Automatic screw locking device for moulded case circuit breaker

A molded case circuit breaker and automatic locking technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as poor product consistency, unstable product quality, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiments.

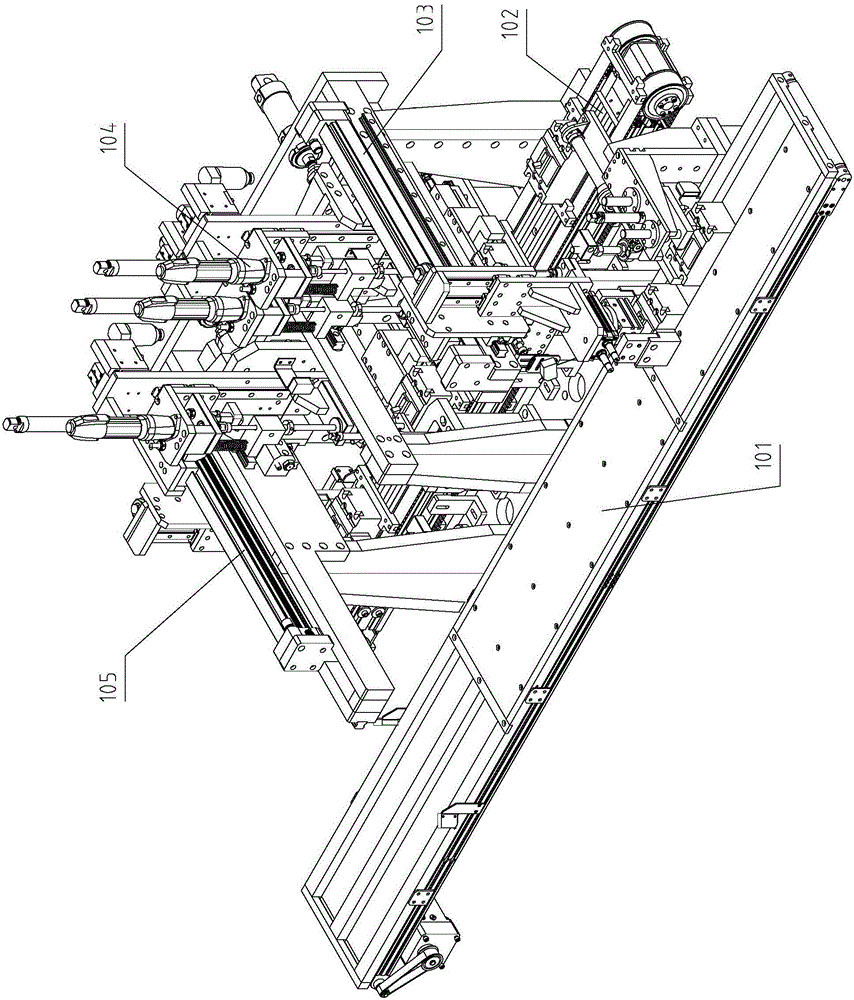

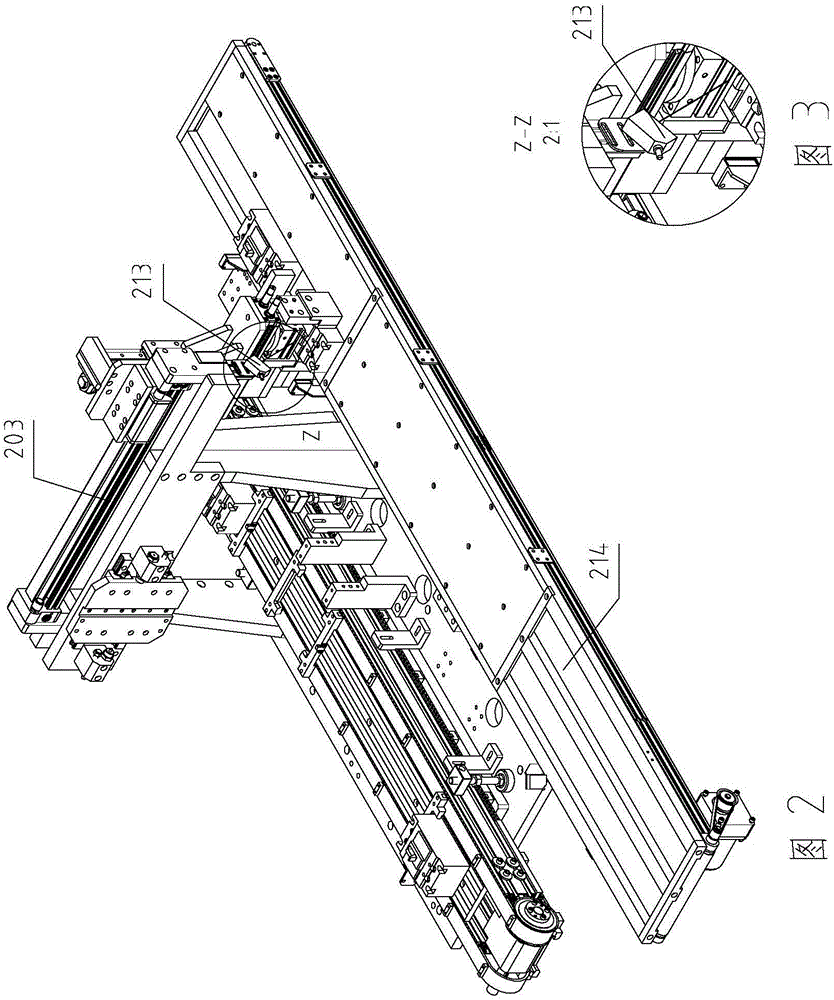

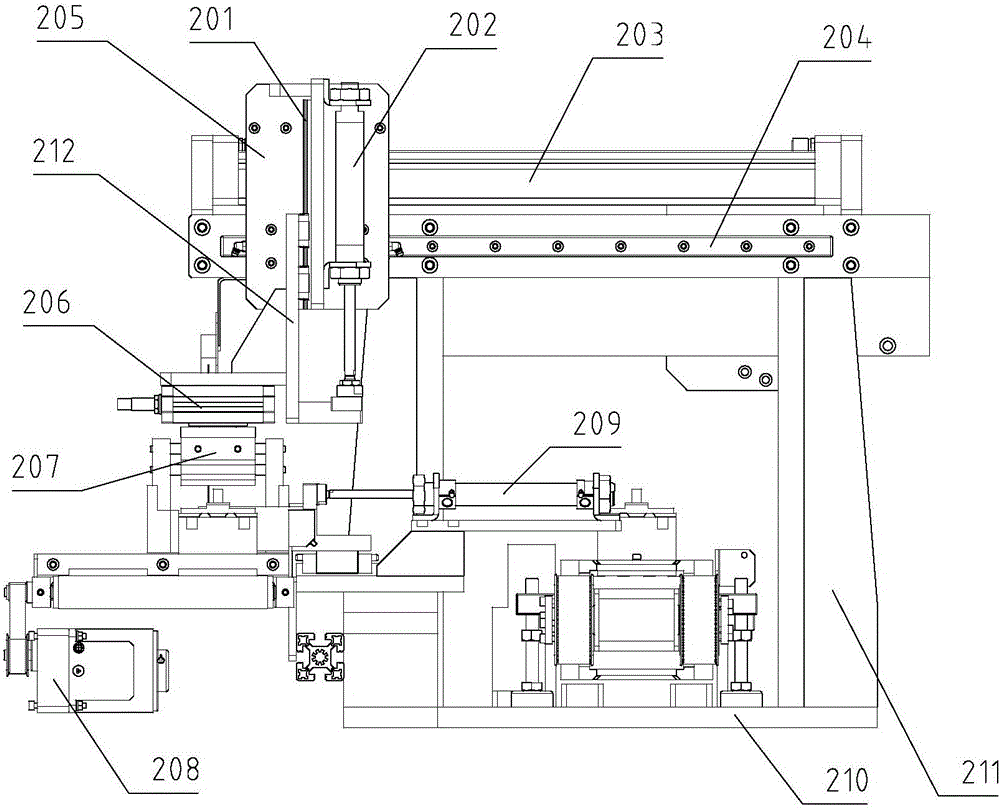

[0026] Such as Figure 1-Figure 9 Shown is an embodiment of the present invention, figure 1 It can be seen that the plastic case circuit breaker screw automatic locking device is provided with a workpiece locking assembly 104, the workpiece locking assembly 104 is provided with a support plate 309, and the support plate 309 is provided with a torque adjustable wrench 303, a torque adjustable wrench 303 is connected to the torsion shaft 306. The front end of the torsion shaft 306 is provided with a locking batch head 307. The locking batch head 307 is provided with a screw inlet 308. The supporting plate 309 is slidably connected to the vertical plate 304 through a vertical guide rail 305. There is a vertical feed cylinder 302, one end of the vertical feed cylinder 302 is connected with the support plate 309; the vertical feed cylinder 302 can push the support plate 309 to slide on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com