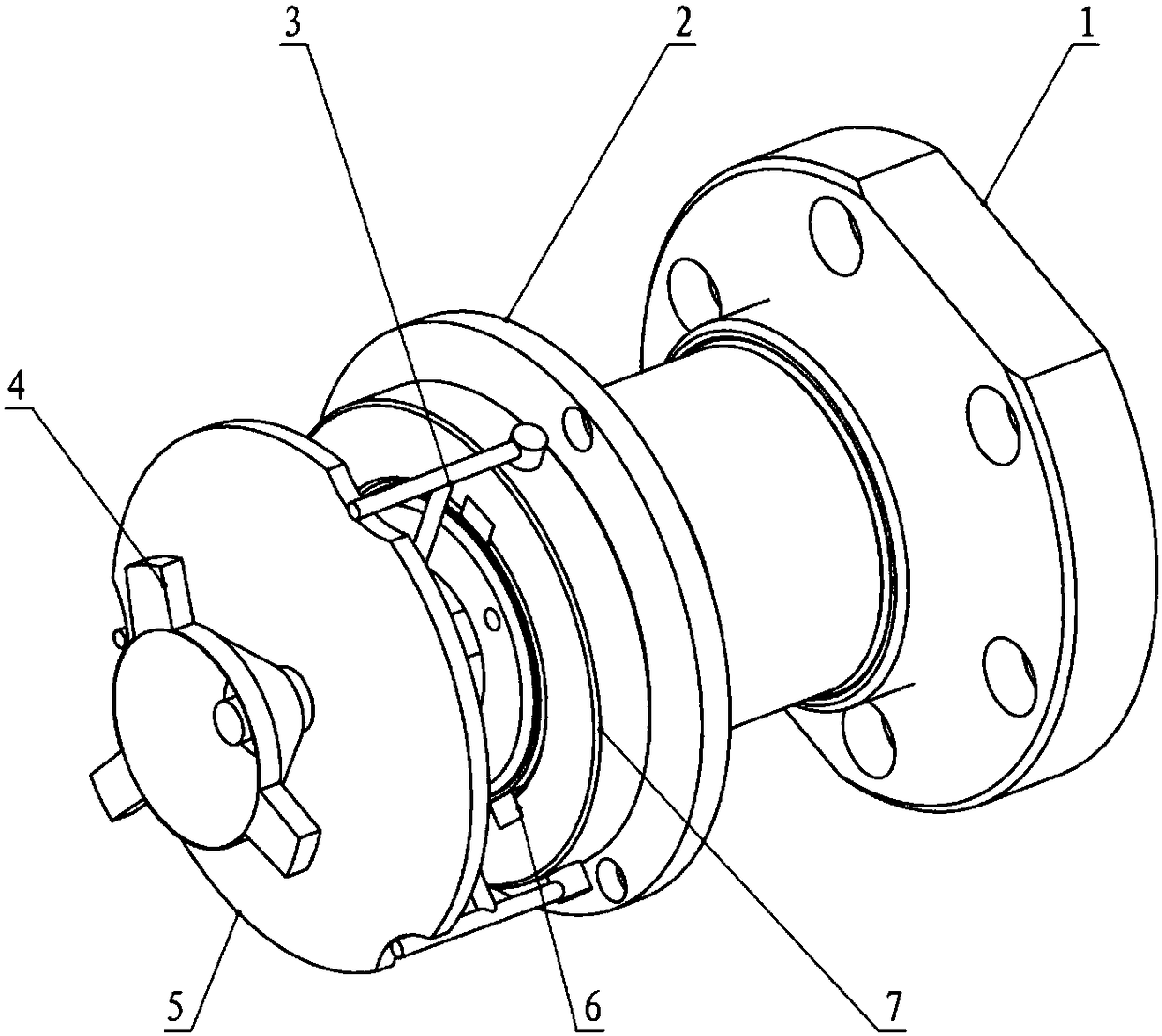

Rotary shaft mechanical locking device based on lever micro-motion principle

A technology of mechanical locking and rotating shafts, which is applied in the direction of mechanical equipment, brake parts, brake parts, etc., can solve the problems of easy damage of the locking handle, uneven locking force, and non-adjustable locking force, etc., to eliminate The locking force is uneven, the accuracy is not damaged, and the mechanical index guarantees the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

