Colorful self-leveling porous sidewalk surface material and preparation method thereof

A self-leveling and sidewalk technology, applied in the field of asphalt pavement materials, can solve the problems of not having large gaps, water permeability, water storage functions, not having the ability to alleviate urban heat islands, and unable to store water, so as to alleviate urban heat island effects, reduce construction costs, Good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with specific embodiments.

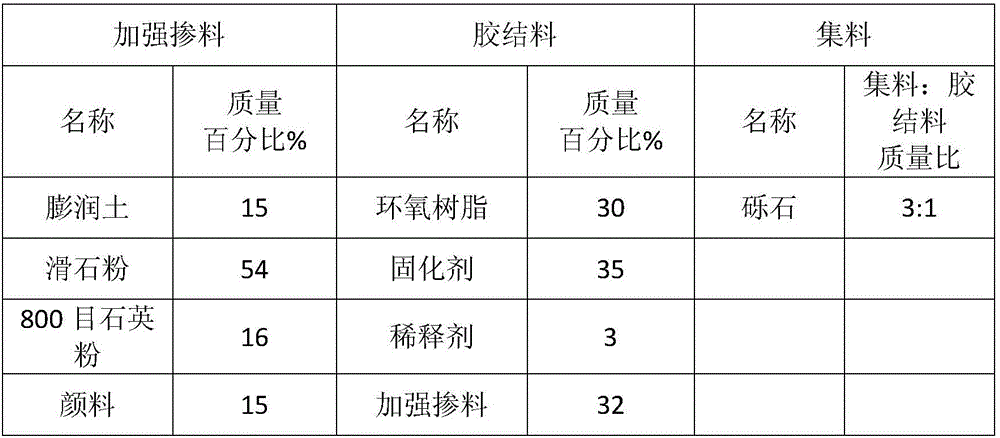

[0017] A colored self-leveling porous pavement surface material of the invention is mainly composed of cementing material and aggregate. The mass percent composition of the cement is as follows: 25-50% of epoxy resin, 10-30% of diluent, 30-50% of curing agent, and 15-40% of reinforcing material. The mass percentage composition of the reinforcing admixture is as follows: 10-30% of bentonite, 50-80% of talcum powder, 10-30% of 800-mesh quartz powder, and 10-30% of pigment. The aggregate is single grade limestone aggregate or gravel, and the particle size of the aggregate is between 9mm and 11mm. The ratio of single grade aggregate to cementitious material is 2.5:1~3.5:1. The epoxy resin is an oily epoxy resin, and the curing agent is a modified amine curing agent. The diluent is diethylene glycol glycidyl ether.

[0018] The preparation method of colored self-leveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com