Double-power transmission

A transmission and dual-power technology, which is applied in the field of dual-power transmissions, can solve the problems of large installation space, poor electric power continuity, and heavy overall weight, and achieve the advantages of small installation space, good power output characteristics, and reduced material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

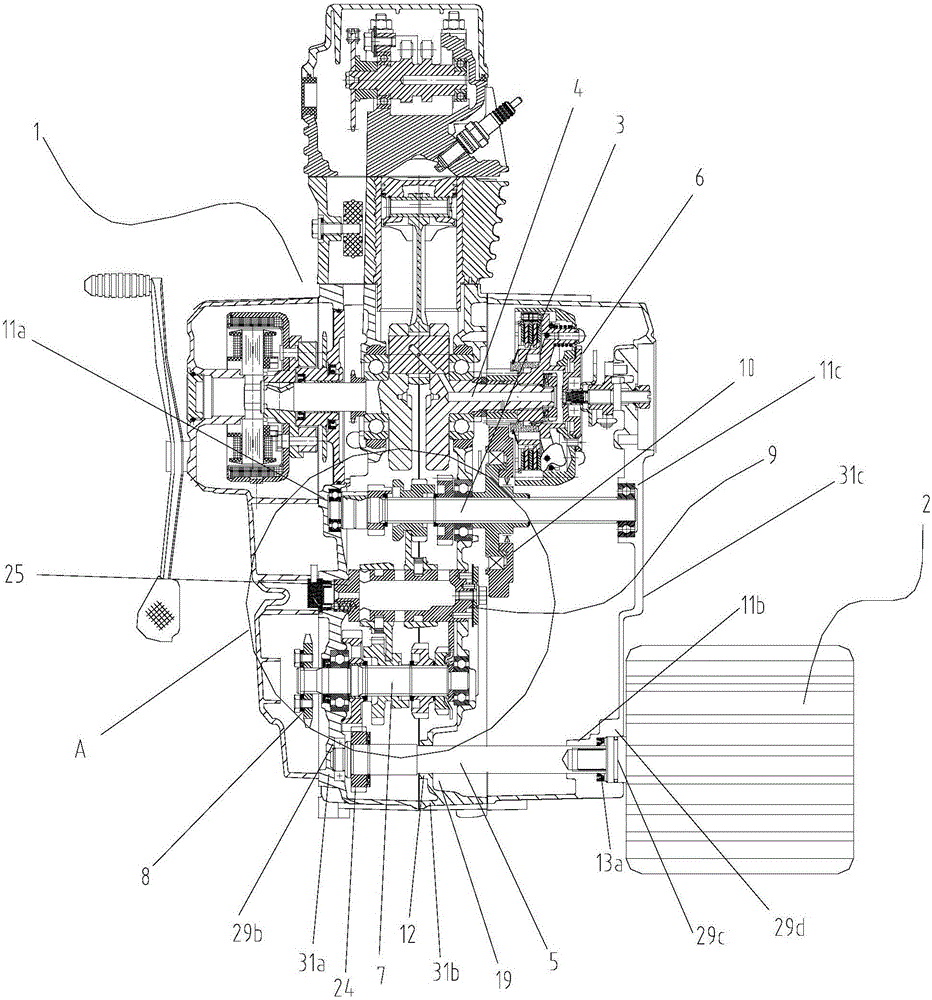

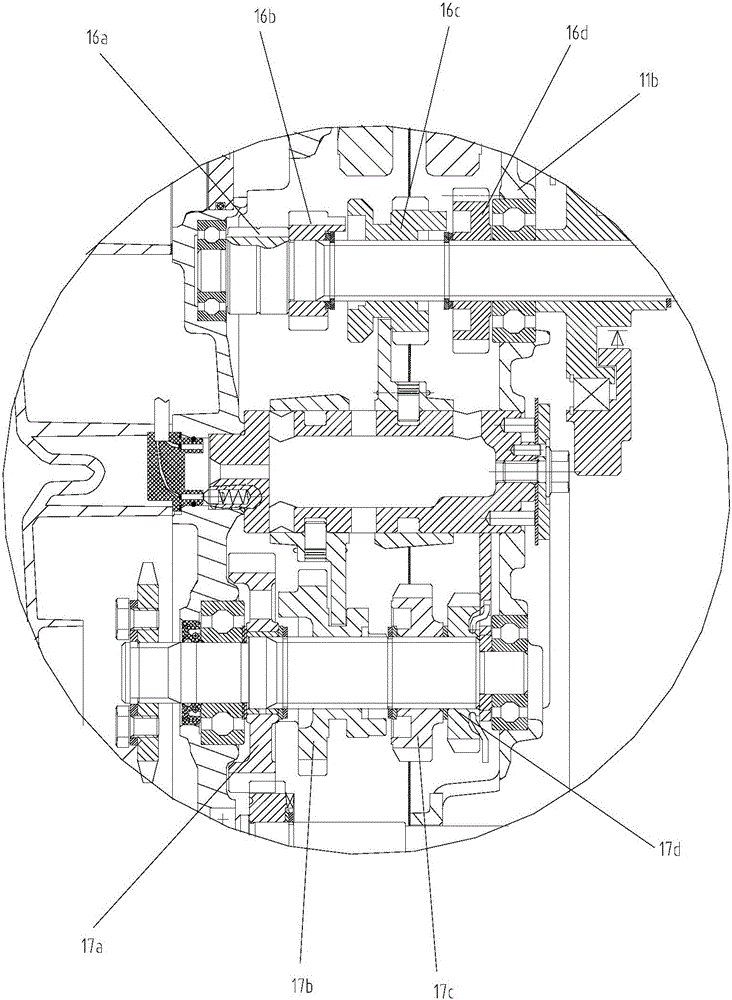

[0019] figure 1 It is a schematic diagram of the transmission structure of the present invention, figure 2 for figure 1 In the enlarged view of A, as shown in the figure, the dual power transmission in this embodiment includes the first power input member, the second power input assembly, the power input shaft and the power input shaft through the gear transmission chain gear transmission. The power output shaft; the first power input component is set on the power input shaft and input the first power in a way that the power can be overridden, and the second power input assembly is at least included in the gear transmission chain as one of the active The second power input gear 1 of the gear, the second power input gear 1 is matched with the power input shaft transmission and inputs the second power; the first power device is a fuel engine 1, and the second power device is used for the second power input The motor 2, the crankshaft 4 of the fuel engine 1 are coupled with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com