A construction method of external cladding for overall prefabricated buildings based on bim technology

A construction method and technology of external hanging panels, which are applied in the processing of building materials, construction, building construction, etc., can solve the problems of high construction cost and insufficient overall strength of external hanging panels, achieve strong earthquake resistance, increase the cost of redundant materials and man-hours , High-quality effect of steel bar binding and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

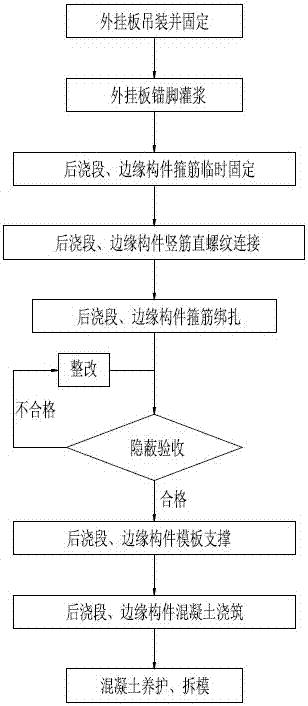

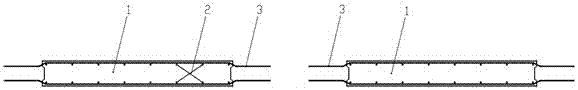

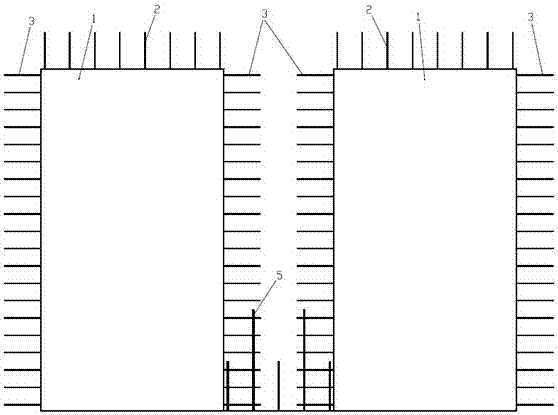

[0045] Such as Figure 1 to Figure 7 As shown, in this embodiment, the construction method of the external hanging panels of the overall prefabricated building based on BIM technology is used for the post-casting section construction between the external hanging panels. The specific construction steps are as follows:

[0046] (1) Hoist the external hanging plate 1 in place and temporarily fix it, and adjust the verticality;

[0047] (2) Grouting of the anchor foot of the external hanging plate 1; connect the external hanging plate with the floor slab that has been constructed, and fix the external hanging plate;

[0048] (3) install the stirrup 4 within the scope of the post-casting section, and temporarily fix the stirrup 4 and the external hanging plate 1, and the stirrup 4 is a closed rectangular stirrup;

[0049] (4) Install vertical reinforcement 5 within the scope of stirrup 4, and connect and lengthen the length of vertical reinforcement 5 according to the floor height; ...

Embodiment 2

[0061] Such as figure 1 , 13 As shown in ab3701-ef5d-4755-b1e7-a8b12eb5e519, the construction method of the external cladding of the overall prefabricated building based on BIM technology in this embodiment is used for the construction of the edge components between the cladding panels. The specific construction steps are as follows:

[0062] (1) Hoist the external hanging plate 1 in place and temporarily fix it, and adjust the verticality;

[0063] (2) Grouting of the anchor foot of the external hanging plate 1; connect the external hanging plate with the floor slab that has been constructed, and fix the external hanging plate;

[0064] (3) install stirrups 4 within the scope of the edge member, and temporarily fix the stirrups 4 and the external hanging plate 1, and the stirrups 4 are closed rectangular stirrups;

[0065] (4) Install vertical reinforcement 5 within the scope of stirrup 4, and connect and lengthen the length of vertical reinforcement 5 according to the floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com