A novel ubenimex recrystallization method

A technology for ubimethoxine and ubimethoxine hydrochloride, which is applied in the field of medicine, can solve the problems that the overall yield does not meet the production requirements, the agitator motor is easily damaged, and the agitator cannot operate, and the production process is easy to control and increase. Yield, the effect of avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

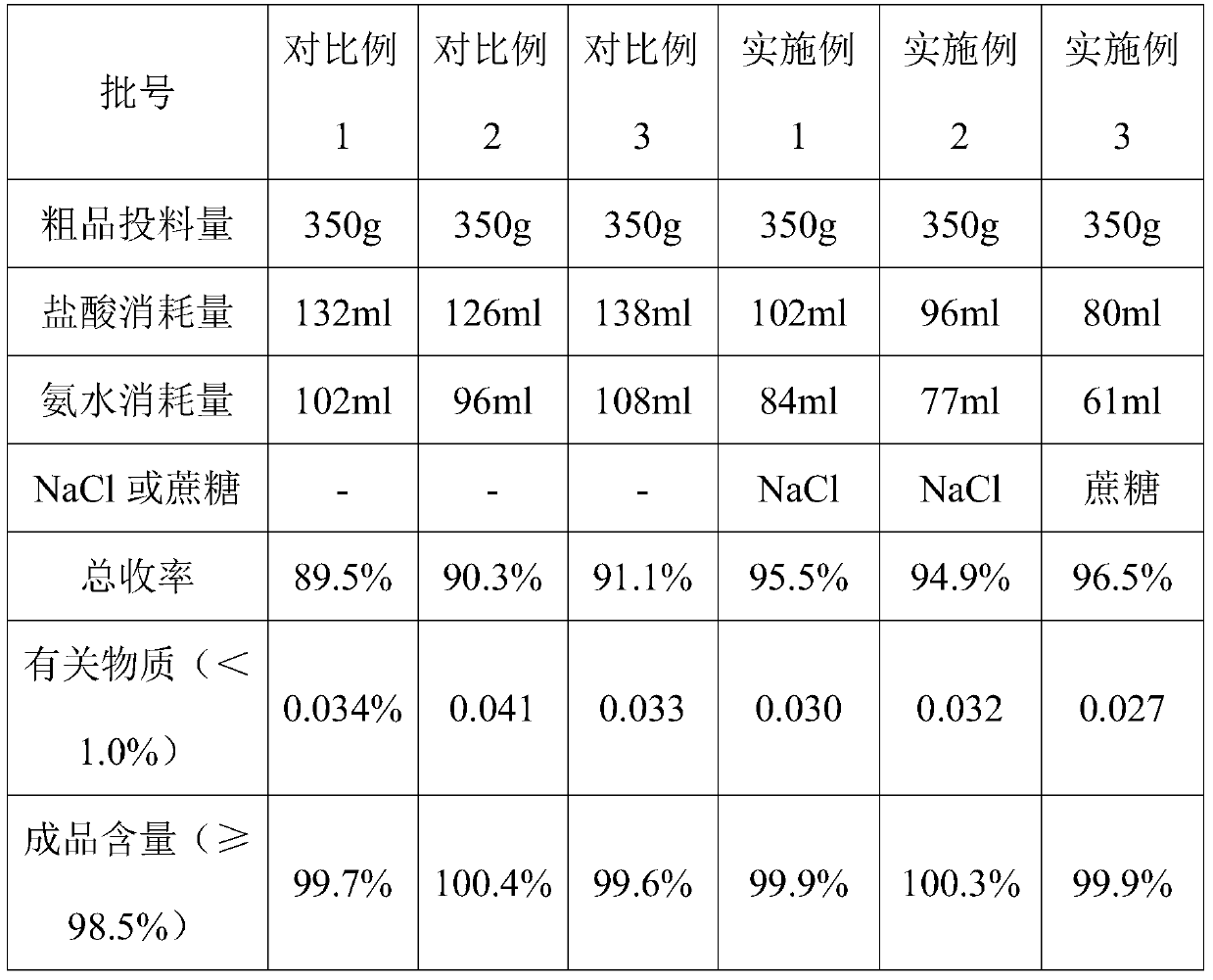

Embodiment 1

[0029] (1) Add 1000ml of sodium dihydrogen phosphate / disodium hydrogen phosphate buffer solution with a pH value of 7 into a three-necked flask, add 350 g of Ubenimex crude product, stir, heat to a temperature of 60°C, and dropwise add 102 ml of 18.5% hydrochloric acid solution , the crude product was completely dissolved and filtered to obtain Ubenimex hydrochloric acid solution;

[0030] (2) Get another three-necked flask and add 2000ml of purified water, control the temperature of the system in an ice-water bath below 4°C, add dropwise ubenimex hydrochloric acid solution and 5% ammonia water at the same time, control the dropping speed of the two solutions, and make the pH of the reaction system value was kept at 5-7, the dropwise addition of the ubenimex hydrochloric acid solution was completed, the amount of ammonia water was added dropwise to 74ml, stirred and crystallized for 15h, filtered to obtain a filter cake;

[0031] (3) Filter cake The filtered filter cake was wa...

Embodiment 2

[0033] (1) Add 1000ml of sodium dihydrogen phosphate / disodium hydrogen phosphate buffer solution with a pH value of 7 into a three-neck flask, add 350 g of Ubenimex crude product, and add 1.7 g of sodium chloride solid, stir, and heat to a temperature of 60°C , 96ml of 18.5% hydrochloric acid solution was added dropwise, the crude product was completely dissolved, filtered to obtain ubenimex hydrochloric acid solution;

[0034] (2) Get another three-necked flask and add 2000ml of purified water, control the temperature of the system in an ice-water bath below 4°C, add dropwise ubenimex hydrochloric acid solution and 5% ammonia water at the same time, control the dropping speed of the two solutions, and make the pH of the reaction system value was kept at 5-7, the dropwise addition of the ubenimex hydrochloric acid solution was completed, the amount of ammonia water added was 77ml, stirred and crystallized for 15 hours, filtered to obtain a filter cake;

[0035] (3) Filter cake...

Embodiment 3

[0037] (1) Add 1000ml of sodium dihydrogen phosphate / disodium hydrogen phosphate buffer solution with a pH value of 7 into a three-necked flask, add 350g of Ubenimex crude product, and add 3.5g of sucrose, stir, heat to a temperature of 60°C, add dropwise 80ml of 18.5% hydrochloric acid solution, the crude product was completely dissolved, filtered to obtain ubenimex hydrochloric acid solution;

[0038] (2) Get another three-necked flask and add 2000ml of purified water, control the temperature of the system in an ice-water bath below 4°C, add dropwise ubenimex hydrochloric acid solution and 5% ammonia water at the same time, control the dropping speed of the two solutions, and make the pH of the reaction system value was kept at 5-7, the dropwise addition of the ubenimex hydrochloric acid solution was completed, the amount of ammonia water was added dropwise to 61ml, stirred and crystallized for 15h, filtered to obtain a filter cake;

[0039] (3) Filter cake The filtered filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com