Reinforcing method and structure for retaining wall

A technology for strengthening structures and retaining walls, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of troublesome construction and high cost, achieve the effects of reducing waste, ensuring safety requirements, and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

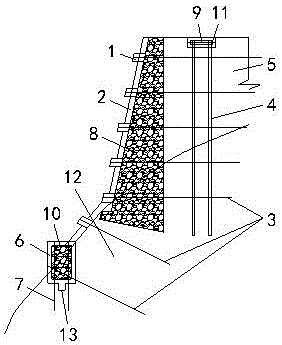

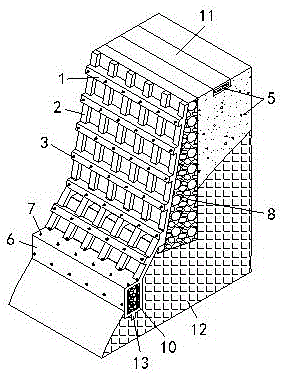

[0020] This example Figure 1-3 As shown, it is composed of lattice beams 1, lattice vertical beams 2, thin-walled cavity bases with tenons 6, anchor rods 3, prefabricated bamboo hollow crown beams 11 and prefabricated bamboo cavities 4 paired. Support reinforcement structure. The thin-walled cavity base 6 with tenons is filled with graded homogeneous stones 10 . The lattice beam 1, the lattice vertical beam 2 and the thin-walled cavity base 6 with tenons are all reinforced concrete components. The slope of the retaining wall 8 to be reinforced should be roughened. The prefabricated bamboo hollow crown beam 11 and the prefabricated bamboo cavity 4 should be constructed first to pre-reinforce the original soil body 5 at the back of the retaining wall, and then the anchor rod 3 should be constructed to form an effective tie with the interior of the retaining wall 8 to be reinforced. , the outer end of the anchor rod 3 should be connected to the intersection point of the latti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com