Bottom Hole Drilling Fluid Pressure Oscillation Modulator

A drilling fluid and modulator technology, applied in the direction of drilling with vibration, etc., can solve the problems that the tool cannot be powered by the rotation of the drilling tool to provide a burden, the service life of the tool cannot be too short, and the measuring instrument while drilling cannot be used together. , The impact amplitude is very easy to adjust, and the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

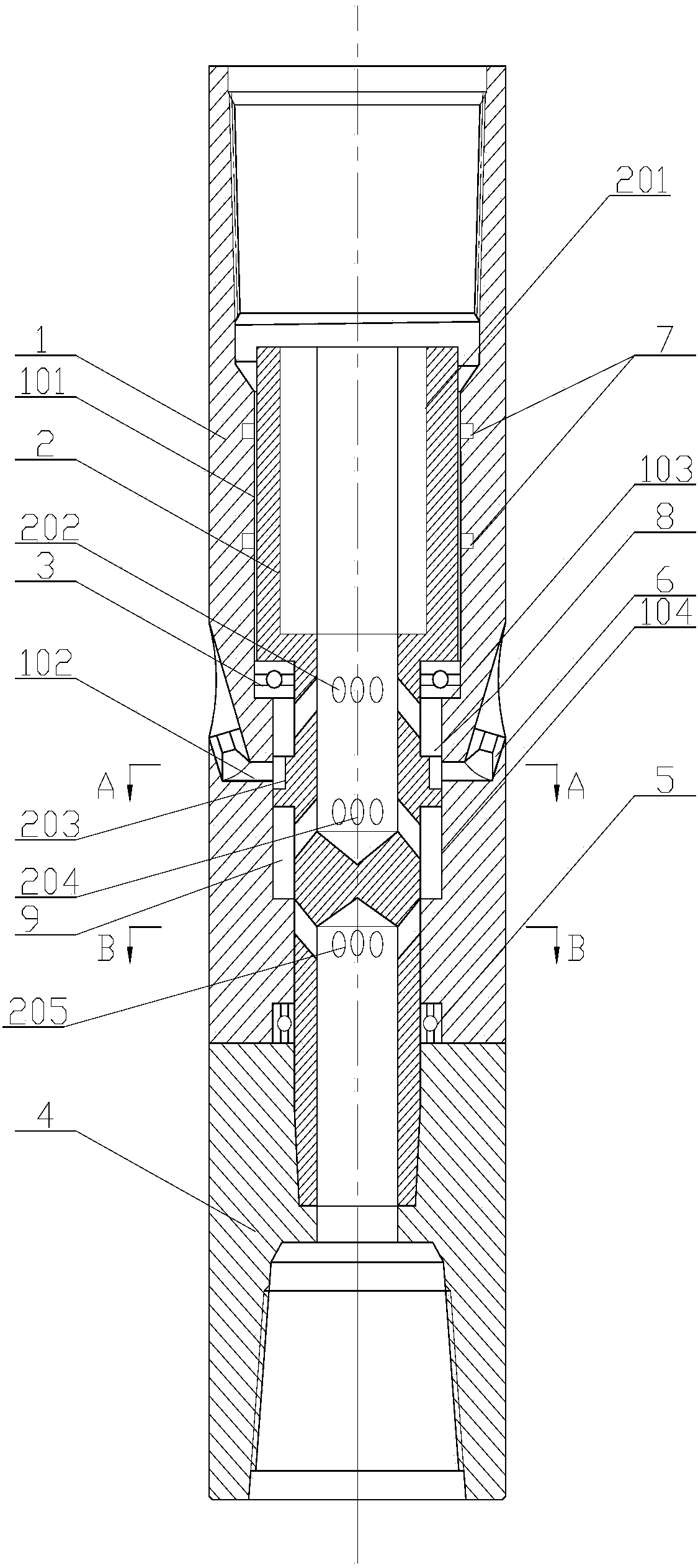

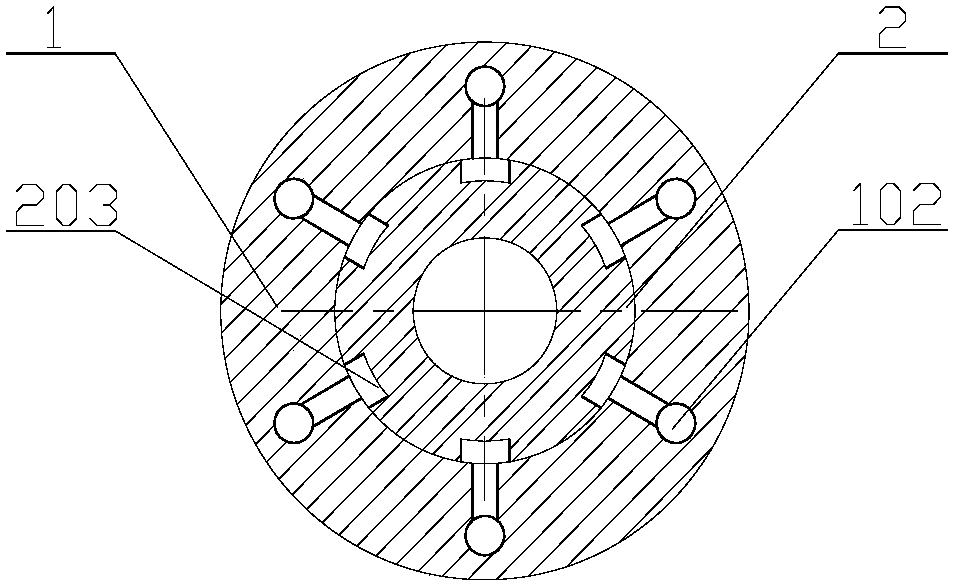

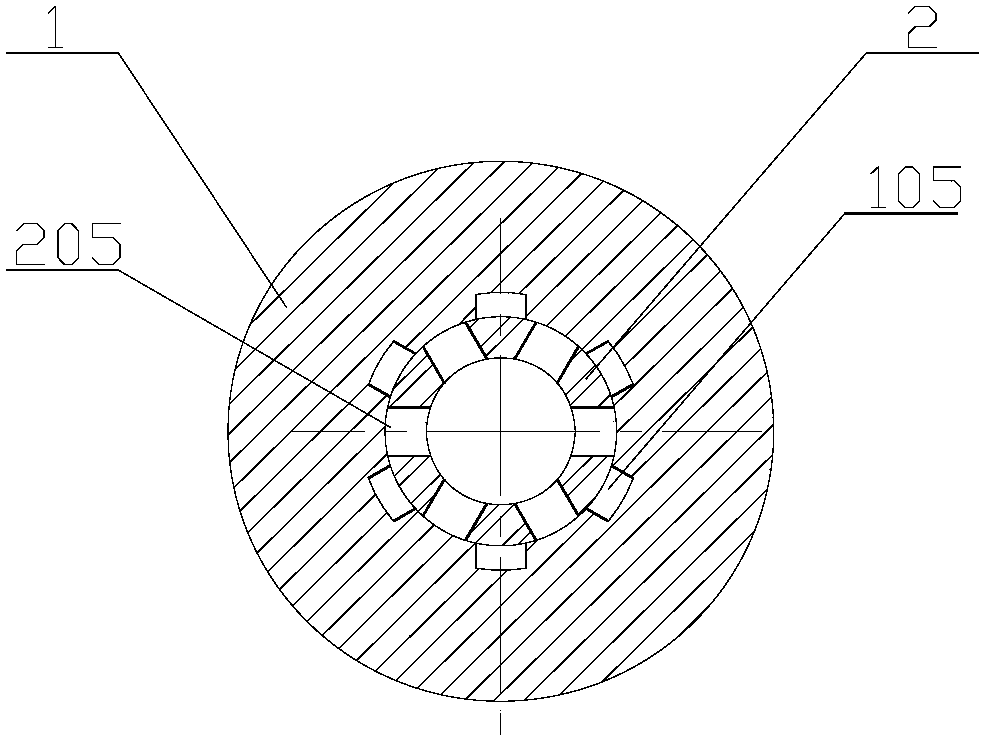

[0017] like figure 1 , figure 2 , image 3 As shown, the bottom hole drilling fluid pressure oscillation modulator includes a counterflow housing 1, an oscillating main shaft 2, and a lower joint 4; the countercurrent housing 1 is connected with the power drilling tool stator, the upper part of the oscillating main shaft 2 is connected with the power drilling tool rotor, and the lower part is connected with the power drilling tool rotor. The lower joint 4 is connected, and the connecting body of the oscillating mother shaft 2 and the lower joint 4 rotates with the power drilling tool rotor relative to the counterflow casing 1 and the power drilling tool stator connecting body.

[0018] The outside of the counterflow housing 1 is a cylindrical surface of equal diameter, and the interior is from top to bottom in order of connecting buckles for the stator of the power drilling tool, the centering circular surface 101 of the counterflow housing, the anti-pressure ring surface 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com