Cylindrical surface triangular central symmetry arrayed electrostatic spinning spray head and spinning method

A centrosymmetric, electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as uneven spinning, large difference in electric field of nozzles, interference, etc. The effect of small intensity differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

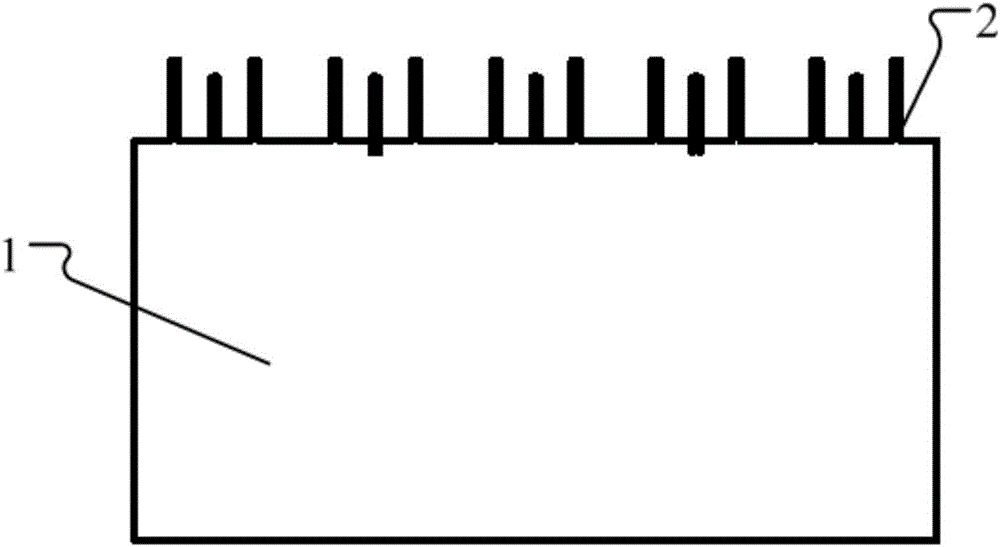

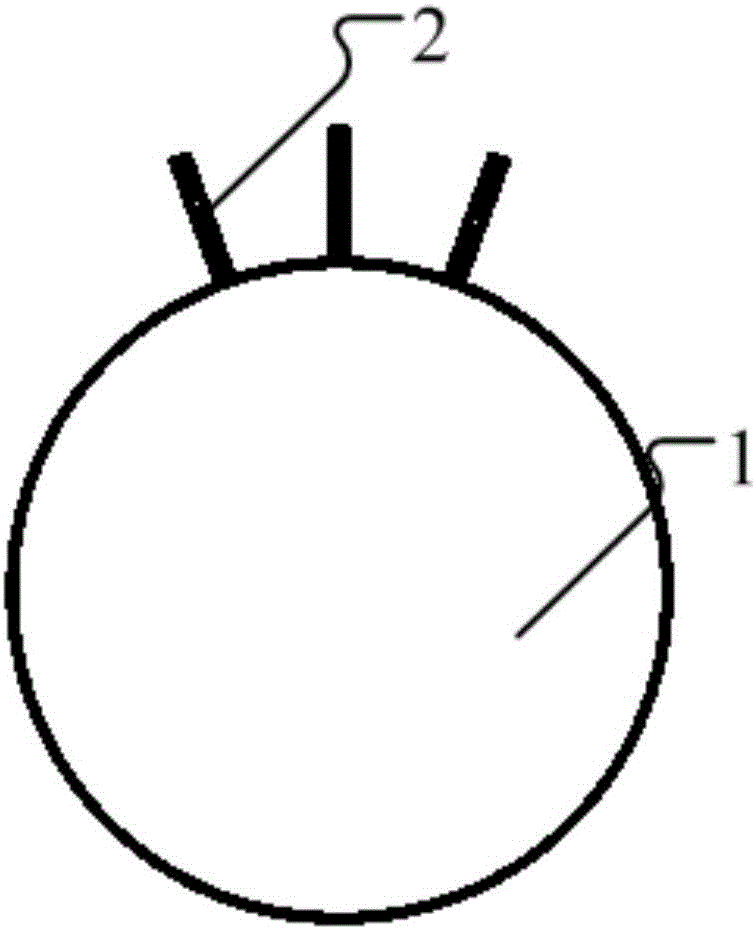

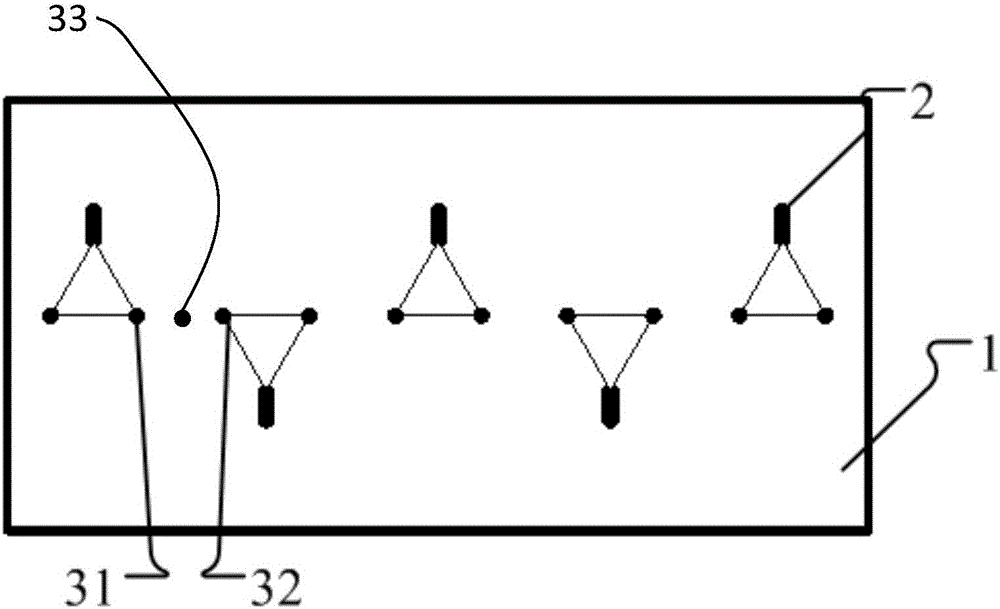

[0027] Such as Figure 1 to Figure 3 The electrospinning nozzle of the cylindrical triangular centrosymmetric array shown includes a body 1, the body 1 has a cylindrical surface at the top and is provided with at least three sets of output structures, and the output structures are used to collect and spray spinning solution .

[0028] Each set of output structure is composed of three connecting holes on the cylindrical surface and needle nozzles 2 respectively connected to the connecting holes. The connecting holes in the drawings coincide with the needle nozzles 2, so the connecting holes are in figure 1 with figure 2 Not marked in . The connecting lines of these three connecting holes form a triangular trajectory, that is, the three connecting holes are on the endpoints of a triangle, and the connecting line segments of two connecting holes are parallel to the axis of the cylindrical surface. In other words, by this One of the sides of the triangle formed by the three co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com