided with two inner hole measuring instruments, and the technical scheme of one of them automatic hole measuring devices is described further in detail below.

[0033] An automatic hole measuring machine for the inner ring of a bearing, comprising a feeding mechanism 1, a stepping and shifting mechanism 2, a measuring mechanism 3 and a classification storage device, wherein the feeding mechanism 1 includes a material rack 12, a stringer rod 13, a material guide sleeve 14 and Conveyor belt 11, stringing material rod 13 is hung on the material rack 12, material guide sleeve 14 is arranged under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com