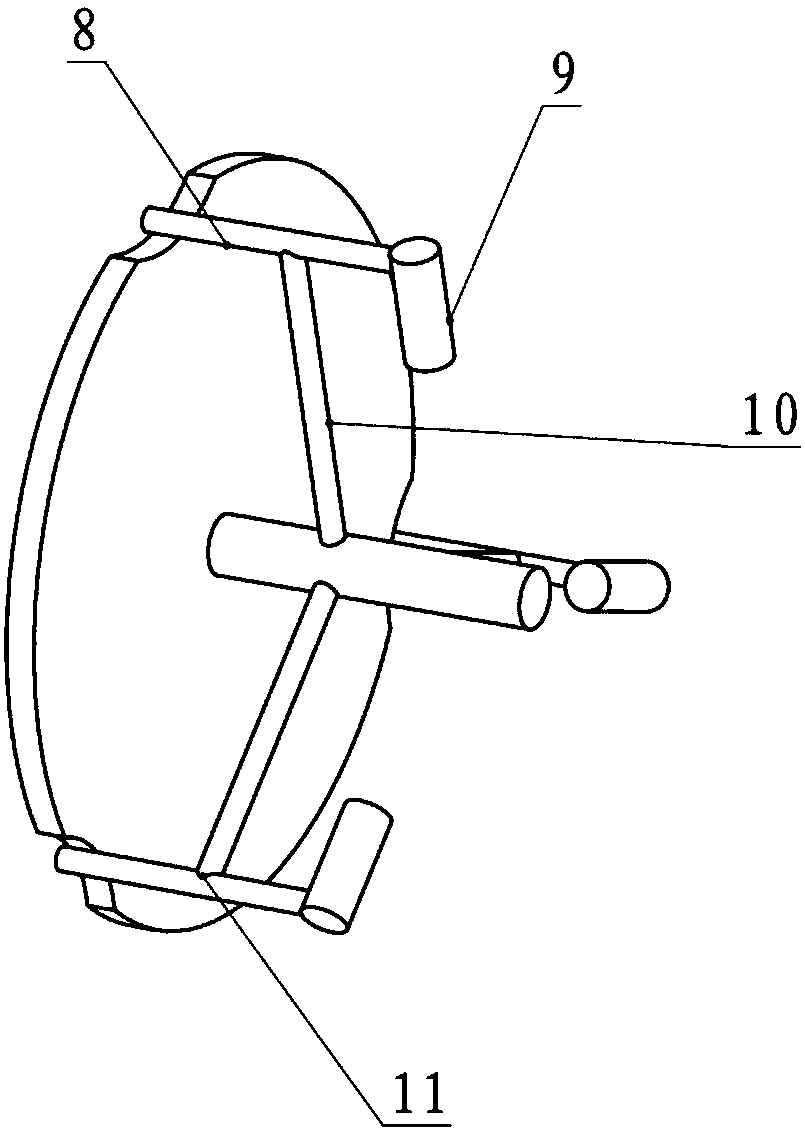

Embodiment 1

[0016] In the non-working state, shaft 1 stops rotating, and shaft 1 needs to be locked. Handwheel 4 and cam 5 are fixed together. Turn handwheel 4, cam 5 and handwheel 4 will rotate together. The lowest point of the cam moves upwards. Through the action of the lever twisting point 11, the cylindrical end 9 of the lever in the floating sleeve 7 will move downwards, transmitting the force to the pressure block 6, and then the pressure block 6 transmits the pressing force to the elastic thin film. The wall sleeve 2 and the elastic thin-wall sleeve 2 will finally compress the shaft 1 from three different directions to achieve the effect of locking the shaft 1.

Embodiment 2

[0018] Under normal working conditions, unlock the firmly locked shaft. Loosen the hand wheel and rotate the hand wheel 4 in the opposite direction. The hand wheel 4 and the cam 5 are fixed together, and the cam 5 will move in the opposite direction. At this time, the tension of the tensioned lever device 3 is released, and the lever assembly 3 will return to its balance In the state, the pressure received by the pressure block 6 disappears, the elastic thin-wall sleeve loosens the tightly held shaft, the shaft 1 is unlocked, and the shaft will work normally under the driving torque of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com